Flanging machine

An edge folding machine and edge trimming technology, applied in the field of edge folding machines, can solve the problems of slowing down the production speed of battery products, unguaranteed safety, and reducing the quality of battery production, so as to save manpower, high transport stability, Good flattening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

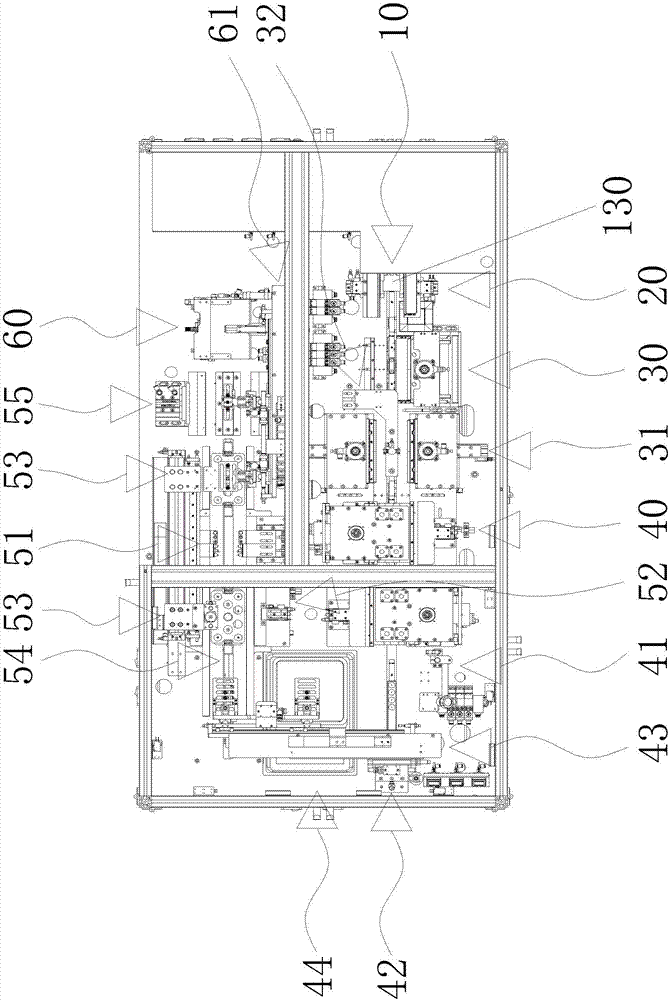

[0046] refer to Figure 1 ~ Figure 2 As shown, the invention discloses an edge folding machine, which includes a frame 1 , a base 2 and a cover 3 . Rack 1 is used for electrical control and human-computer interaction. The base 2 is arranged on the frame 1 and is used to carry various functional mechanisms. The casing 3 is enclosed above the base 2, and is used to protect the internal mechanism and prevent personal injury caused by the internal mechanism; the casing 3 has a transparent window for observing the internal operation conditions.

[0047] The above-mentioned base 2 is provided with an edge trimming transfer mechanism 10 for transferring the battery 130, a centering mechanism 20 for finding the center line of the battery 130, an edge trimming mechanism for cutting excess plastic film, an edge trimming pressing mechanism 32, and a bending plastic sealing mechanism. Film folding mechanism 40, code scanning mechanism 41 for determining the identity of the battery 130, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com