Composite film with high impact resistance

A technology of high impact resistance and composite film, which is applied in the direction of flexible coverings, synthetic resin layered products, types of packaging items, etc., and can solve problems such as broken bags and poor impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

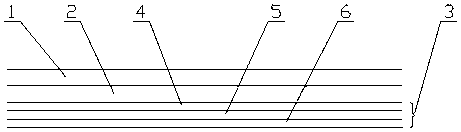

[0009] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: a composite film with high impact resistance. The composite film has a three-layer structure. From top to bottom, there are printing layer 1, adhesive layer 2 and PE layer 3. The printing layer 1 is a cast nylon layer. , the adhesive layer 2 is a two-component polyurethane adhesive layer, preferably an aliphatic adhesive layer;

[0010] The PE layer 3 is also a three-layer structure, from top to bottom are the first composite PE layer 4, the second composite PE layer 5 and the third composite PE layer 6, the first composite PE layer 4 is made of LLDPE and elastic body composition, and the elastomer accounts for more than 10% of the total mass of the first composite PE layer 4, the second composite PE layer 5 is composed of LLDPE and LDPE of equal mass, and the third composite PE layer 6 is composed of the same Quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com