Polyionic liquid catalyst for catalytic conversion of CO2 at normal pressure and preparation method of polyionic liquid catalyst

A technology of polyionic liquid and ionic liquid, applied in the field of catalysts for CO2 catalytic conversion, can solve the problems of inconvenient recycling, high viscosity and high cost, and achieve the effects of less dosage, lower dosage and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

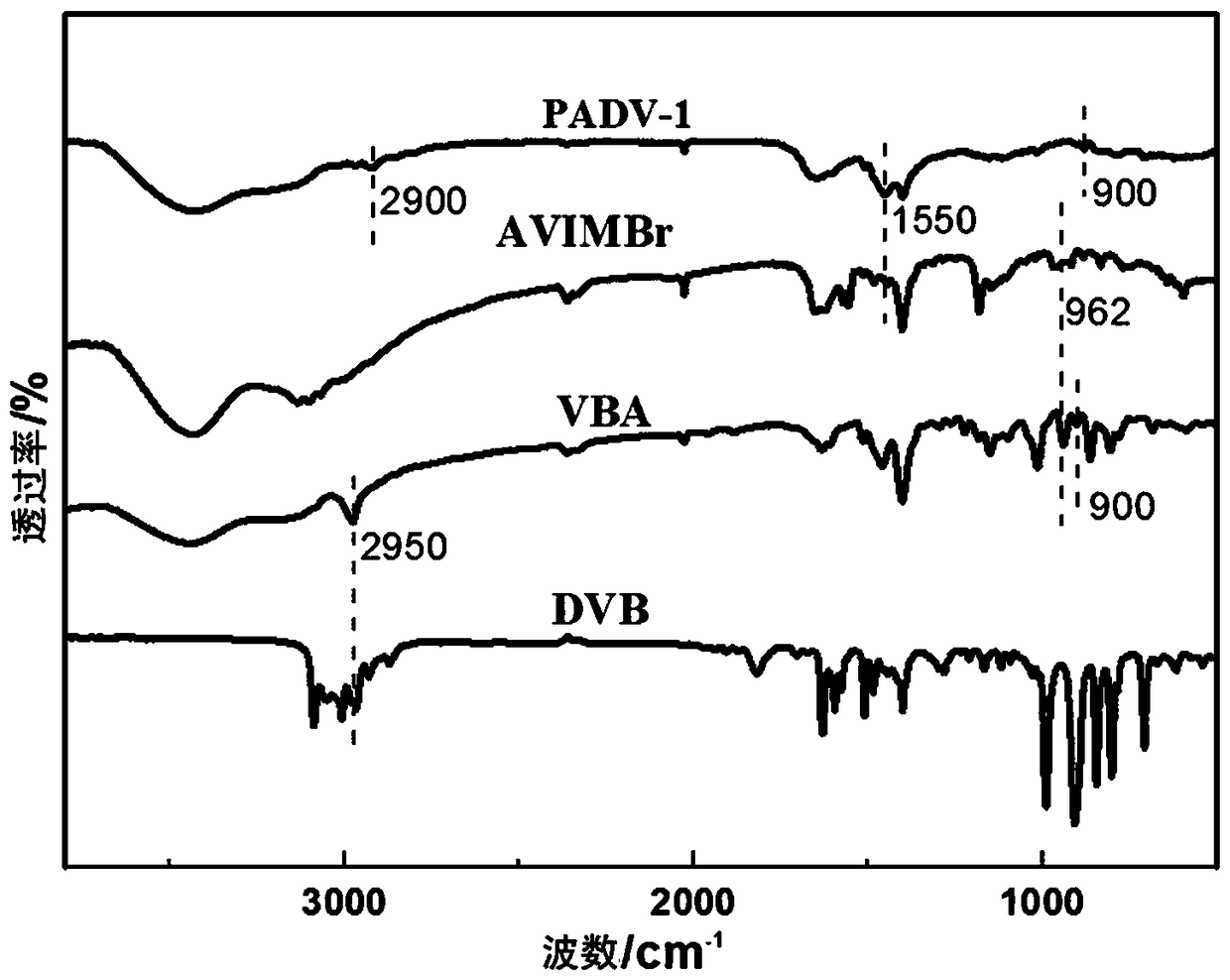

[0027] Weigh 11.29g (100mmol) of 1-vinylimidazole and 20.4g (100mmol) of 2-bromoethylamine hydrobromide, add 50ml of anhydrous acetonitrile, heat and stir at 75°C for 24h at reflux under nitrogen protection. After the reaction, the solid product was filtered out, washed with absolute ethanol, and dried under vacuum at room temperature for 12 hours to obtain 1-vinyl-3-ethylaminoimidazolium bromide·hydrobromic acid ([AVIM]Br·HBr). Dissolve [AVIM]Br HBr in a small amount of water, add equimolar NaOH to carry out neutralization reaction to remove hydrobromic acid, dry the product and remove water, dissolve it in a small amount of anhydrous methanol, and centrifugally filter to remove sodium bromide insoluble matter, 40 °C and vacuum-dried to prepare 14.2 g of amino ionic liquid 1-vinyl-3-ethylaminoimidazolium bromide ([AVIM]Br).

[0028] Weigh 2.29g (15mmol) of 4-chloromethylstyrene and 2.372g (23mmol) of triethylamine in 3ml of anhydrous methanol, under nitrogen protection, and h...

Embodiment 2

[0032] Weigh 1.09g (5mmol) of [AVIM]Br and dissolve it in 50ml of dimethyl sulfoxide, add 1.27g (5mmol) of VBA, 0.65g (5mmol) of DVB and 0.24g of AIBN, heat and stir at 70°C under the protection of nitrogen for reflux reaction 24h. Cool to room temperature after the reaction, add acetone to precipitate the product, centrifuge, and vacuum dry at 110° C. for 48 hours to prepare a polyionic liquid catalyst, labeled as PADV-2.

Embodiment 3

[0034] Weigh 0.436g (2mmol) of [AVIM]Br and dissolve it in 50ml of dimethyl sulfoxide, add 3.80g (15mmol) of VBA, 2.60g (20mmol) of DVB and 0.24g of AIBN, heat and stir at 70°C under the protection of nitrogen for reflux reaction 24h. Cool to room temperature after the reaction, add acetone to precipitate the product, centrifuge, and vacuum dry at 110° C. for 48 hours to prepare a polyionic liquid catalyst, labeled as PADV-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com