Method for preparing ethylene 2-(methacryloyloxy)ethyl phosphate

A technology of methacryloyloxy and hydroxyethyl methacrylate, which is applied in the field of compound preparation, can solve the problems of affecting product quality, the reaction is not easy to be completed, and the reaction takes a long time, and achieves colorless and transparent high purity, fast reaction, and production The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

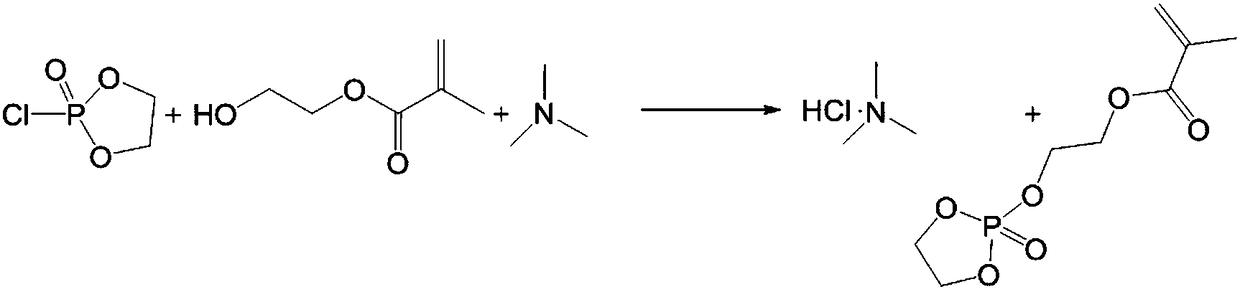

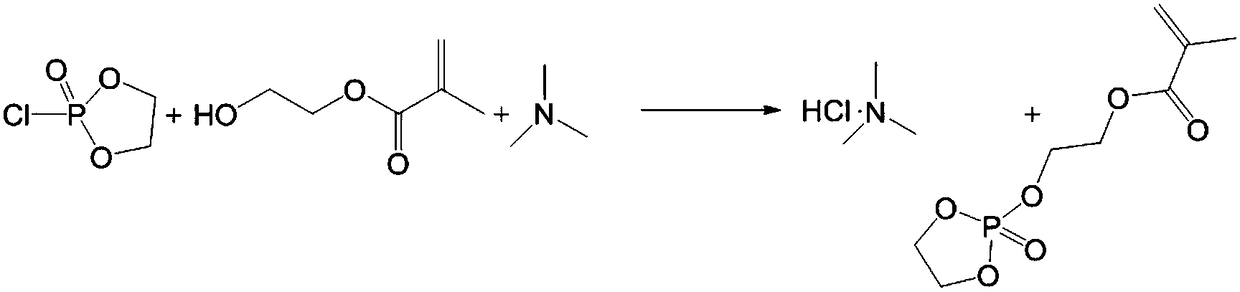

Method used

Image

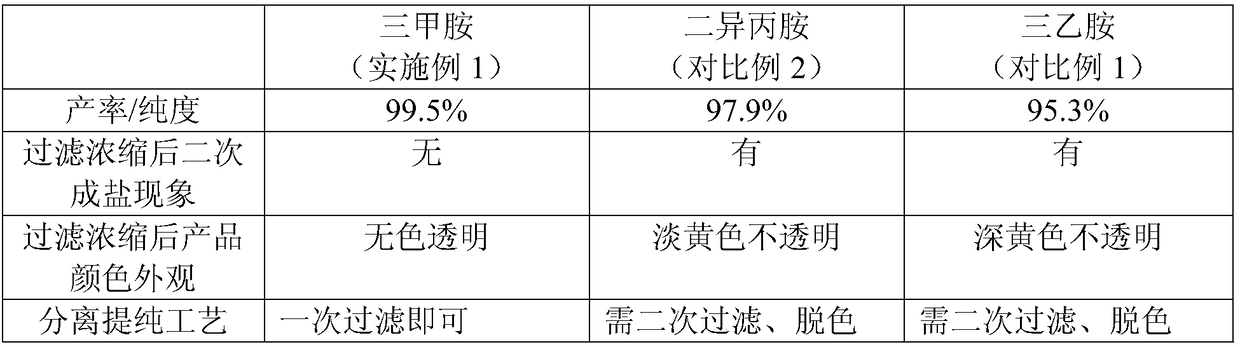

Examples

Embodiment 1

[0037] 1 mole (142.4 grams) of 2-chloro-2-oxo-1,3,2-dioxaphospholane and 500 grams of ethyl acetate were introduced into the synthesis kettle to configure 2-chloro-2-oxo-1, 3,2-dioxaphospholane solution; 1 mole (130.1 grams) of hydroxyethyl methacrylate was added to the synthesis kettle, and stirred evenly; 320 grams of ethyl acetate was added to the frozen addition kettle, and the liquid temperature was controlled at - At 5°C, introduce 1.05 moles (62 grams) of trimethylamine gas. At this time, trimethylamine gas (boiling point: 3-4°C) has a high solubility in frozen ethyl acetate, so that trimethylamine can be dissolved in ethyl acetate to form liquefaction Trimethylamine solution; open the valve of the frozen feeding kettle and add it dropwise to the synthesis kettle. The reaction temperature is maintained at (-5~0°C) by the high and low temperature integrated machine. After the dropwise addition, stop freezing and raise the temperature to (15~25°C) to continue Stir for 60 ...

Embodiment 2

[0039] 10 moles (1424 grams) of 2-chloro-2-oxo-1,3,2-dioxaphospholane and 5000 grams of ethyl acetate were introduced into the synthesis kettle to configure 2-chloro-2-oxo-1, 3,2-dioxaphospholane solution; 1 mole (1301 grams) of hydroxyethyl methacrylate was added to the synthesis kettle, and stirred evenly; 3200 grams of ethyl acetate was added to the frozen feeding kettle, and the liquid temperature was controlled at - At 5°C, introduce 10.5 moles (621 grams) of trimethylamine gas. At this time, using the characteristics of high solubility of trimethylamine gas (boiling point 3-4°C) in frozen ethyl acetate, trimethylamine is dissolved in ethyl acetate to form liquefaction Trimethylamine solution; open the valve of the frozen feeding kettle and add it dropwise to the synthesis kettle. The reaction temperature is maintained at (-5~0°C) by the high and low temperature integrated machine. After the dropwise addition, stop freezing and raise the temperature to (15~25°C) to continu...

Embodiment 3

[0041]1 mole (142.4 grams) of 2-chloro-2-oxo-1,3,2-dioxaphospholane and 500 grams of ethyl acetate were introduced into the synthesis kettle to configure 2-chloro-2-oxo-1, 3,2-dioxaphospholane solution; add 1 mole (130.1 grams) of hydroxyethyl methacrylate into the synthesis kettle, stir evenly, control the liquid temperature at -5°C, and slowly introduce 1.05 moles (62 g) trimethylamine gas, the reaction temperature is maintained at (-5~0°C) by the high and low temperature integrated machine, after the introduction is completed, stop freezing, raise the temperature to (15~25°C) and continue stirring for 60 minutes; the trimethylamine salt formed after the reaction is completed The acid salt is removed by filtration through a filter device to obtain a colorless and transparent mother liquor; the mother liquor is introduced into a concentrated vacuum distillation device, and ethyl acetate is distilled off to obtain a colorless and transparent viscous product. Sampling Analysis,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com