Soil crushing device

A crushing and soil technology, applied in grain processing, etc., can solve the problems of dusty, environmental pollution, etc., and achieve the effects of improving environmental protection, reducing dust particles, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

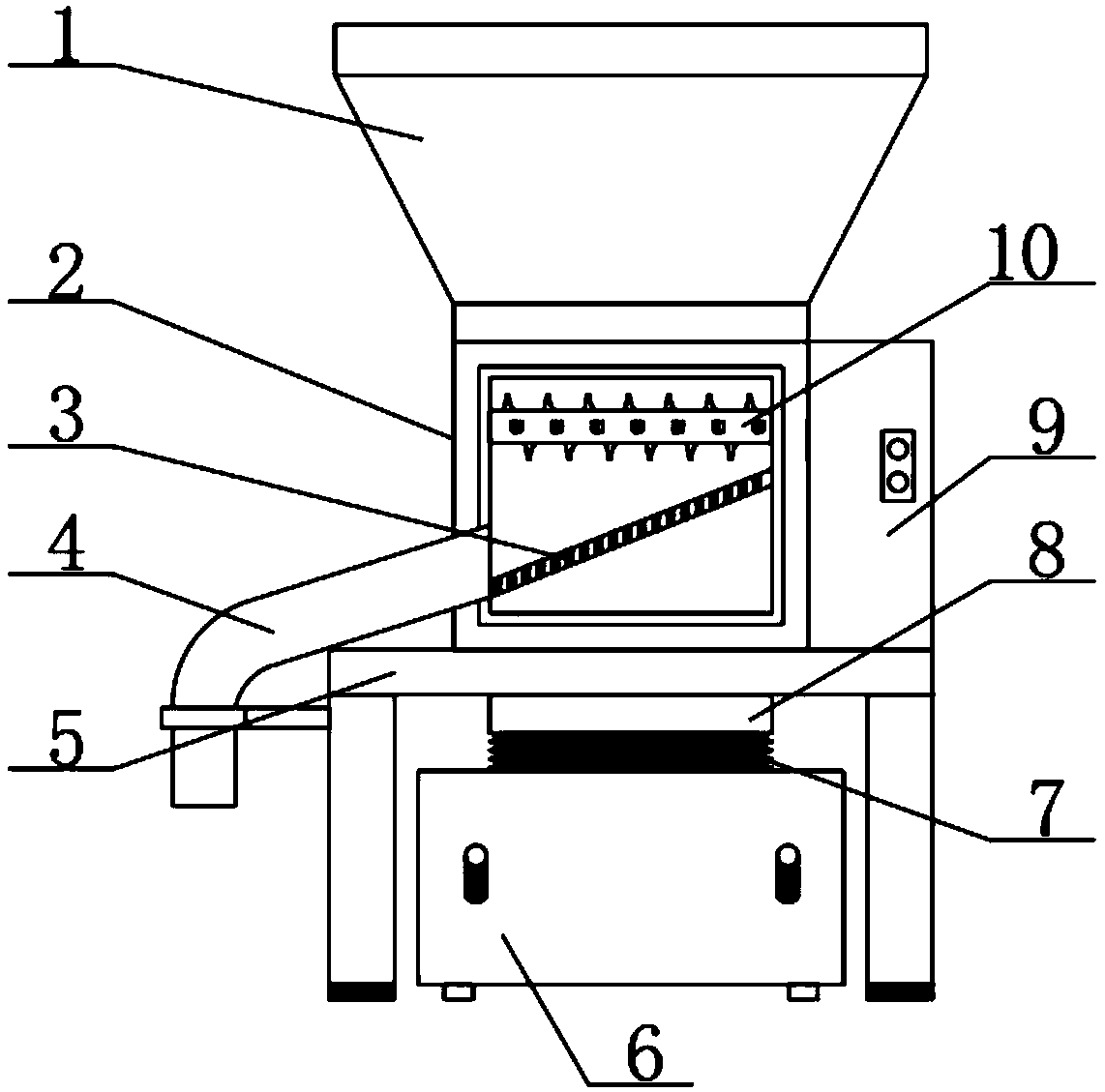

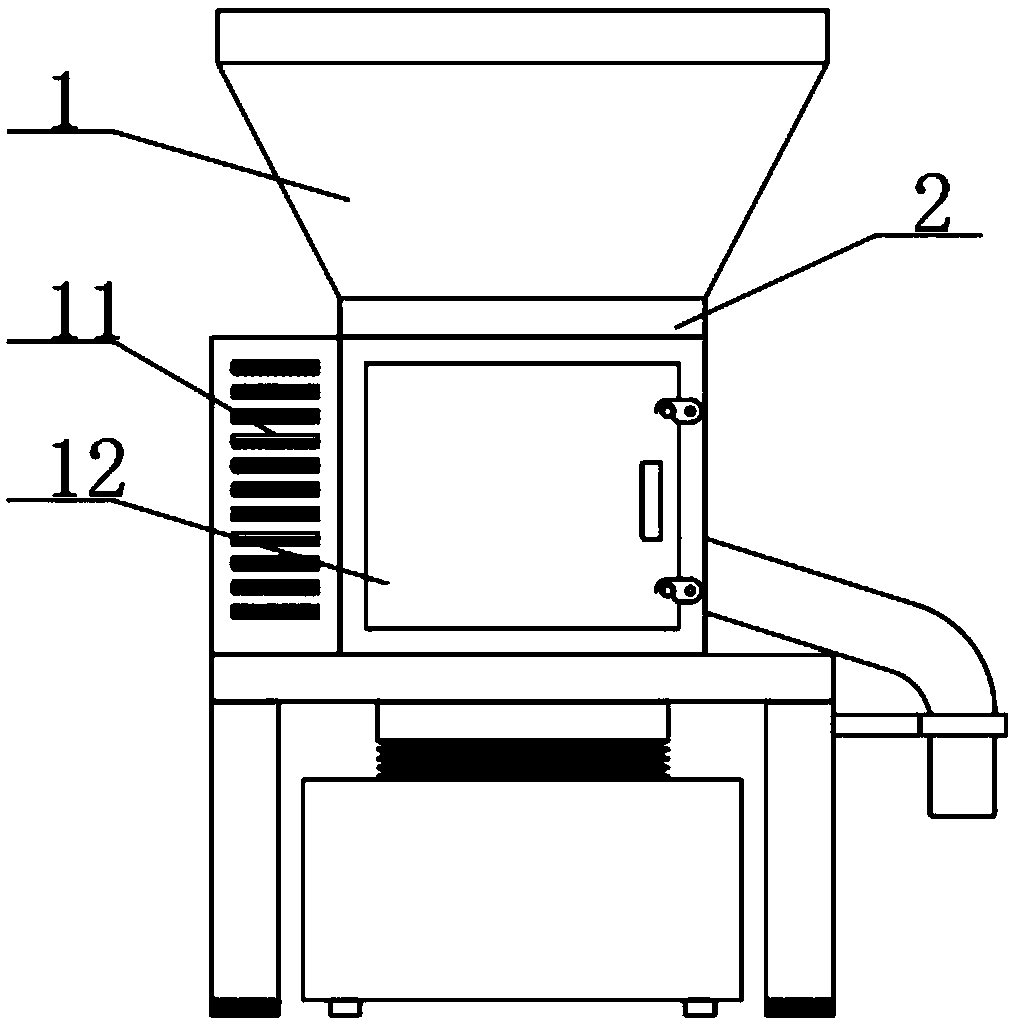

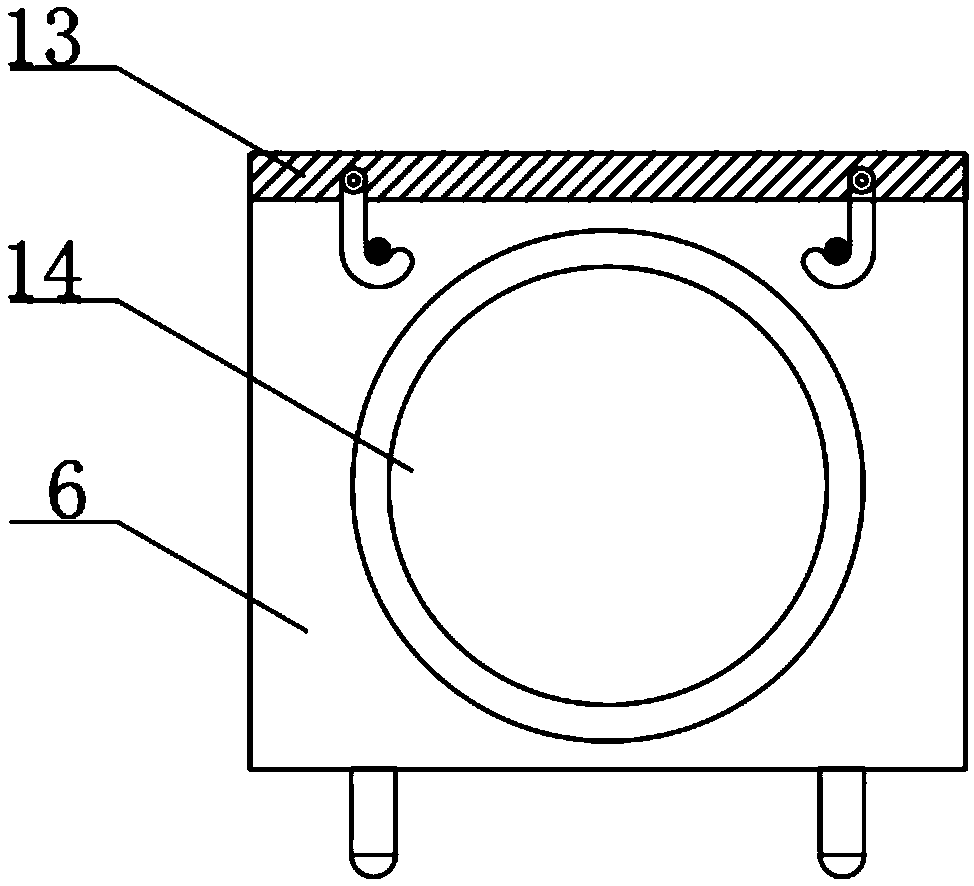

[0022] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a technical solution: a soil crushing device, including a device main body 2, a feeding hopper 1 is provided on the upper end of the device main body 2, a bracket 5 is provided on the lower end, and a first discharge port 4 and a first outlet 4 are respectively provided on both sides. Motor box 9, a servo motor 19 is arranged inside the motor box 9, a running water pipe 15 is arranged around the upper end surface of the hopper 1, and an atomizing nozzle 16 is symmetrically arranged on the inner surface of the hopper 1, and the tap water is sprayed in the form of water mist On the upper end surface of the hopper 1, to prevent dust from raising and causing pollution, the upper end of the main body 2 of the device is provided with intermeshing soil-crushing knives 10, the soil clods are squeezed and broken by the soil-crushing knives 10, and the lower end of the soil-crushing knives 10 is ...

Embodiment 2

[0027] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the present invention provides a technical solution: a soil crushing device, including a device main body 2, a feeding hopper 1 is provided on the upper end of the device main body 2, a bracket 5 is provided on the lower end, and a first discharge port 4 and a first outlet 4 are respectively provided on both sides. Motor box 9, a servo motor 19 is arranged inside the motor box 9, a running water pipe 15 is arranged around the upper end surface of the hopper 1, and an atomizing nozzle 16 is symmetrically arranged on the inner surface of the hopper 1, and the tap water is sprayed in the form of water mist On the upper end surface of the hopper 1, to prevent dust from raising and causing pollution, the upper end of the main body 2 of the device is provided with intermeshing soil-crushing knives 10, the soil clods are squeezed and broken by the soil-crushing knives 10, and the lower end of the soil-crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com