Ultrahigh-frequency electromagnetic wave shielding film without chemical electroplating process and conductive particles, and manufacturing method of circuit board comprising film

A technology of ultra-high frequency electromagnetic waves and conductive particles, applied in chemical instruments and methods, magnetic field/electric field shielding, printed circuit components, etc., can solve the problems of relatively high size requirements of conductive particles, inability to pierce the shielding film, and affecting grounding, etc. , to achieve the effect of improving the overall shielding effect, saving production time, and improving barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

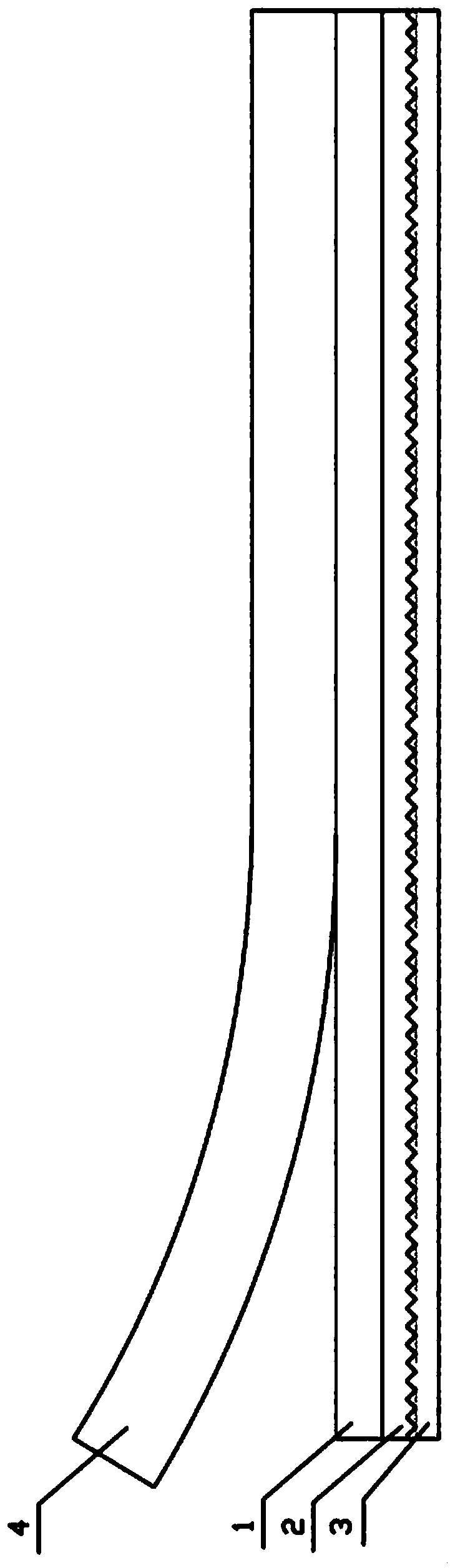

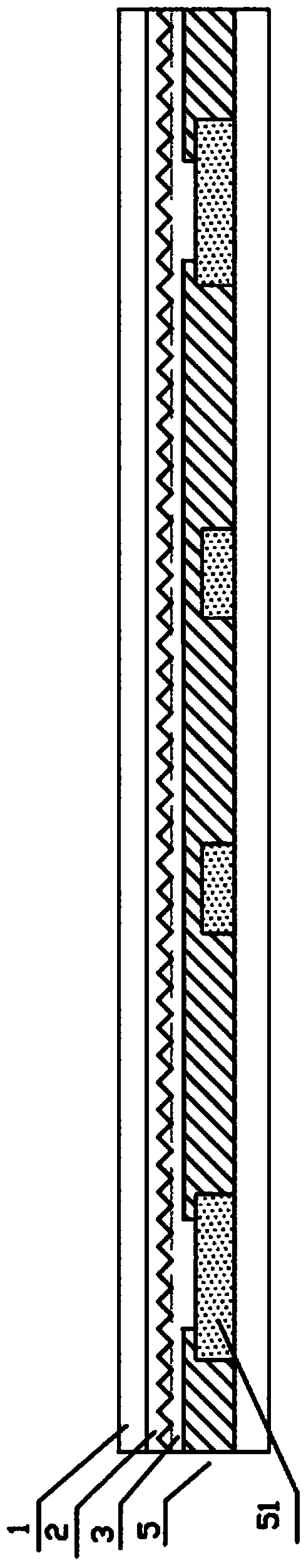

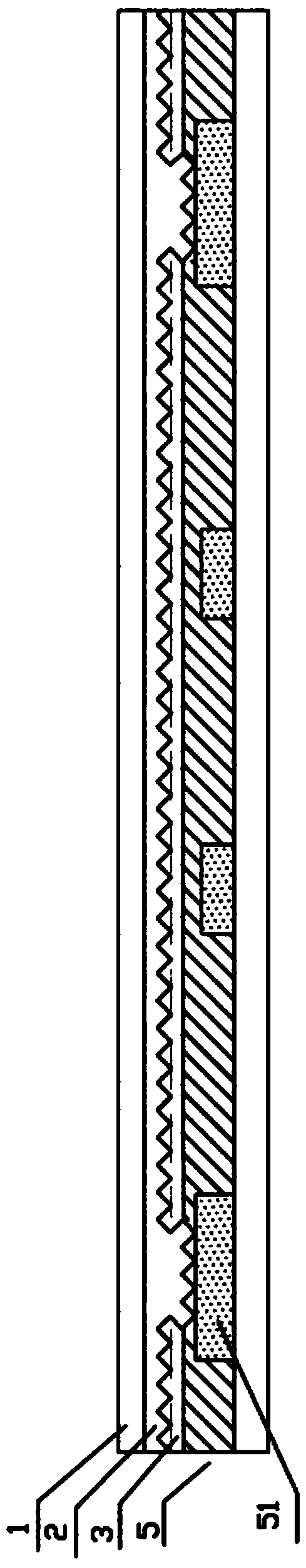

[0053] Such as figure 1 As shown, an electromagnetic wave shielding film for printed circuit boards, the carrier film 4 is provided with a special treatment roughened insulating layer 1, the specially treated roughened insulating layer 1 is provided with an alloy shielding layer 2, and the alloy shielding layer 2 is provided with a pure Adhesive film layer 3, wherein the carrier film is a PET release film, which can be peeled off from the specially treated roughened insulating layer 1.

[0054] The manufacturing method of the electromagnetic wave shielding film comprises the following steps:

[0055] 1) Form a specially treated roughened insulating layer on the carrier film 4: select a PET release film with a thickness of 25 to 150 microns and a width of 100 mm to 1000 mm, apply ink on the release surface side, and form after it is completely cured Roughen the insulation layer 1 by special treatment, the ink is epoxy resin ink or polyurethane ink, with a thickness of 1-25 mic...

Embodiment 2

[0061] Such as figure 1 As shown in the electromagnetic wave shielding film, the carrier film layer 4 is provided with a specially treated roughened insulating layer 1, the specially treated roughened insulating layer 1 is provided with an alloy shielding layer 2, and the alloy shielding layer 2 is provided with a pure rubber film layer 3. Wherein, the carrier film is a PET release film, which can be peeled off with the specially treated roughened insulating layer 1 .

[0062] The manufacturing method of the electromagnetic wave shielding film comprises the following steps:

[0063] 1) Form a specially treated roughened insulating layer on the carrier film layer 4: Select a PET release film with a thickness of 25-150 microns and a width of 100 mm to 1000 mm, and apply ink on the release surface side, and after it is completely cured Forming a specially treated roughened insulating layer 1, the ink is epoxy resin ink or polyurethane ink, with a thickness of 1-25 microns, prefe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com