Winnowing impurity removal and incineration disposal device for industrial solid waste

A technology of winnowing and removing impurities and industrial solid waste, which is applied in the direction of incinerator, combustion type, solid separation, etc. It can solve problems such as blockage, uneven fluidization of air distribution, and influence on normal operation of boilers, so as to avoid fluidization dead zone Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

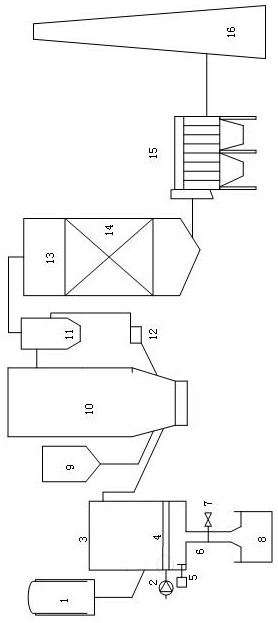

[0030] An industrial solid waste wind separation impurity removal and incineration disposal device, which consists of: solid waste bin 1, air separation device 3, coal hopper 9, fluidized bed incinerator 10, cyclone separator 11, and feeder 12 , flue shaft 13, dust collector 15 and chimney 16;

[0031] The solid waste bin is connected to the solid waste inlet at the lower part of the wind separator;

[0032] The gas-solid outlet of the air separator is connected to the solid waste inlet of the lower conical section of the fluidized bed incinerator;

[0033] The flue gas outlet on the upper part of the fluidized bed incinerator is connected to the flue gas inlet of the cyclone separator, and the coarse ash outlet at the bottom of the cyclone separator is connected to the inlet of the feeder. The outlet of the feeder is connected with the material return port arranged in the lower cone section of the fluidized bed incinerator.

Embodiment 2

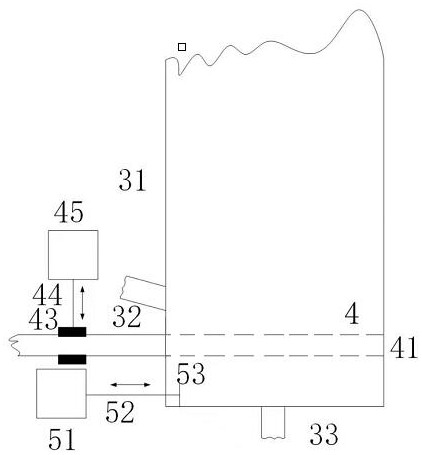

[0035] According to the wind separation impurity removal and incineration disposal device for industrial solid waste described in Embodiment 1, the air separation device includes a furnace wall 31, a feed pipe 32 and a miscellaneous discharge pipe 33, and the lower part of the air separation device is arranged to Wind device, the lower part of the air outlet device is fixed with a scraper cleaner 5, which is used to push the miscellaneous materials in the lower part of the air outlet pipe to the miscellaneous pipe, and the described miscellaneous pipe is connected with the miscellaneous pipe 6, and then It is connected to the miscellaneous material bin 8 through the electromagnetic gate valve 7 .

Embodiment 3

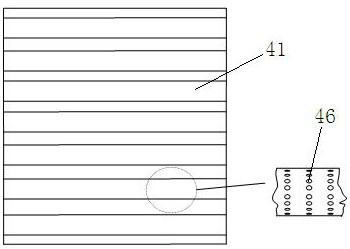

[0037] According to the wind separation, impurity removal and incineration disposal device for industrial solid waste described in Embodiment 1 or 2, the air outlet device includes a blower 2, a plurality of air outlet pipes 4, a pipe rail 42, a surrounding support 43, a connecting rod 44 and pusher 45;

[0038] A plurality of said air outlet pipes are arranged in parallel and juxtaposed, fixed by said peripheral support and said pipe rail, and the end of said pipe rail is inserted into the groove of said furnace wall;

[0039] The outlet duct of the blower has a thick pipe wall, and the inlets at both ends of each of the outlet ducts are inserted into the grooves of the outlet duct of the blower;

[0040] The surrounding support is fixed to the connecting rod, and the connecting rod is fixed through the push-out end of the pushing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com