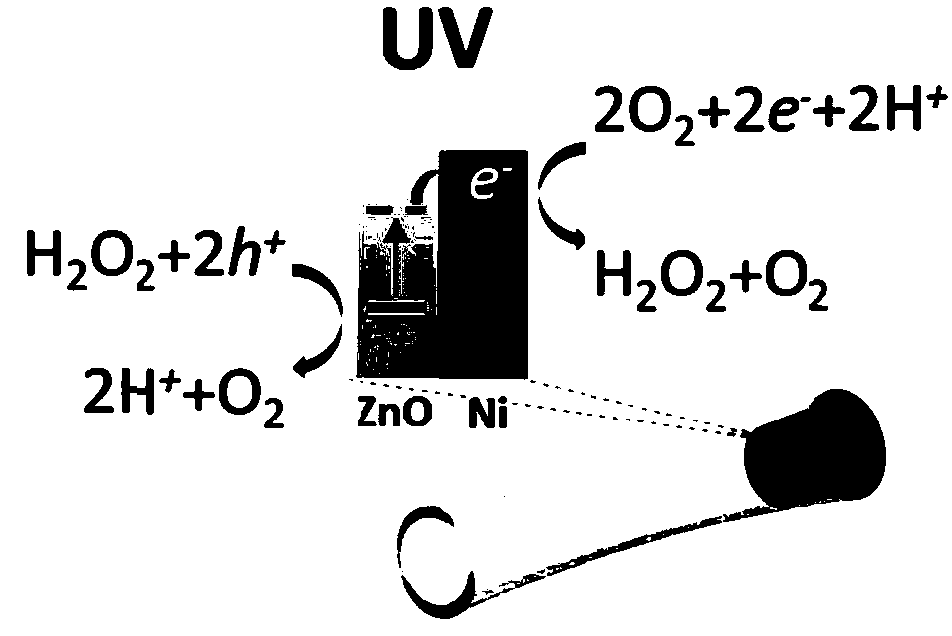

ZnO-Ni photic driving micropipe motor and preparation method thereof

A light-driven and motor technology, applied in the field of micro-nano, can solve the problems of restricting the application range of motors, high cost, and insufficient motion performance, and achieve the effects of good application prospects, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

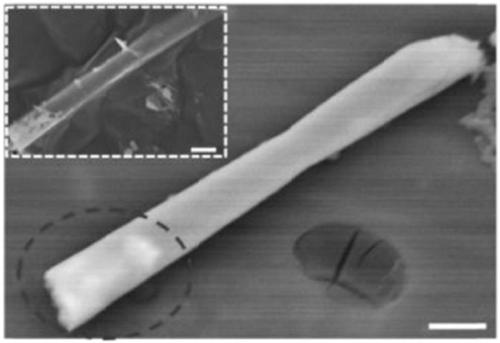

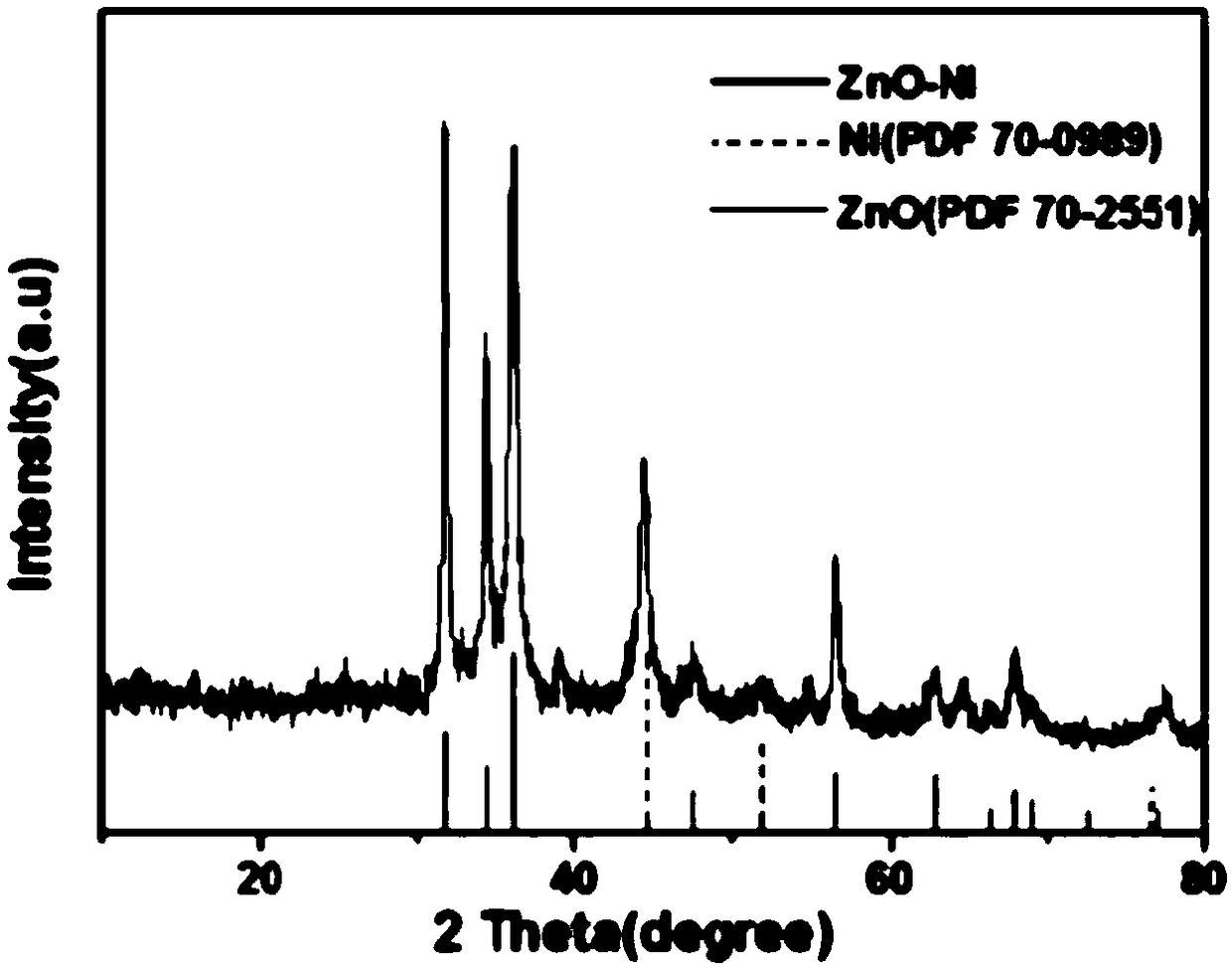

[0030] A preparation method of ZnO-Ni light-driven microtube motor:

[0031] 1) Using the method of atomic layer deposition, the polycarbonate with a pore size of 2 μm is placed in the atomic layer deposition equipment, and at 120 ° C, using diethyl zinc and who is the precursor, the pulse is alternately carried out for 1200 cycle reactions, and the deposition ZnO;

[0032] 2) Plating a layer of gold on the polycarbonate template containing ZnO with a magnetron ion coating device, the thickness of the metal layer is about 80nm, assembled in the electroplating tank, contacting the gold-plated surface of the polycarbonate film with copper foil, and connecting the electric The chemical workstation is used as the working electrode, the platinum electrode is used as the counter electrode, and the silver / silver chloride or potassium chloride is used as the reference electrode;

[0033] 3) After that, the polycarbonate film is assembled in the electroplating tank by electrodepositio...

Embodiment 2

[0036] 1) Using the atomic layer deposition method, the polycarbonate with a pore size of 2 μm is placed in the atomic layer deposition equipment, and at 120 ° C, using diethyl zinc and water as precursors, the pulses are alternately performed for 1200 cycle reactions, and the deposition ZnO;

[0037] 2) Plating a layer of gold on the polycarbonate template containing ZnO with a magnetron ion coating device, the thickness of the metal layer is about 80nm, assembled in the electroplating tank, contacting the gold-plated surface of the polycarbonate film with copper foil, and connecting the electric The chemical workstation is used as the working electrode, the platinum electrode is used as the counter electrode, and the silver / silver chloride or potassium chloride is used as the reference electrode;

[0038] 3) After that, the polycarbonate film is assembled in the electroplating tank by electrodeposition method, and the copper foil is used as the electrical contact of the elec...

Embodiment 3

[0041] 1) Using the method of atomic layer deposition, the polycarbonate with a pore size of 2 μm is placed in the atomic layer deposition equipment, and at 120 ° C, using diethyl zinc and who is the precursor, the pulse is alternately carried out for 1200 cycle reactions, and the deposition ZnO;

[0042] 2) Plating a layer of gold on the polycarbonate template containing ZnO with a magnetron ion coating device, the thickness of the metal layer is about 80nm, assembled in the electroplating tank, contacting the gold-plated surface of the polycarbonate film with copper foil, and connecting the electric The chemical workstation is used as the working electrode, the platinum electrode is used as the counter electrode, and the silver / silver chloride or potassium chloride is used as the reference electrode;

[0043] 3) After that, the polycarbonate film is assembled in the electroplating tank by electrodeposition method, and the copper foil is used as the electrical contact of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com