Ethyl acetate-producing saccharomycete and application thereof

A technology of ethyl acetate and yeast, applied in fermentation, preparation of alcoholic beverages, methods based on microorganisms, etc., can solve the problems of insufficient fragrance, insufficient quality of finished wine, low content of esters, etc., and achieve good alcohol content. and the effect of temperature tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Screening of strains

[0050] 1. Primary screening of strains

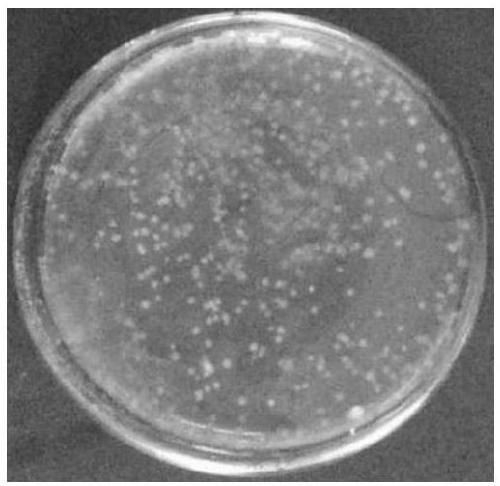

[0051] Grind the solid-state fermented Fen-flavor liquor fermented grains, take 10g each and put them into the Erlenmeyer flask, add 100mL of the enriched culture solution, shake the shaker for 1 hour, dilute the enriched culture solution with sterile water to 10 -6 、10 -7 、10 -8 times, respectively coated the primary screening plate, and placed in a constant temperature incubator, cultured at 28°C for 72 hours, and observed the culture results regularly every 6 hours. Observe the strains with color-changing circles, distinguish different strains according to the colony shape and combined with the results of microscopic examination, purify with the method of plate streaking, and select 30 strains with yellow color-changing circles, the original numbers are Jm-01, Jm-02, until Jm30. It was observed that, as figure 1 and figure 2 As shown, the yeast grows on the surface of the primary screening solid med...

Embodiment 2

[0072] Identification of target strains

[0073] 1. Morphological identification

[0074] Through the colony characteristics of the target bacterial strain Jmx-01 and the observation under a 40-fold microscope, such as image 3 and Figure 4 As shown, the shape of Jmx-01 is oval as shown in the figure, and the buds formed by budding can be seen. The single colony is round, with bulges, milky white, neat edges, easy to pick, sticky, with yeast Typical morphological characteristics of bacterial colonies.

[0075] 2. Molecular biological identification

[0076] Biodiversity Sequencing of Jmx-01 Strain Using 18S rDNA Method

[0077] a. Pick a single colony of yeast and inoculate it in 5 mL of YEPD medium, culture at 220 rpm, 30°C for 12-16 hours on a shaker;

[0078] b. Centrifuge at 5000g for 5min, wash once with 1mL sterile water, add 200ul of glass beads, add 200ul of bacteriostasis buffer and 200uL of phenol chloroform, vortex for 1min, place on ice for 1min, repeat 4 tim...

Embodiment 3

[0096] Application of Yeast Jmx-01 in Production of Ethyl Acetate

[0097] a. Configure a culture system containing acetic acid and ethanol, wherein the volume percentage of acetic acid is 1%-5%, and the volume percentage of ethanol is 20%-60%. The preferred condition is that the volume percentage of acetic acid is 1 %, the volume percentage of ethanol is 20%,

[0098] b. Strain Jmx-01 was inoculated in YEPD liquid medium, cultured with shaking at 28°C and 220rpm, and added the yeast supernatant of 2 days into the acetic acid and ethanol culture system configured in step a according to the ratio of 4:1, and mixed well , placed at 26-32°C, the preferred temperature is set at 30°C, shaker at 200rpm, and fermented for 48h;

[0099] c. Determination of ethyl acetate content in the reaction system by gas chromatography (National Bureau of Quality Supervision, Inspection and Quarantine of the People's Republic of China. GB / T10345-2007, Liquor Analysis Methods [S]. Beijing: China St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com