PET material for beverage bottle caps

A bottle cap and beverage technology, applied in the field of plastics, can solve problems such as long production cycle, limited use of polyethylene terephthalate, and difficulty in molding and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

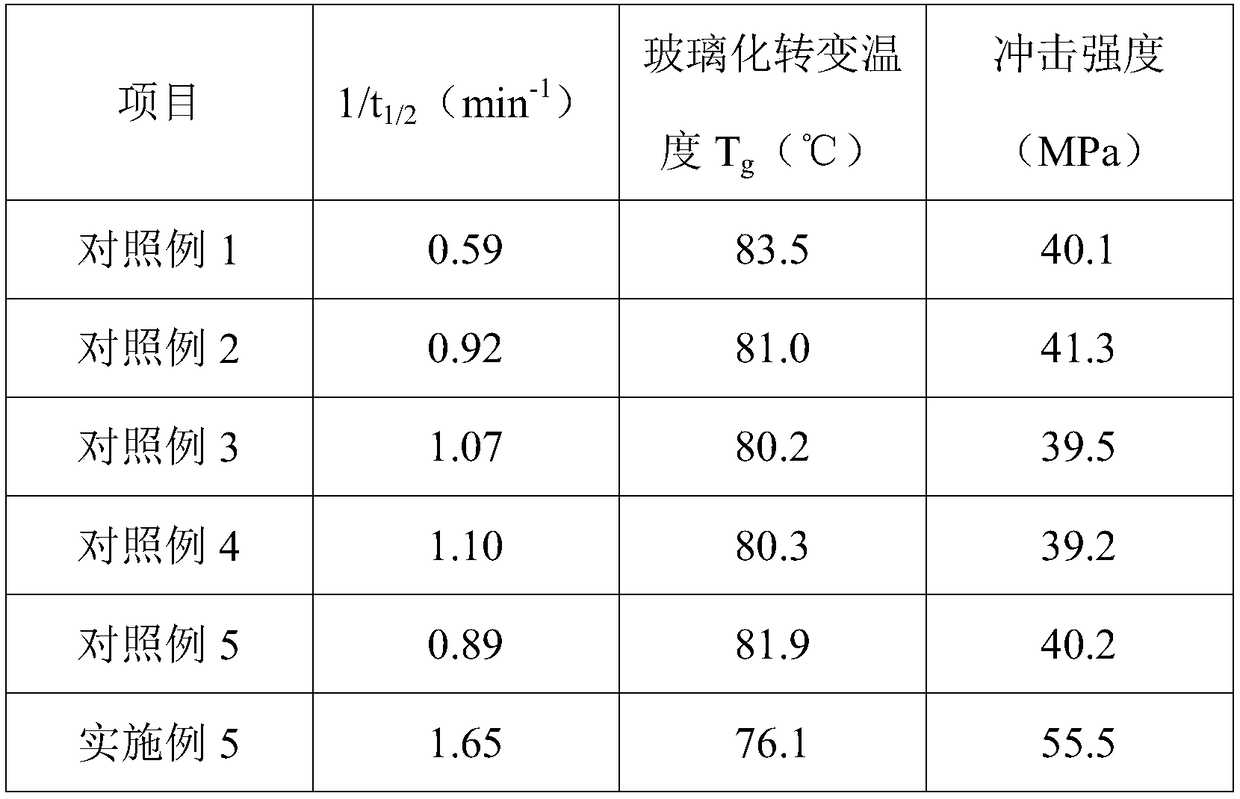

Examples

Embodiment 1

[0018] A PET material for beverage bottle caps, its raw materials include by weight: 80 parts of polyethylene terephthalate, 15 parts of POE resin, 25 parts of filler, 0.07 parts of antioxidant, 3 parts of compatibilizer, the composition 2 parts of nucleating agent, 1.2 parts of plasticizer, 2 parts of lubricant;

[0019] Wherein, the nucleating agent is hydrotalcite, magnesium carbonate, sodium benzoate, PEG4000.

Embodiment 2

[0021] A PET material for beverage bottle caps, its raw materials include by weight: 70 parts of polyethylene terephthalate, 20 parts of POE resin, 20 parts of filler, 0.1 part of antioxidant, maleic anhydride graft compatible 2 parts of agent, 3 parts of nucleating agent, 1 part of tributyl citrate, 3 parts of lubricant;

[0022] Wherein, the nucleating agent is hydrotalcite, magnesium carbonate, sodium benzoate, PEG4000, wherein, the weight ratio of hydrotalcite, magnesium carbonate, sodium benzoate, PEG4000 is 1:1:1:1;

[0023] The filler is glass fiber, kaolin and polytetrafluoroethylene superfine powder, wherein the weight ratio of glass fiber, kaolin and polytetrafluoroethylene superfine powder is 0.5:15:3.

Embodiment 3

[0025] A PET material for beverage bottle caps, its raw materials include by weight: 90 parts of polyethylene terephthalate, 10 parts of POE resin, 30 parts of filler, 0.05 part of antioxidant, maleic anhydride graft compatible 4 parts of agent, 1 part of nucleating agent, 1.5 parts of tributyl citrate, 1 part of lubricant;

[0026] Wherein, the nucleating agent is hydrotalcite, magnesium carbonate, sodium benzoate, PEG4000, wherein, the weight ratio of hydrotalcite, magnesium carbonate, sodium benzoate, PEG4000 is 2:0.5:1.5:0.5;

[0027] The filler is glass fiber, kaolin, and polytetrafluoroethylene ultrafine powder, wherein the weight ratio of glass fiber, kaolin, and polytetrafluoroethylene ultrafine powder is 1:10:5;

[0028] The lubricant is white oil and stearic acid, wherein the weight ratio of white oil and stearic acid is 1:0.5;

[0029] The antioxidants are antioxidant 1010 and antioxidant BHT.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com