Carbonic acid rare earth roasting method

A rare earth carbonate and roasting technology, applied in the field of metallurgy, can solve the problems of high energy consumption, low production efficiency, uneven heat source, etc., and achieve the effect of reducing manual operation, improving production efficiency and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

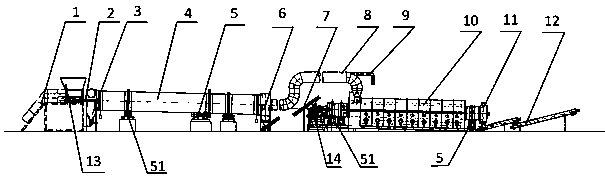

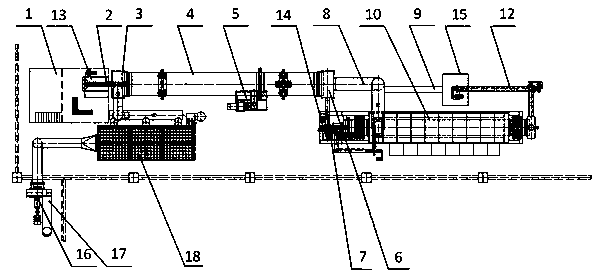

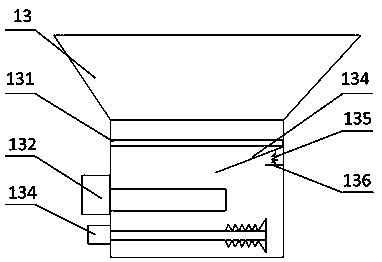

[0047] Such as Figure 1-5 As shown, a roasting method of rare earth carbonate is roasted using a roasting system, which includes a steel loading platform 1, a first screw feeder 2, a first cyclone separator 3, a pulse bag filter 18, a drying rotary Kiln 4, second cyclone separator 6, tail gas induced draft fan 16, emptying pipe 17, second screw feeder 7, pipe fittings, screw feeder 14, ventilation pipe 8, roasting device 10 and jacketed water-cooled conveyor 12; The first screw feeder 2 is set above the loading steel platform 1; the top of the first screw feeder 2 is provided with a material inlet 13; the first screw feeder 2 is set at the first cyclone separation The side of the device 3; the drying rotary kiln 4 is located between the first cyclone separator 3 and the second cyclone separator 6; the bottom of the first cyclone separator 3 is connected to the pulse bag filter 18; the The pulse bag filter 18 is connected with the tail gas induced draft fan 16 and the emptyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com