Method for large-scale preparation of high-efficiency red/near-infrared emission fluorescent carbon dot

A technology for large-scale preparation of fluorescent carbon dots, applied in luminescent materials, chemical instruments and methods, nano-optics, etc., can solve the problems of low efficiency of red carbon dots, limited application of carbon dots, poor environmental stability, etc. Large-scale production, promotion of further application, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for large-scale preparation of high-efficiency red / near-infrared emitting fluorescent carbon dots, which is made of o-phenylenediamine and inorganic metal salt or o-phenylenediamine and dilute hydrochloric acid. The inorganic metal salt in the present invention may also be a crystalline inorganic metal salt.

[0031] The method for large-scale preparation of high-efficiency red / near-infrared emitting fluorescent carbon dots includes the following specific steps: grinding o-phenylenediamine and inorganic metal salt into uniformly granular powder, mixing the two uniformly to obtain a mixed powder; The powder is transferred to the inner lining of the reactor, then packaged, transferred to the drying box, and the reaction temperature and reaction time are set. After the reaction is completed, the temperature of the drying box is cooled to room temperature, and the reactor is taken out to obtain the product; the product is transferred to In the glass cup, the product i...

Embodiment 2

[0042] Grind 1.62g o-phenylenediamine and 0.23g crystalline aluminum chloride into a uniform particle powder, transfer the mixed powder to the inner lining of a 50ml reactor, then encapsulate it, transfer it to a drying box, set the reaction temperature to 200℃ and The reaction time is 12 hours. After the reaction is complete, the temperature of the drying box is cooled to room temperature, and the product is taken out; the product is transferred to a 200ml glass, and the product is washed with deionized water to remove unreacted precursors and certain impurities. After drying, a high-purity solid powder with red carbon dots is obtained. The product was weighed. In this example, 1.57 g of carbon dots were obtained, and the yield reached 85%.

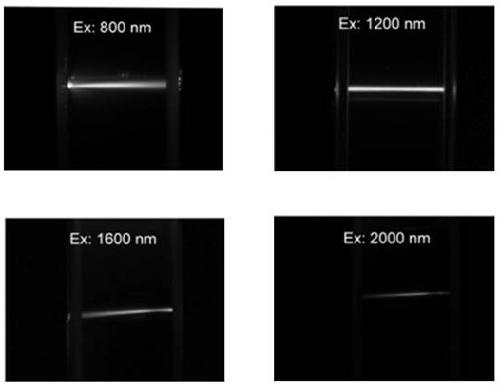

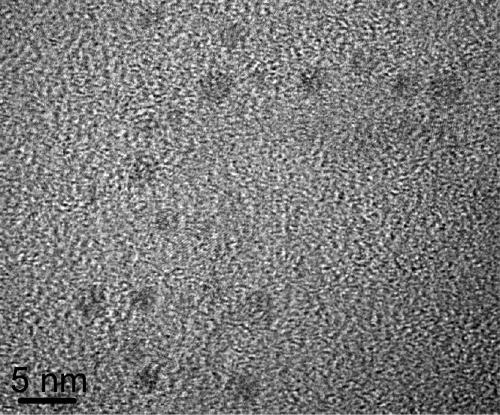

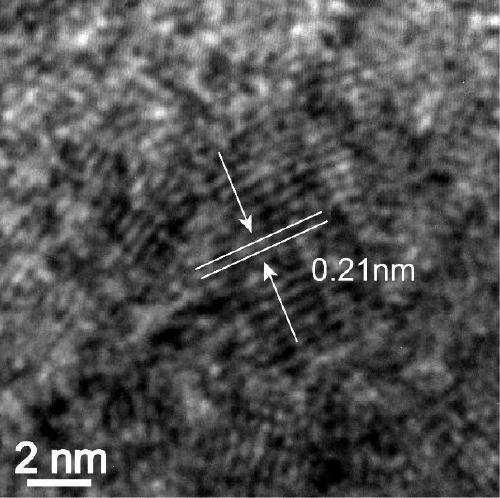

[0043] The above products were tested by transmission electron microscope, red fluorescence, near-infrared fluorescence, four-photon fluorescence, and environmental stability spectroscopy. The results are as follows: Figure 1~6 Shown. Fr...

Embodiment 3

[0045] Grind 1.15g o-phenylenediamine and 0.23g crystalline aluminum chloride into a uniform particle powder, transfer the mixed powder to the inner lining of a 50ml reactor, then encapsulate it, transfer it to a drying box, set the reaction temperature to 180℃ and The reaction time is 10h. After the reaction is completed, the temperature of the drying box is cooled to room temperature, and the reaction kettle is taken out to obtain the product; the product is transferred to a 200ml glass cup, and the product is washed with deionized water to remove unreacted precursors and certain substances. The impurities are then dried to obtain high-purity solid red carbon dot powder. The product was weighed. In this example, 1.15 g of carbon dots were obtained, and the yield reached 83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com