Polyamino acid based mussel bionic tissue adhesive and preparation method thereof

A polyamino acid and mussel-based technology, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as increasing patient pain, adverse reactions of tissues and organs, and immune system diseases, and achieve process parameters Ease of control, excellent biocompatibility, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

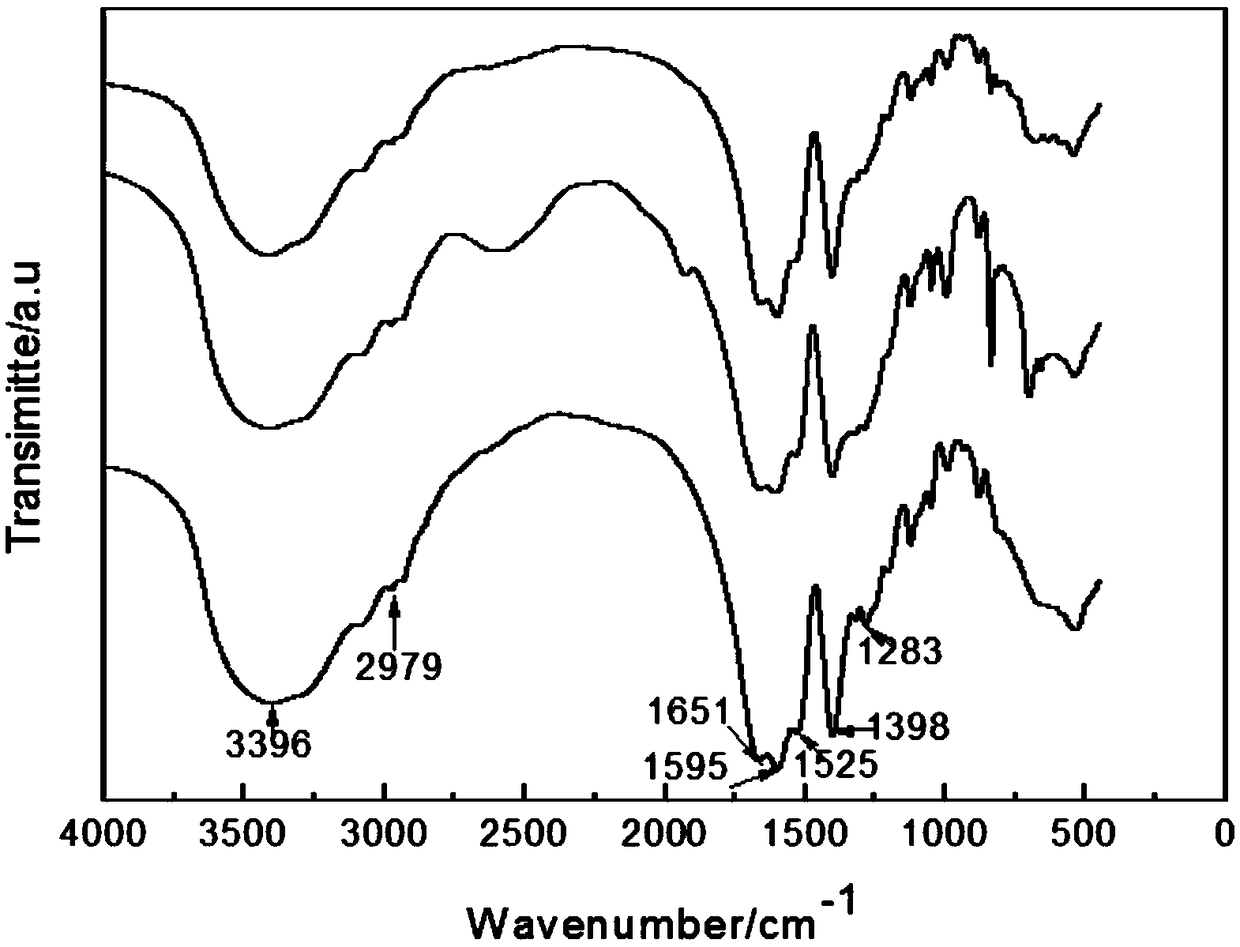

Method used

Image

Examples

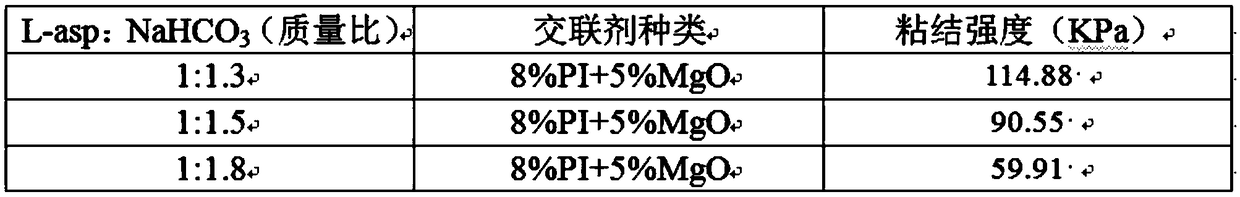

Embodiment 1

[0042] A. Weigh 10g of L-aspartic acid and 1g of 85% phosphoric acid according to the mass ratio of 10:1, pour them into a weighing bottle, add deionized water until the liquid surface completely covers the solid. Stir at 400r / min for 10 minutes. Then place it open, and heat at 200°C for 8 hours to undergo solid phase polymerization, and react to obtain a polysuccinimide prepolymer.

[0043] B. Dissolve the crude polysuccinimide above in an appropriate amount of N,N-dimethylformamide solution, and stir at 400 r / min for 2 hours while heating in a water bath at 40°C. Phosphoric acid and unreacted L-aspartic acid were removed by suction filtration. Add deionized water to precipitate, suction filter and wash with deionized water three times, and dry at 80°C to obtain a purified polysuccinimide prepolymer.

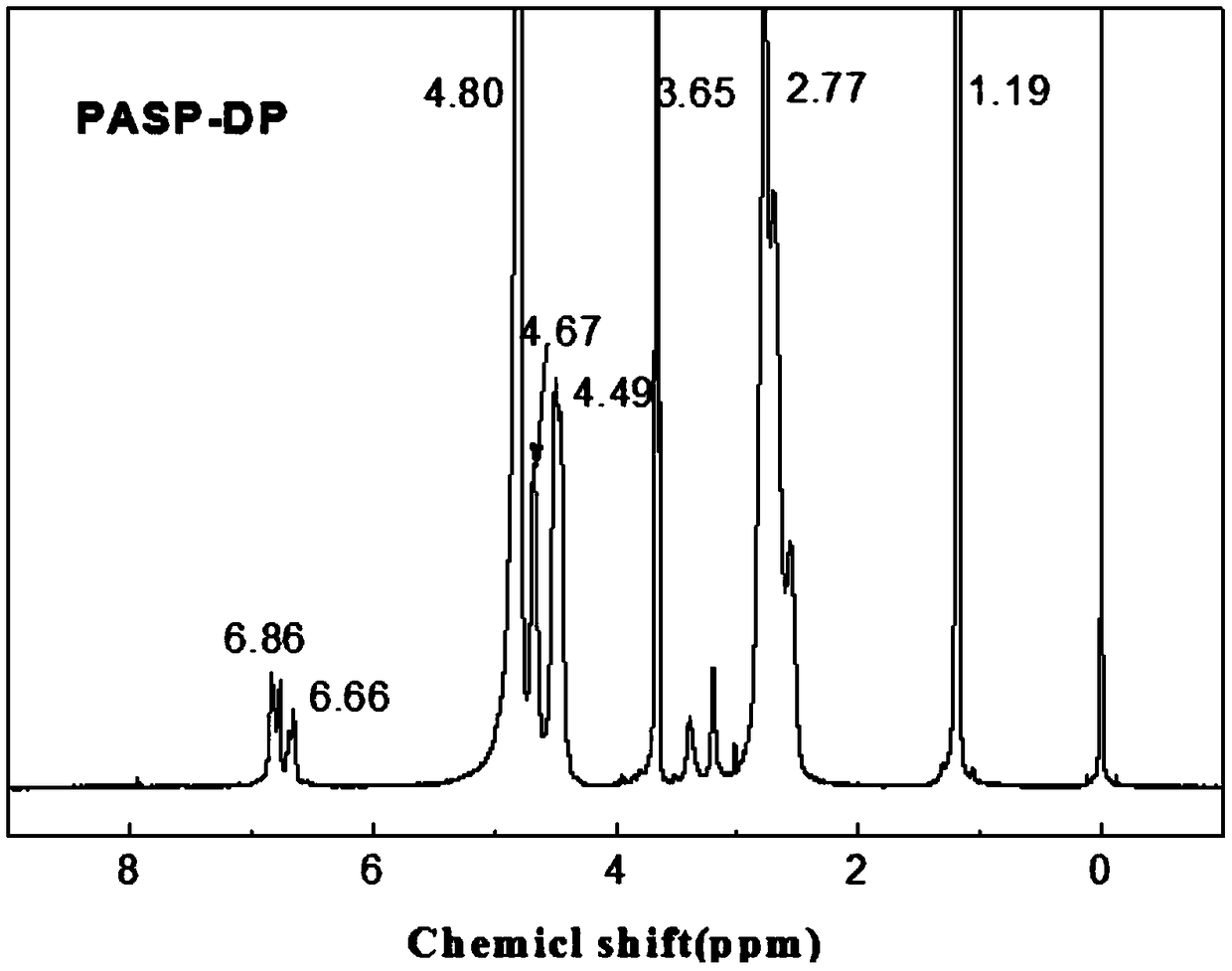

[0044] C. Weigh 5g (50mmol) polysuccinimide prepolymer, 9.5g (50mmol) dopamine hydrochloride, 6.5g (77mmol) sodium bicarbonate, dissolve in 100ml deionized water, react in a ...

Embodiment 2

[0047] A. Weigh 10g of L-aspartic acid and 1g of 85% phosphoric acid according to the mass ratio of 10:1, pour them into a weighing bottle, add deionized water until the liquid surface completely covers the solid. Stir at 400r / min for 10 minutes. Then it was left open and heated at 210°C for 10 hours to undergo solid phase polymerization. During this period, stir evenly after the deionized water is volatilized, and then crush the solid particles into powder and stir every hour. The reaction yields crude polysuccinimide.

[0048] B. Dissolve the crude polysuccinimide above in an appropriate amount of N,N-dimethylformamide solution, and stir at 400 r / min for 3 hours while heating in a water bath at 40°C. Phosphoric acid and unreacted L-aspartic acid were removed by suction filtration. Add deionized water to precipitate, suction filter and wash with deionized water three times, and dry at 80°C to obtain purified polysuccinimide.

[0049] C. Weigh 5g (50mmol) polysuccinimide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com