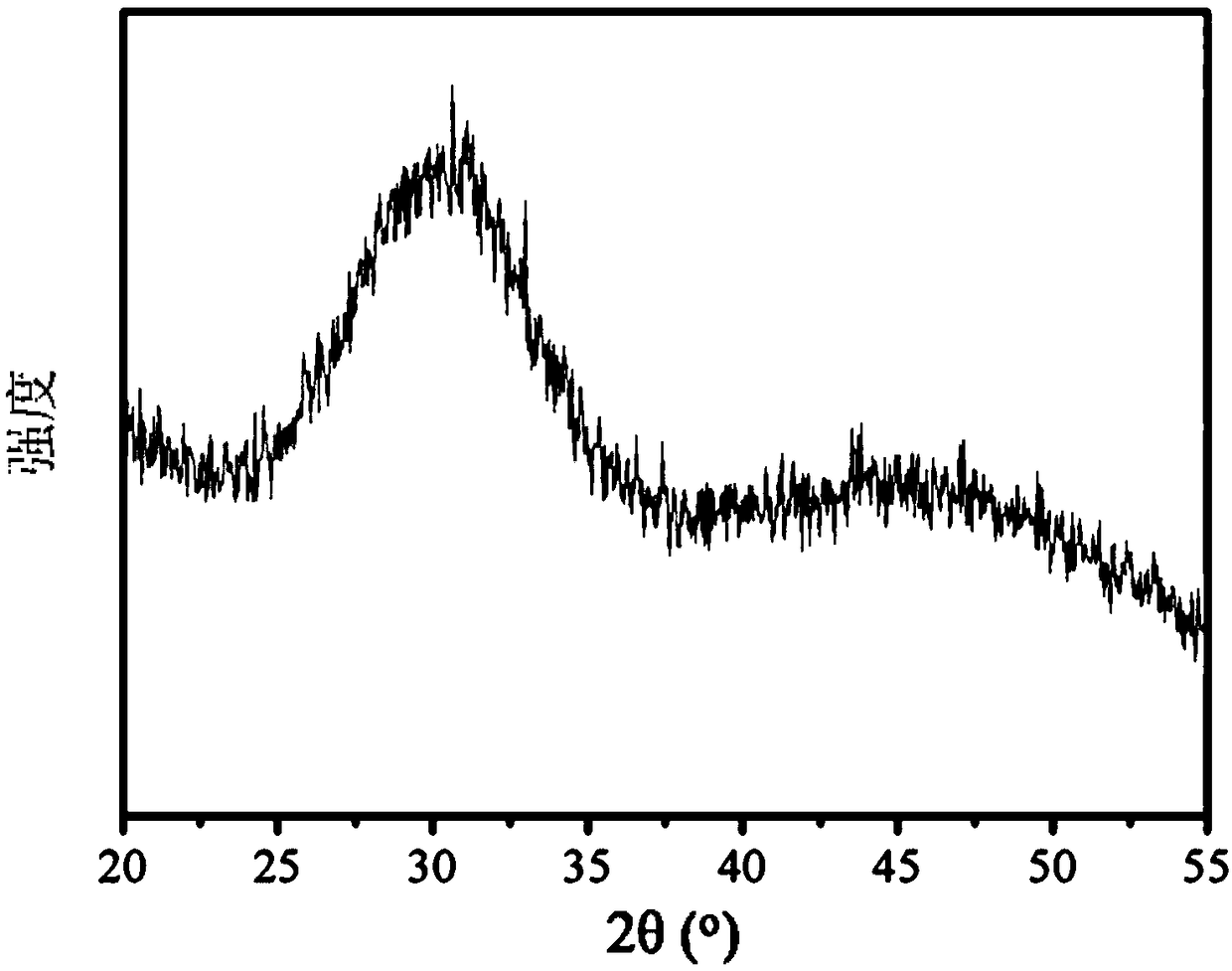

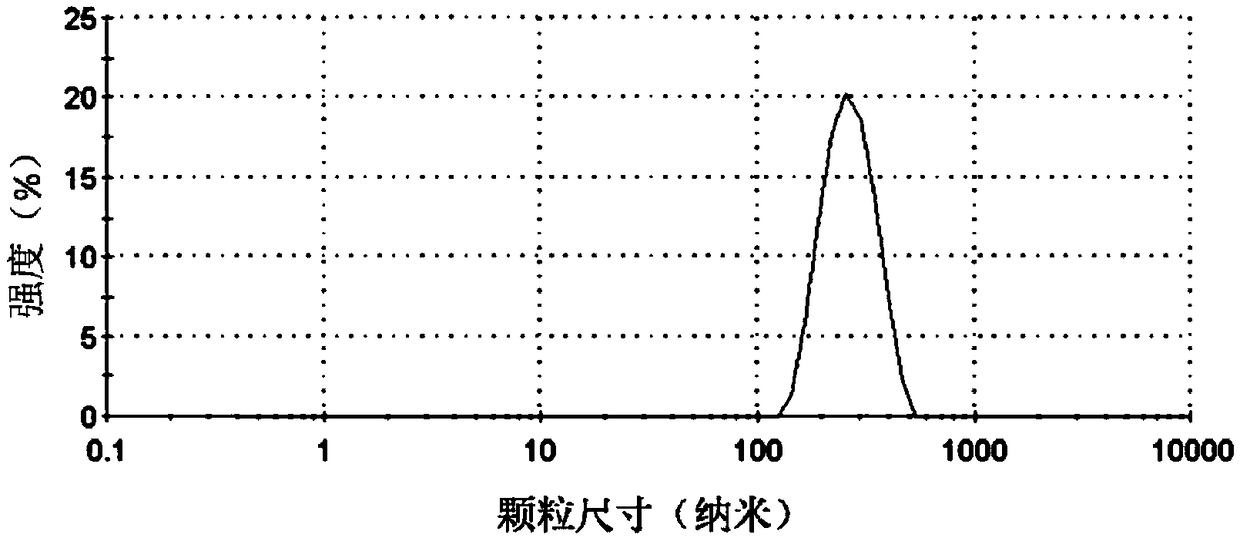

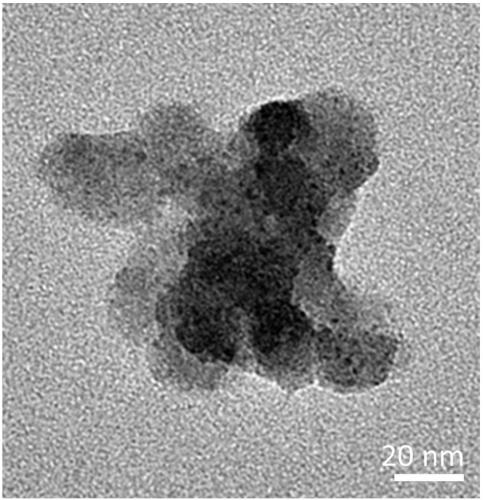

Amorphous calcium phosphate-polyacrylic acid hybridized nano material and preparation method and application thereof

A nanomaterial, crystalline calcium phosphate technology, applied in the field of biomedical materials, can solve the problems of non-degradable and poor biocompatibility, and achieve the effects of improving stability, enhancing development, and degrading quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Solution preparation: weigh 240mg of Ca(NO 3 ) 2 4H 2 O and 36mg of Mg(NO 3 ) 2 ·6H 2 O was dissolved in 50 mL of deionized water, and stirred evenly to obtain a mixed solution A. Weigh 110mg of (NH 4 ) 2 HPO 4 and 40 mg of PAA were dissolved in 200 mL of deionized water, stirred evenly to obtain a mixed solution B, and ammonia water was added drop by drop to adjust the pH to 9.5.

[0040] Wet chemical precipitation: Add the mixed solution A prepared in the previous step into the mixed solution B dropwise at a rate of 1 mL / min. Stir magnetically at 500 rpm for 1 hour.

[0041] Cleaning: after the reaction, centrifuge at 4000rpm. After centrifugation, remove the supernatant, collect the precipitate, add 50 mL of deionized water, and ultrasonically disperse to obtain a dispersion.

[0042] Dialysis: Inject the dispersion into a 8000-14000Da dialysis membrane, perform dialysis for 24 hours, and change the water every 6 hours. The goal is to remove unwrapped pol...

Embodiment 2

[0046] Solution preparation: Weigh 267mg Ca(NO 3 ) 2 4H 2 O was dissolved in 50 mL of deionized water, and stirred evenly to obtain a mixed solution A. Weigh 110mg (NH 4 ) 2 HPO 4 and 40 mg of PAA were dissolved in 200 mL of deionized water, stirred evenly to obtain a mixed solution B, and ammonia water was added drop by drop to adjust the pH to 9.5.

[0047] Wet chemical precipitation: Add the mixed solution A prepared in the previous step to the mixed solution B dropwise at a rate of 1 mL / min. Stir magnetically at 500 rpm for 1 hour.

[0048] Cleaning: after the reaction, centrifuge at 4000rpm. After centrifugation, remove the supernatant, collect the precipitate, add 50 mL of deionized water, and ultrasonically disperse to obtain a dispersion.

[0049] Dialysis: Inject the dispersion into a 8000-14000Da dialysis membrane, perform dialysis for 24 hours, and change the water every 6 hours. The goal is to remove unwrapped polyacrylic acid molecules.

[0050] Drying: ...

Embodiment 3

[0052] Solution preparation: Weigh 227mg Ca(NO 3 ) 2 4H 2 O and 54mg Mg(NO 3 ) 2 ·6H 2 O was dissolved in 50 mL of deionized water, and stirred evenly to obtain a mixed solution A. Weigh 110mg (NH 4 ) 2 HPO 4 and 40 mg of PAA were dissolved in 200 mL of deionized water, stirred evenly to obtain a mixed solution B, and ammonia water was added drop by drop to adjust the pH to 9.5.

[0053] Wet chemical precipitation: Add the mixed solution A prepared in the previous step to the mixed solution B dropwise at a rate of 1 mL / min. Stir magnetically at 500 rpm for 1 hour.

[0054] Cleaning: after the reaction, centrifuge at 4000rpm. After centrifugation, remove the supernatant, collect the precipitate, add 50 mL of deionized water, and ultrasonically disperse to obtain a dispersion.

[0055] Dialysis: Inject the dispersion into a 8000-14000Da dialysis membrane, perform dialysis for 24 hours, and change the water every 6 hours. The goal is to remove unwrapped polyacrylic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com