Preparation method and application of N-doped mesoporous-carbon-loaded metal nano-catalyst

A technology of metal nano and mesoporous carbon, which is applied in the direction of catalytic reaction, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of destroying the structure and composition of active components, increasing the movement tendency of active components, and affecting the service life of catalysts and recycling issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

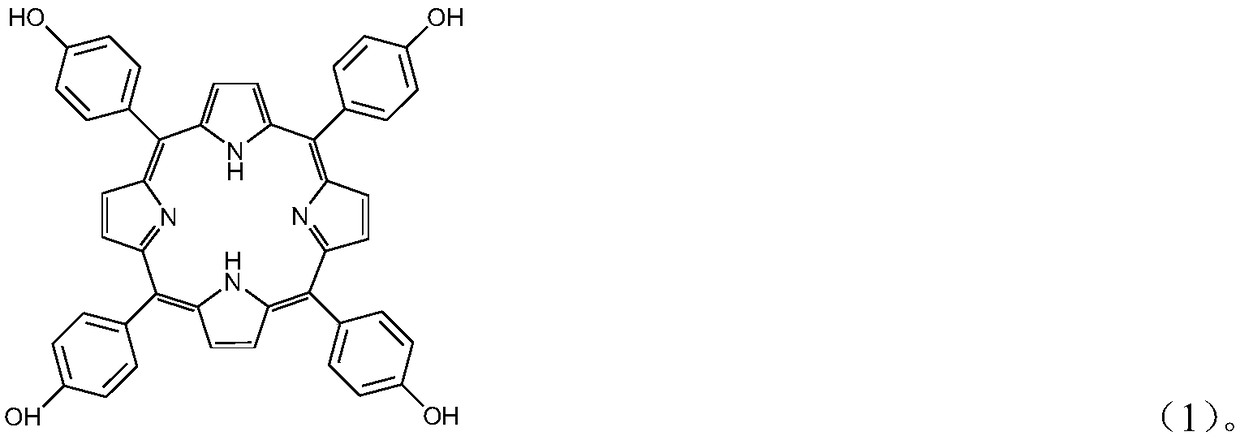

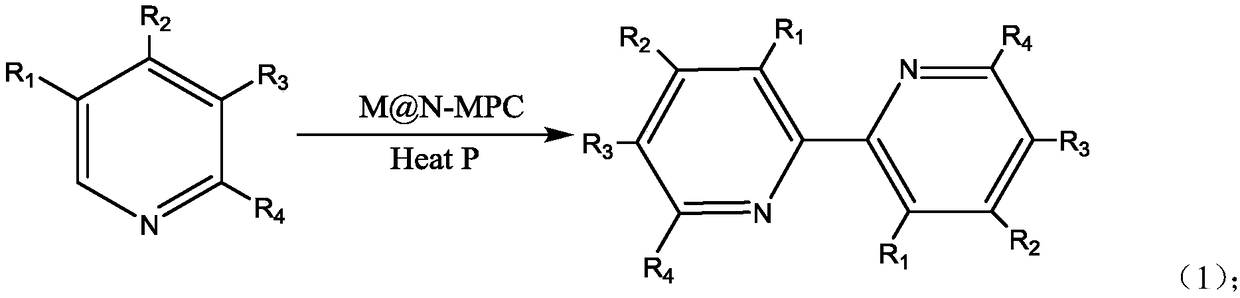

[0038] Example 1: Preparation of Pd@N-MPC and its catalytic bipyridine synthesis

[0039]Get 67.9g of THPP, 5gNaOH and 0.1g of surfactant F127, add it into 100ml of alcohol-water mixed solvent with a volume ratio of 1:1, stir until completely dissolved; add 50ml of formaldehyde solution (37wt%) to the above solution After stirring and mixing evenly, the reaction was continued for 2 hours under heating conditions, and polymer precipitation appeared in the reaction mixture. The above mixture was transferred and sealed into a hydrothermal reactor and placed in a dry oven at 90° C. for 4 h. After the reaction, take out the reactant and adjust the pH of the solution to 6-7 with hydrochloric acid, filter the precipitate and wash it several times with ethanol and distilled water, obtain the covalent organic framework polymer in a 60°C drying oven, and dry it in a vacuum drying oven. The covalent organic framework polymer was pulverized and sieved to obtain a solid with a particle si...

Embodiment 2

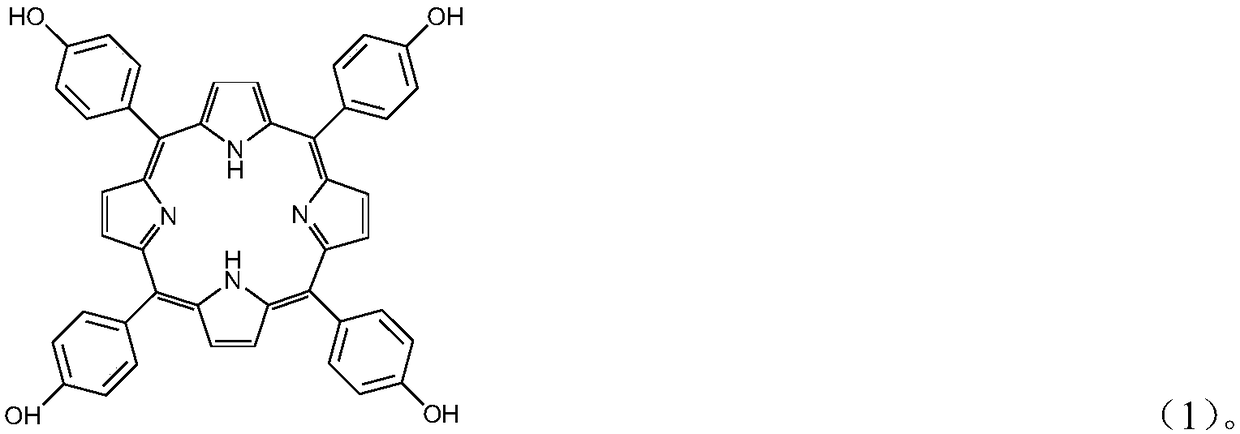

[0041] Example 2: Preparation of Pd@N-MPC and its catalytic bipyridine synthesis

[0042] Get 78.3g of Pd-THPP, 5gNaOH and 0.1g of surfactant F127, join in the 100ml alcohol-water mixed solvent containing volume ratio of 1:1, stir until completely dissolved; add 50ml formaldehyde solution (37wt %), after stirring and mixing evenly, the reaction was continued for 2 hours under heating conditions, and polymer precipitation occurred in the reaction mixture. The above mixture was transferred and sealed into a hydrothermal reactor and placed in a dry oven at 90° C. for 4 h. After the reaction, take out the reactant and adjust the pH of the solution to 6-7 with hydrochloric acid, filter the obtained precipitate, wash it several times with ethanol and distilled water, and dry it in a vacuum oven at 60°C to form a metal-coordinated organic framework polymer precursor. 10 g of the precursor was placed in a vacuum tube furnace, and carbonized and reduced at high temperature in a mixed ...

Embodiment 3

[0044] Example 3: Preparation of Pt@N-MPC and its catalytic bipyridine synthesis

[0045] Get 67.9g of THPP, 5gNaOH and 0.1g of surfactant F127, add it into 100ml of alcohol-water mixed solvent with a volume ratio of 1:1, stir until completely dissolved; add 50ml of formaldehyde solution (37wt%) to the above solution After stirring and mixing evenly, the reaction was continued for 2 hours under heating conditions, and polymer precipitation appeared in the reaction mixture. The above mixture was transferred and sealed into a hydrothermal reactor and placed in a dry oven at 90° C. for 4 h. After the reaction, take out the reactant and adjust the pH of the solution to 6-7 with hydrochloric acid, filter the precipitate and wash it several times with ethanol and distilled water, obtain the covalent organic framework polymer in a 60°C drying oven, and dry it in a vacuum drying oven. The covalent organic framework polymer was pulverized and sieved to obtain a solid with a particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com