Air cabinet system for decomposing VOCs (volatile organic compounds) by vertical lathe catalyst

A technology of vertical lathe and catalyst, which is applied in the field of VOCs wind cabinet system for decomposing VOCs by vertical lathe catalyst, which can solve the problems of easy saturation of activated carbon, serious light decay of lamp tube, and no adsorption effect, etc. It achieves good effect, simple structure of preparation process and practical effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

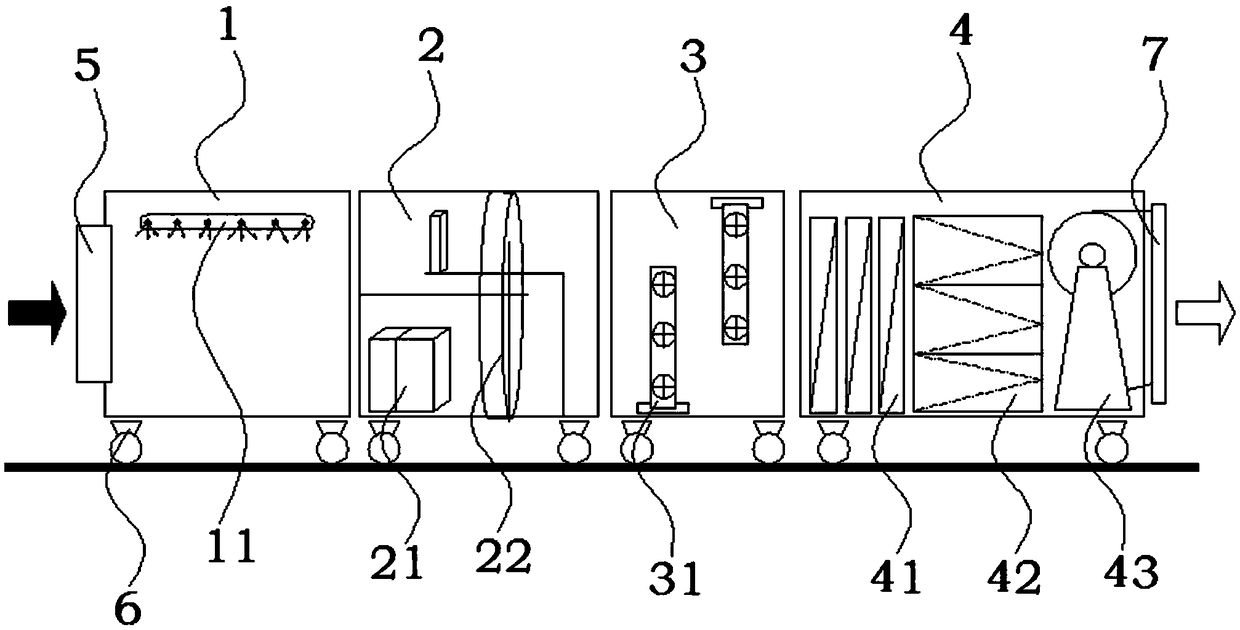

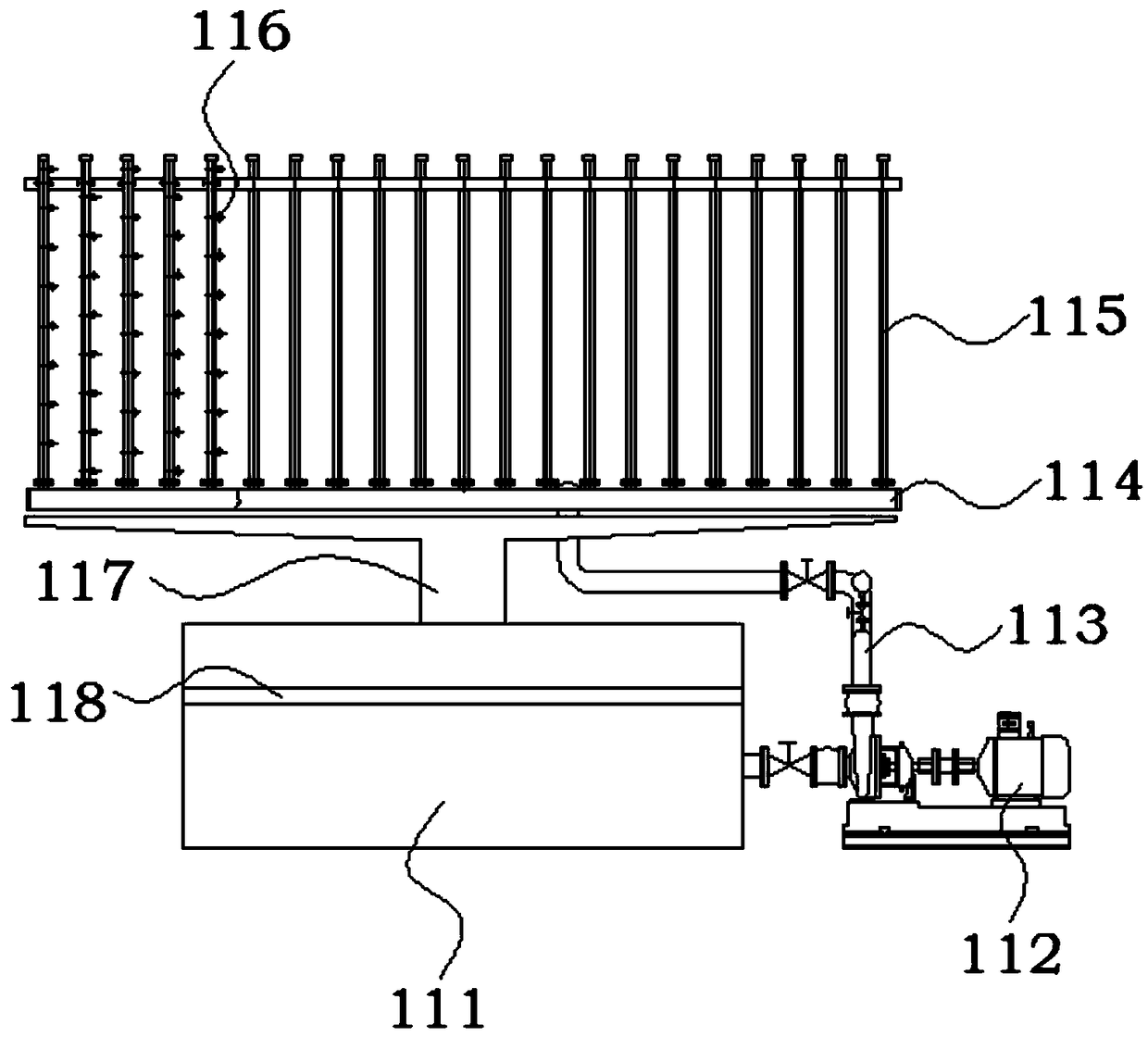

[0028] like Figure 1-4 As shown, the structure of the present invention is: a vertical car catalyst decomposition VOCs wind cabinet system, including water washing and spraying device 1, dehumidification and drying device 2, high-voltage electrostatic device 3, post-processing device 4, rectifying air duct 5 and variable diameter Air duct 7, the front end of the water washing and spraying device 1 is connected to the rectifying air duct 5, and the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com