In situ and real time quality control in additive manufactu process

An additive manufacturing and process technology, applied in the field of in-situ and real-time quality control in the additive manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

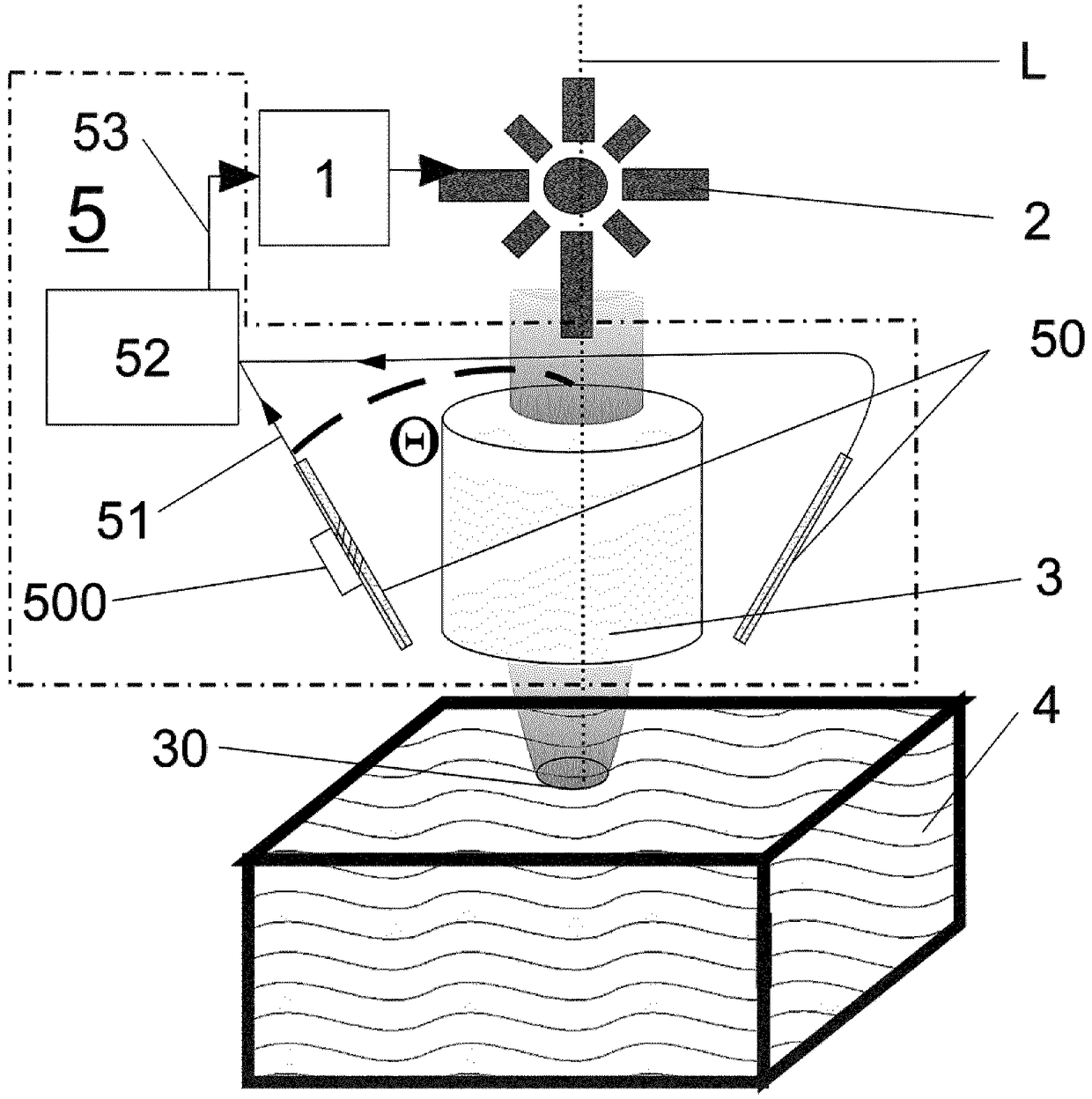

[0033] The purpose of the present invention is to introduce a novel method for quality control of additive manufacturing (AM) processes, in particular based on ion beam, microwave or laser powder sintering or melting (for powder bed and ion and electron beam, microwave or laser powder deposition). The method is intended to be an independent feedback control loop, providing real-time online monitoring of the additive manufacturing process. Furthermore, an apparatus using the method is disclosed.

[0034] Additive manufacturing device including ion and electron beam, microwave or laser irradiation system, ion and electron beam, microwave or laser irradiation system including ion and electron beam, microwave or laser electronic device 1 controlled ion and electron beam, microwave or laser source 2 , ion and electron beam, microwave or laser focusing device 3, ion and electron beam, microwave or laser focusing device 3 irradiates ion and electron beam, microwave or laser source 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com