Preparation method of catalyst for effectively converting furfural into 2-methylfuran

A methylfuran catalyst, a catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor catalyst stability, achieve stable performance, Highly active and selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

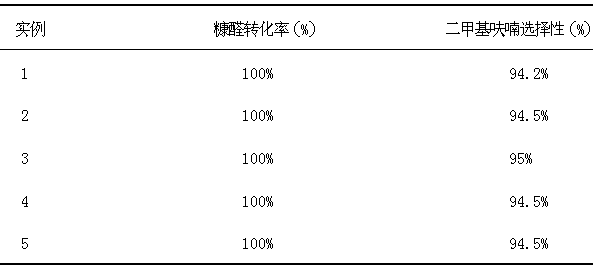

Examples

Embodiment 1

[0029] Example 1 25.6 g of copper nitrate trihydrate was dissolved in 100 ml of deionized water, and then added to 250 ml of silica sol. Dissolve 32 grams of ammonium carbonate in 200ml of deionized water, then add the ammonium carbonate solution to the metal salt solution, and transfer it to a hydrothermal reaction kettle, react at 100°C for 4 hours, and then carry out distillation until the pH is 7 , and then filtered and washed, dried at 110°C for 12 hours, and then calcined at 400°C for 4 hours in a muffle furnace to prepare the catalyst.

Embodiment 2

[0030] Example 2 32 grams of copper nitrate trihydrate and 8.36 grams of barium nitrate were dissolved in 100 ml of deionized water, and then added to 250 ml of silica sol. Take 36 grams of urea and dissolve it in 100ml deionized water, mix the two solutions under stirring conditions, and transfer them to a hydrothermal reaction kettle, react at 100°C for 4 hours, then carry out distillation reaction until the pH is 7, and then After filtering and washing, it was dried at 110°C for 12 hours, and then calcined at 450°C for 4 hours in a muffle furnace to prepare the catalyst.

Embodiment 3

[0031] Example 3 Dissolve 32 grams of copper nitrate trihydrate in 150 ml of water and ethanol solution, H 2 O: C 2 h 5 OH=2, then added to 250ml silica sol. Take 36 grams of urea and dissolve it in 100ml deionized water, mix the two solutions under stirring conditions, and transfer them to a hydrothermal reaction kettle, react at 100°C for 4 hours, then carry out distillation reaction until the pH is 7, and then After filtering and washing, it was dried at 110°C for 12 hours, and then calcined at 450°C for 4 hours in a muffle furnace to prepare the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com