SNCrW stainless steel metallographic etching liquid, preparation method thereof and using method thereof

A preparation method and technology of corrosion solution, which is applied in the field of corrosion solution, can solve problems such as poor corrosion reproducibility, poor control of corrosion time, and easy over-corrosion, etc., to achieve clear metallographic structure and grain boundaries, and to meet accurate ratings and well-controlled effects at grain size levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、 Embodiment 3 and Embodiment 3

[0037] Implementation 1, embodiment 3 and embodiment 3 use corrosion solution method as follows:

[0038] When using a corrosive solution, first sample the SNCrW (3Cr20Ni10W2) stainless steel after solid solution, and cut it into a metallographic sample of 10mm×20mm×10mm with a cutting machine; Chamfer and grind the inspection surface to avoid scratching the polishing cloth during subsequent polishing; use 320# sandpaper to conduct metallographic rough grinding on the metallographic sample, and then use 800#, 1000#, 1500# metallographic water sandpaper for metallographic test Then use 2.5μm diamond abrasive paste to grind and polish the metallographic sample on the polishing machine. After grinding and polishing for 2 minutes, when it is observed that the polished surface of the metallographic sample is bright without any scratches, replace it with a clean one. Felt polishing cloth, use distilled water as a lubricant, and polish for 1min; rinse the grinding and polishing surfa...

Embodiment 1

[0040] The composition of the corrosion solution: 90mL of water, 15mL of concentrated hydrochloric acid, 5g of ferric sulfate, wherein the concentration of concentrated hydrochloric acid is 36% to 38%, and the water is distilled water;

[0041] When preparing the corrosion solution, first use an electronic balance to weigh 5g of ferric sulfate and put it into a 250mL beaker, then use a measuring cylinder to measure 90mL of water and pour it into the beaker, then measure 15mL of concentrated hydrochloric acid into the beaker, stir with a glass rod until the sulfuric acid After the iron is completely dissolved, let it stand for at least 2 minutes;

[0042] When using corrosive liquid, the metallographic sample corrosion time reaches 5min.

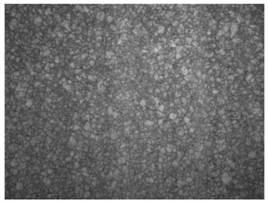

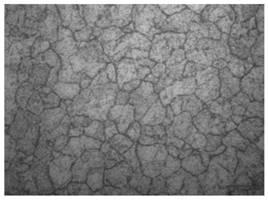

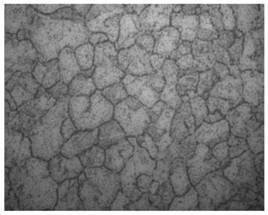

[0043] From figure 1 , figure 2 It can be seen that the SNCrW (3Cr20Ni10W2) stainless steel metallographic corrosion solution has a very good corrosion effect. When it is used to corrode metallographic samples, the structure of the metallo...

Embodiment 2

[0045] The composition of the corrosion solution: 89mL of water, 16mL of concentrated hydrochloric acid, 6g of ferric sulfate, wherein the concentration of concentrated hydrochloric acid is 36% to 38%, and the water is distilled water;

[0046] When preparing the corrosion solution, first weigh 6g of ferric sulfate with an electronic balance and put it into a 250mL beaker, then use a measuring cylinder to measure 89mL of water and pour it into the beaker, then measure 16mL of concentrated hydrochloric acid into the beaker, stir with a glass rod until the sulfuric acid After the iron is completely dissolved, let it stand for at least 2 minutes;

[0047] When using corrosive liquid, the metallographic sample corrosion time reaches 6min.

[0048] From image 3 , Figure 4 It can be seen that the SNCrW (3Cr20Ni10W2) stainless steel metallographic corrosion solution has a very good corrosion effect. When it is used to corrode metallographic samples, the structure of the metallograp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com