A delayed coking process for preparing coal-based needle coke

A delayed coking and needle coke technology, which is applied in the multi-tower delayed coking process field, can solve the problems of solvent coking, difficult long-term stable operation of the process flow, and small proportion of petroleum-based raw materials, and achieves the effect of avoiding coking and clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

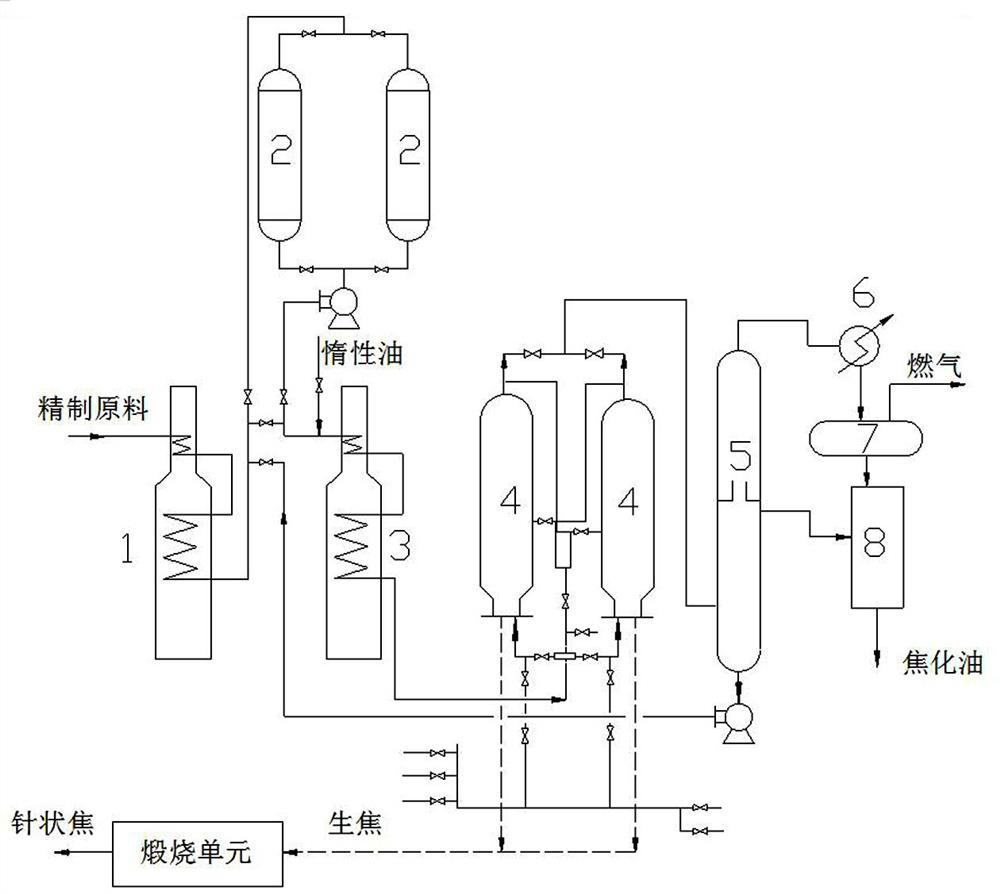

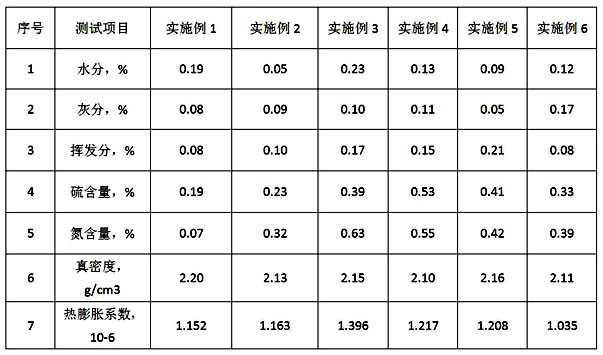

[0025] like Figure 1-2 As shown, a delayed coking process for preparing coal-based needle coke, the specific steps are as follows:

[0026] 1. The medium-temperature coal tar pitch is the refined raw material after solvent pretreatment. The content of quinoline insolubles in the refined raw material is 0.08%. The refined raw material is heated to 395°C by the low-temperature heating furnace 1 and then sent to the thermal polymerization tower 2. In a nitrogen atmosphere, Under the conditions of reaction temperature 390°C and reaction pressure 0.1MPa, stir for 3h;

[0027] 2. When the mesophase content of the material reaches 35%, the material containing the mesophase obtained in the thermal polymerization kettle and diesel oil are sent into the high-temperature heating furnace 3 together;

[0028] 3. Raise the temperature of the mixed material in the high-temperature heating furnace 3 to 486°C, and send the mixed material into the coke tower;

[0029] 4. Control the temperat...

Embodiment 2

[0033] A delayed coking process for preparing coal-based needle coke, the specific steps are as follows:

[0034] 1. The refined raw material of high-temperature coal tar after solvent pretreatment, the content of quinoline insolubles in the refined raw material is 0.03%, and the refined raw material is heated to 386 °C by the low-temperature heating furnace 1 and then sent to the thermal polymerization tower 2, in a nitrogen atmosphere, Under the conditions of reaction temperature 380°C and reaction pressure 0.2MPa, stir for 1.5h;

[0035] Two, when the mesophase content of the material reaches 32%, the mixture of the material containing the mesophase obtained in the thermal polymerization kettle and tetralin and diesel oil is jointly sent into the high-temperature heating furnace 3;

[0036] 3. Raise the temperature of the mixed material in the high-temperature heating furnace 3 to 486°C, and send the mixed material into the coke tower;

[0037] 4. Control the temperature i...

Embodiment 3

[0041] A delayed coking process for preparing coal-based needle coke, the specific steps are as follows:

[0042] 1. The medium-temperature coal tar pitch is a refined raw material after solvent pretreatment. The content of quinoline insolubles in the refined raw material is 0.05%. The refined raw material is heated to 430°C by a low-temperature heating furnace 1 and sent to a thermal polymerization tower 2. In a nitrogen atmosphere, Under the conditions of reaction temperature 425°C and reaction pressure 0.4MPa, stir for 2h;

[0043] 2. When the mesophase content of the material reaches 40%, the material containing the mesophase obtained in the thermal polymerization kettle and the diesel oil are jointly sent into the high-temperature heating furnace 3;

[0044] 3. Raise the temperature of the mixed material in the high-temperature heating furnace 3 to 505°C, and send the mixed material into the coke tower;

[0045]4. Control the temperature in the coke tower to 470°C, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com