Graphene composite fiber yarn, preparation method and application thereof

A graphene composite and graphene technology, applied in the textile field, can solve the problems of graphene structure and performance adverse effects, easy agglomeration, limited application, etc., to achieve good spinnability and continuity, complete crystal structure, and spinnability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

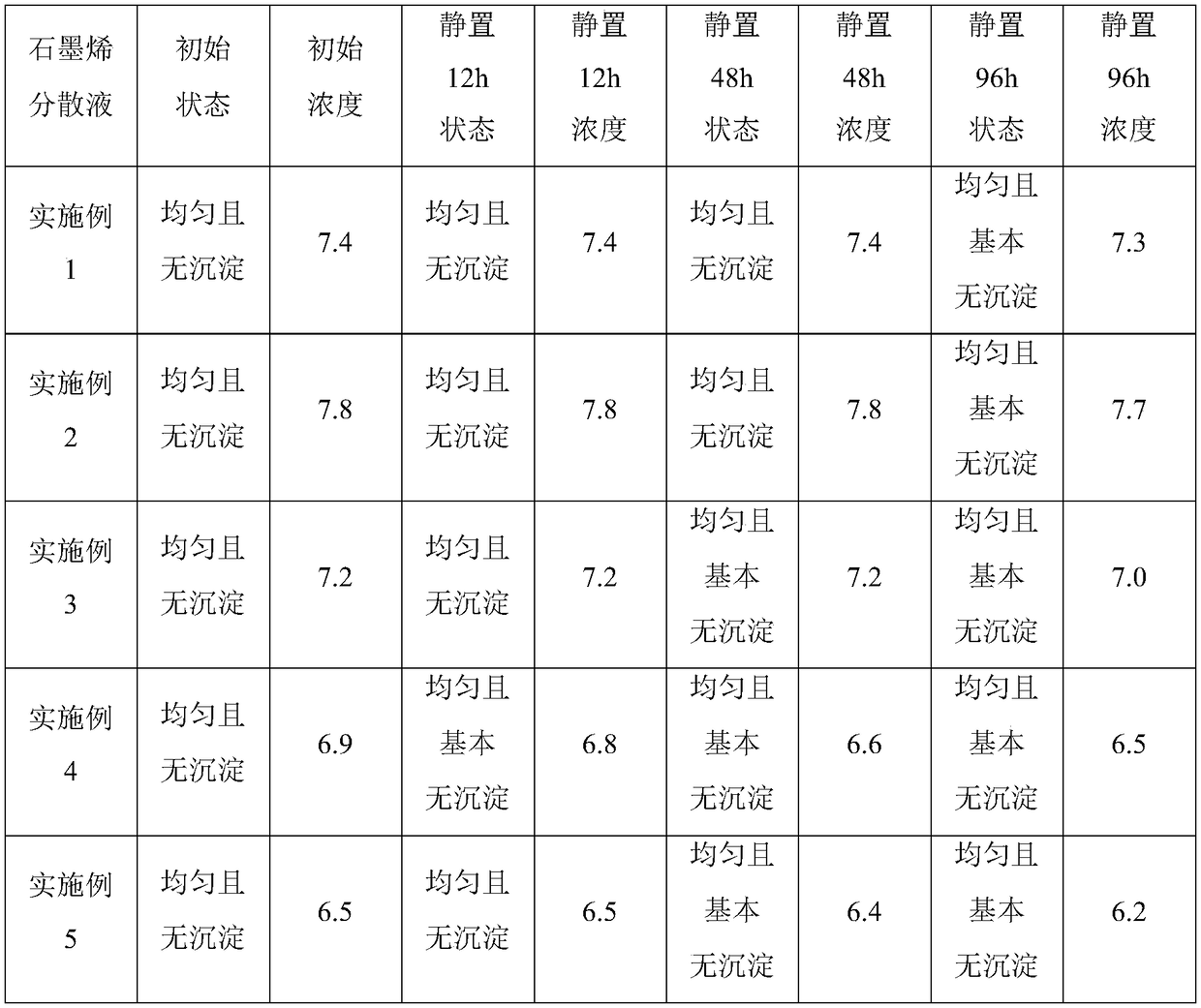

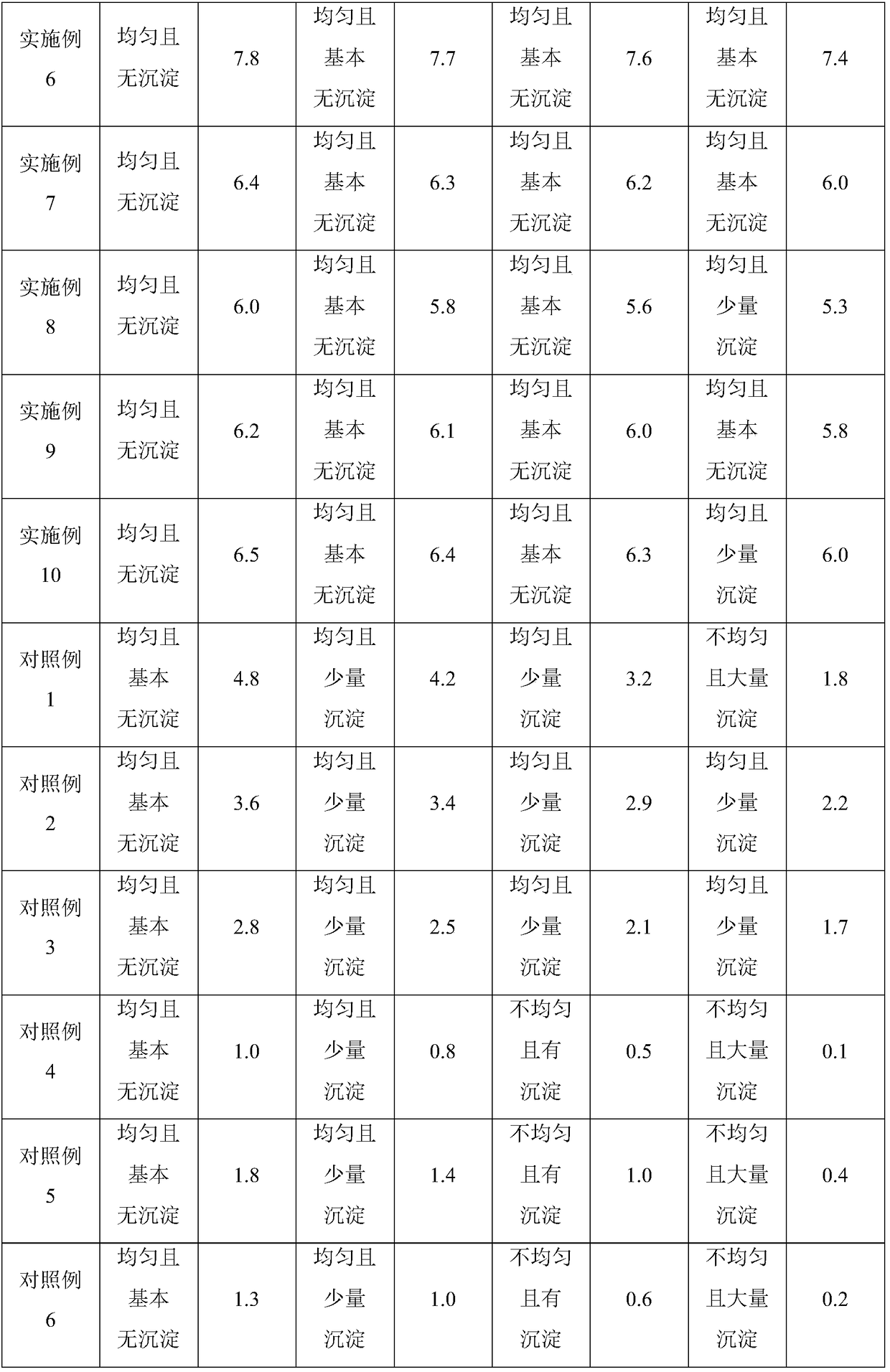

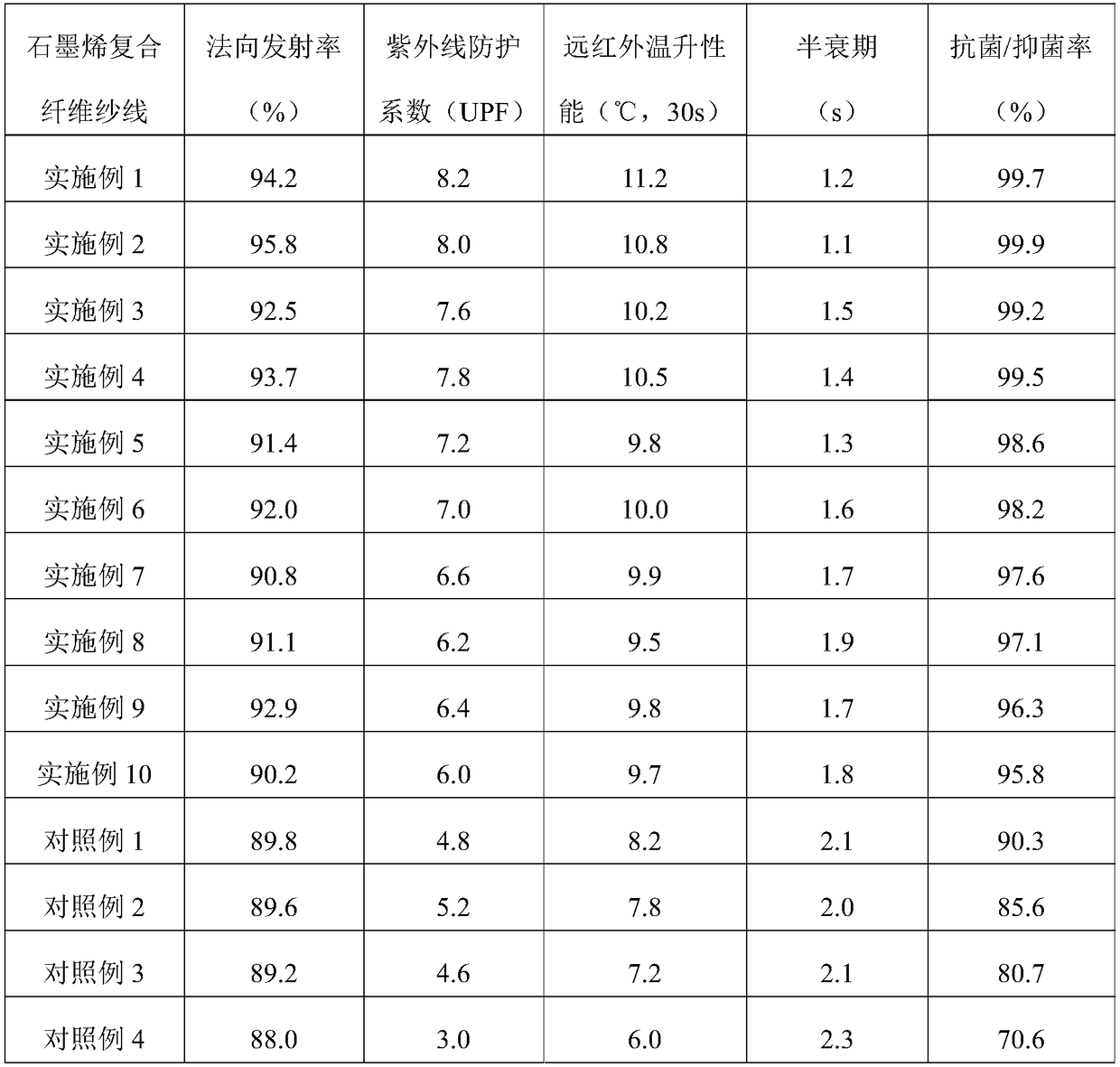

Examples

Embodiment 1

[0049] 1. Preparation of graphene dispersion

[0050] Put non-oxidized graphene (number of layers is 1-9 layers, average particle size ≤ 2 μm, hereinafter referred to as graphene) in deionized water, and then add carboxymethyl cellulose sodium for ultrasonic dispersion, wherein: graphene and carboxy The mass ratio of methylcellulose sodium is 15:1; the ultrasonic dispersion is carried out twice, the frequency of the first ultrasonic dispersion is 80kHZ, and the dispersion time is 1h. The frequency of the second ultrasonic dispersion is 50kHZ, and the dispersion time is 2h to obtain the first dispersion liquid.

[0051] Add hexamethylenetetramine to the above-mentioned first dispersion liquid, stir and reflux reaction; wherein, the mass ratio of graphene and hexamethylenetetramine is 6:1, the temperature of stirring and reflux reaction is 100°C, and the time is 2h, the second dispersion liquid was prepared.

[0052] The above-mentioned second dispersion is centrifuged, wherei...

Embodiment 2

[0066] 1. Preparation of graphene dispersion

[0067] Put non-oxidized graphene (the number of layers is 1-9 layers, the particle size is 100nm-2μm) in deionized water, and then add sodium carboxymethyl cellulose for ultrasonic dispersion, wherein: graphene and sodium carboxymethyl cellulose The mass ratio is 20:1; the ultrasonic dispersion is carried out twice, the frequency of the first ultrasonic dispersion is 100kHZ, and the dispersion time is 0.5h. The frequency of the second ultrasonic dispersion is 60kHZ, and the dispersion time is 1.5h to obtain the first dispersion liquid.

[0068] Add hexamethylenetetramine to the above-mentioned first dispersion liquid, stir and reflux reaction; wherein, the mass ratio of graphene and hexamethylenetetramine is 4:1, the temperature of stirring and reflux reaction is 120°C, and the time is After 1 h, the second dispersion liquid was prepared.

[0069] Centrifuge the above-mentioned second dispersion, wherein the centrifugation speed...

Embodiment 3

[0079] 1. Preparation of graphene dispersion

[0080] Put non-oxidized graphene (the number of layers is 1-9 layers, and the average particle size is less than or equal to 2 μm) in deionized water, and then add sodium dodecyl sulfate for ultrasonic dispersion, wherein: the mixture of graphene and sodium dodecyl sulfate The mass ratio is 10:1; ultrasonic dispersion is carried out twice, the frequency of the first ultrasonic dispersion is 80kHZ, and the dispersion time is 1h. The frequency of the secondary ultrasonic dispersion is 40kHZ, and the dispersion time is 3h to obtain the first dispersion liquid.

[0081] Add hexamethylenetetramine to the above-mentioned first dispersion liquid, stir and reflux reaction; wherein, the mass ratio of graphene and hexamethylenetetramine is 8:1, the temperature of stirring and reflux reaction is 80°C, and the time is 3h, the second dispersion liquid was prepared.

[0082] Centrifuge the above-mentioned second dispersion liquid, wherein the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry breaking strength | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com