Super-strong-adsorptivity concrete rheological agent and preparation method thereof

A technology of rheological agent and concrete, which is applied in the field of water reducing agent for cement concrete, can solve the problems of complex preparation engineering process, difficult industrial production, harsh reaction conditions, etc., achieve good controllability, reduce production volume, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

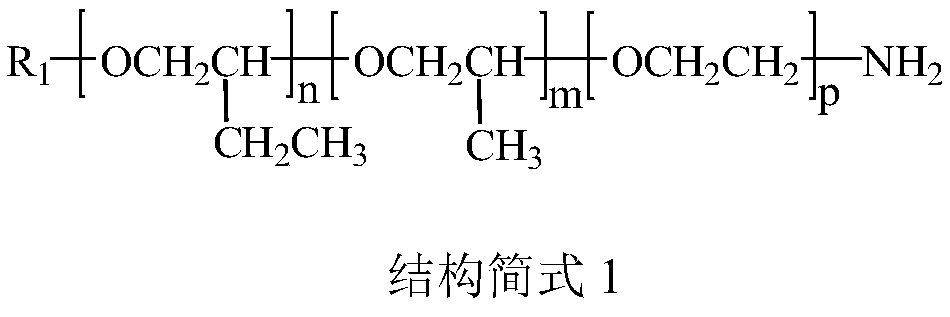

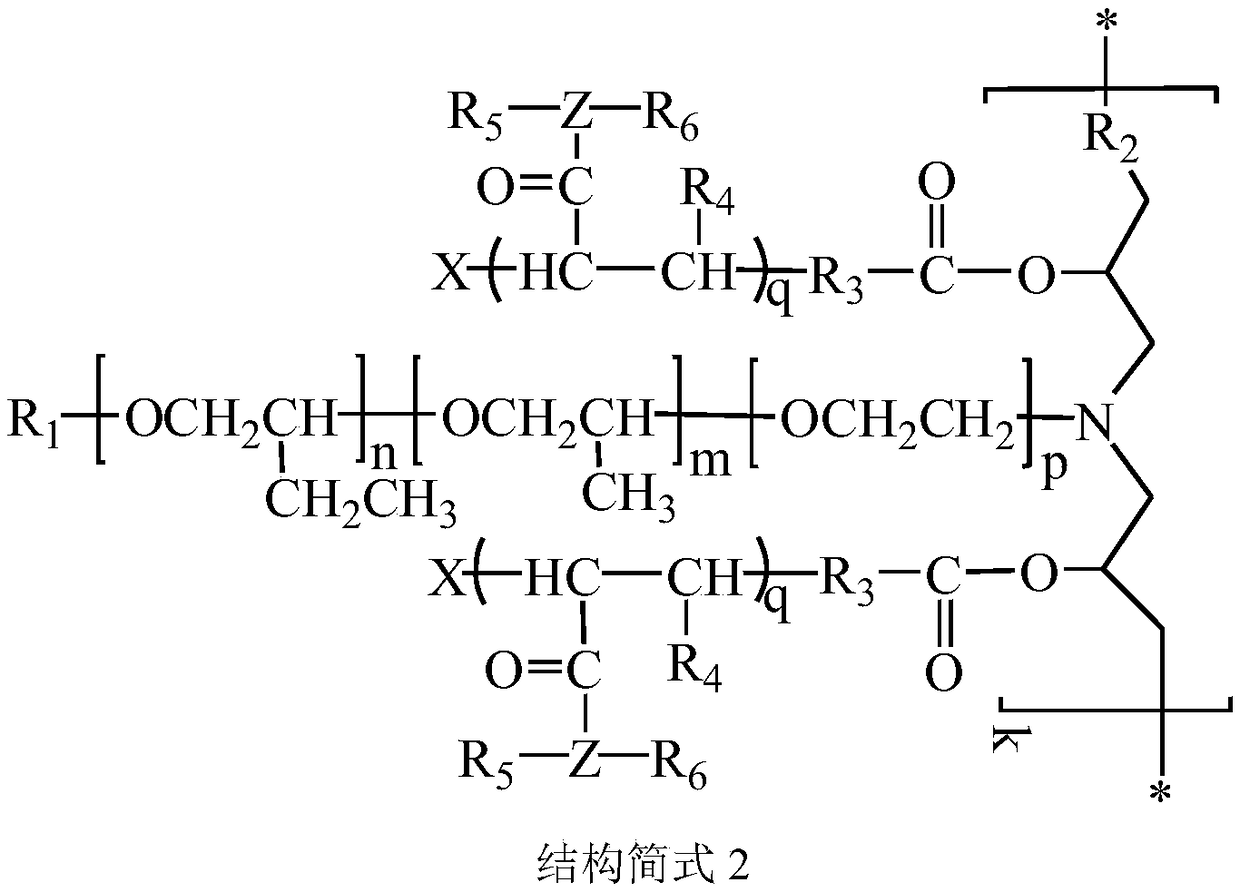

Method used

Image

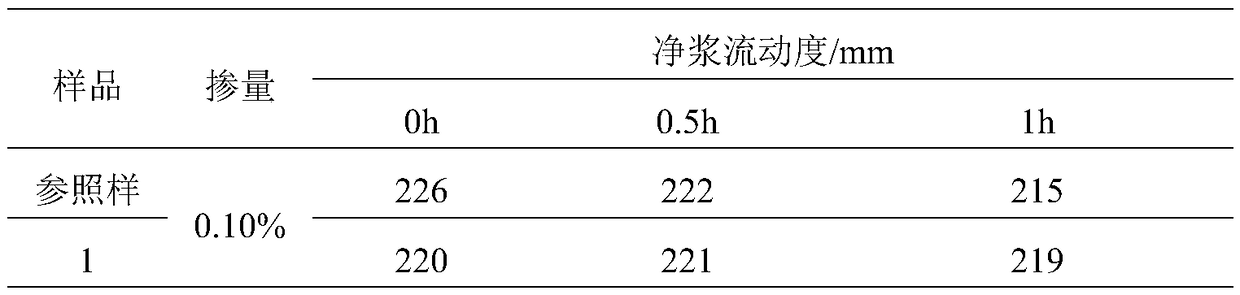

Examples

Embodiment 1

[0032] 1) Preparation of halogen-terminated polyether (ATRP initiator):

[0033] 10mol amino-terminated polyether (its R 1is methyl, m and n are both zero, p=10, and the weight average molecular weight is 500), 11mol1,3-butadiene diepoxide is stirred at normal temperature and pressure for 5h to carry out amino-epoxy ring-opening polymerization reaction , to realize the grafting of amino-terminated polyether on the main chain into a side chain polymer. After the reaction is completed, after dehydration and drying, 22mol 2-bromoisobutyryl chloride is added for esterification reaction for 0.5h to obtain bromo-terminated polyether (ATRP initiator).

[0034] 2) Preparation of super-absorbent concrete rheological agent:

[0035] React 10mol bromo-terminated polyether (ATRP initiator), 20mol acrylic acid and 0.1mol CuBr / pentamethyldiethylenetriamine (PMDETA) at 50°C for 120min, add sodium hydroxide to adjust the pH value to 6 to obtain a super strong Adsorption concrete rheologica...

Embodiment 2

[0037] 1) Preparation of halogen-terminated polyether (ATRP initiator):

[0038] 10mol amino-terminated polyether (its R 1 is methyl, m and n are both zero, p=17, and the weight average molecular weight is 800), 10.1mol1,5-hexadiene diepoxide is stirred at normal temperature and pressure for 1h to carry out amino-epoxy ring-opening polymerization The reaction is to realize the grafting of amino-terminated polyether on the main chain to form a polymer with side chains. After the reaction is completed, after dehydration and drying, 20.1mol 2-bromoisobutyryl bromide is added for esterification reaction for 0.1h to obtain terminal bromine based polyether (ATRP initiator).

[0039] 2) Preparation of super-absorbent concrete rheological agent:

[0040] React 10mol of bromo-terminated polyether (ATRP initiator), 26mol of methacrylic acid and 0.2mol of CuCl / HMTETA at 55°C for 240min, add sodium methoxide to adjust the pH value to 7, and obtain a superabsorbent concrete rheological a...

Embodiment 3

[0042] 1) Preparation of halogen-terminated polyether (ATRP initiator):

[0043] 10mol amino-terminated polyether (its R 1 is methyl, m=0, n=7, p=10, weight average molecular weight is 1000), 10.2mol bis(2,3-epoxycyclopentyl)ether was stirred at normal temperature and pressure for 5h for amino- Epoxy ring-opening polymerization reaction to realize the grafting of amino-terminated polyether on the main chain to form a side chain polymer. After the reaction is completed, after dehydration and drying, 21.1mol 2-bromoisobutyryl chloride is added for esterification reaction for 0.9h This results in a bromo-terminated polyether (ATRP initiator).

[0044] 2) Preparation of super-absorbent concrete rheological agent:

[0045] React 10mol of bromo-terminated polyether (ATRP initiator), 30mol of hydroxymethyl acrylate and 0.3mol of CuBr / tetrakis[(2-pyridyl)methyl]ethylenediamine (TPEN) at 60°C for 90min, add sodium ethoxide to adjust the pH A value of 7 means that a superabsorbent co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com