Fast bonding process of silica gel and PET

A kind of silica gel, fast technology, applied in the field of rapid bonding process of silica gel and PET, can solve the problems of long time, silica gel can not be bonded, loss of flexibility of silica gel and PET, etc., to improve production efficiency, solve the problem of glue opening, improve inertia The effect of the factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

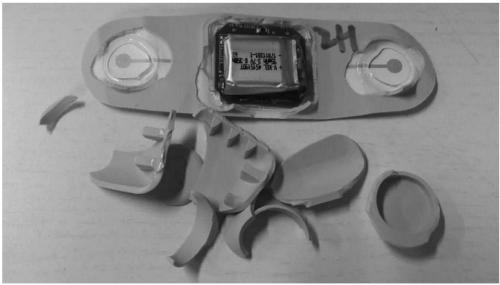

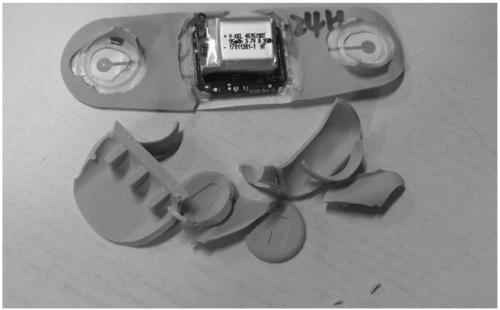

Image

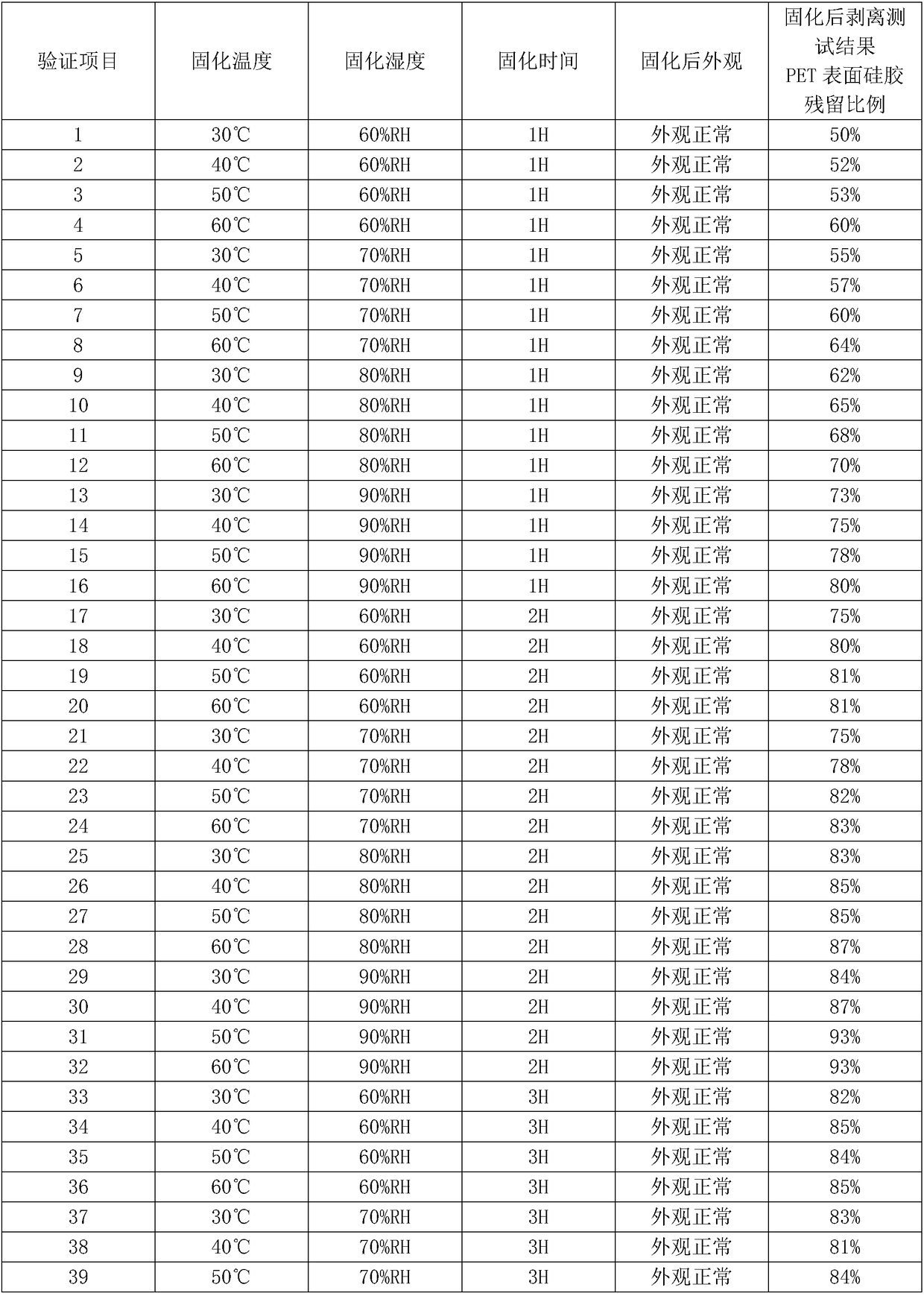

Examples

Embodiment 1

[0058] A rapid bonding process of silicone and PET, including:

[0059] Silica gel preparation steps: provide a silica gel, and after the bonding surface of the silica gel is subjected to ultrasonic cleaning steps, laser treatment steps and plasma treatment steps in sequence, pretreated silica gel is obtained; the specific treatment process of the ultrasonic cleaning step is as follows: the silica gel is cleaned by an ultrasonic cleaner. The bonding surface is cleaned, and then the liquid on the surface of the silica gel is dried; the ultrasonic cleaning time is 10 minutes, and the cleaning temperature is 30°C; the specific process of the laser treatment step is as follows: laser treatment is performed on the bonding surface of the silica gel by a laser machine; The treatment time is 2min, and the treatment power is 45%×1000W. The specific treatment process of the plasma treatment step is as follows: the bonding surface of the silica gel is subjected to plasma treatment by a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com