Bismuth ferrite based nano ceramic and preparation method

A technology of nano-ceramics and bismuth ferrite, which is applied in the field of preparation of non-polar non-metallic materials, can solve the problems of large leakage current, reduction of remanent polarization strength of bismuth ferrite ceramics, deterioration of ferroelectricity, etc., to reduce dielectric loss and leakage Current, improvement of ferromagnetism and ferroelectricity, effect of promoting orthorhombic phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

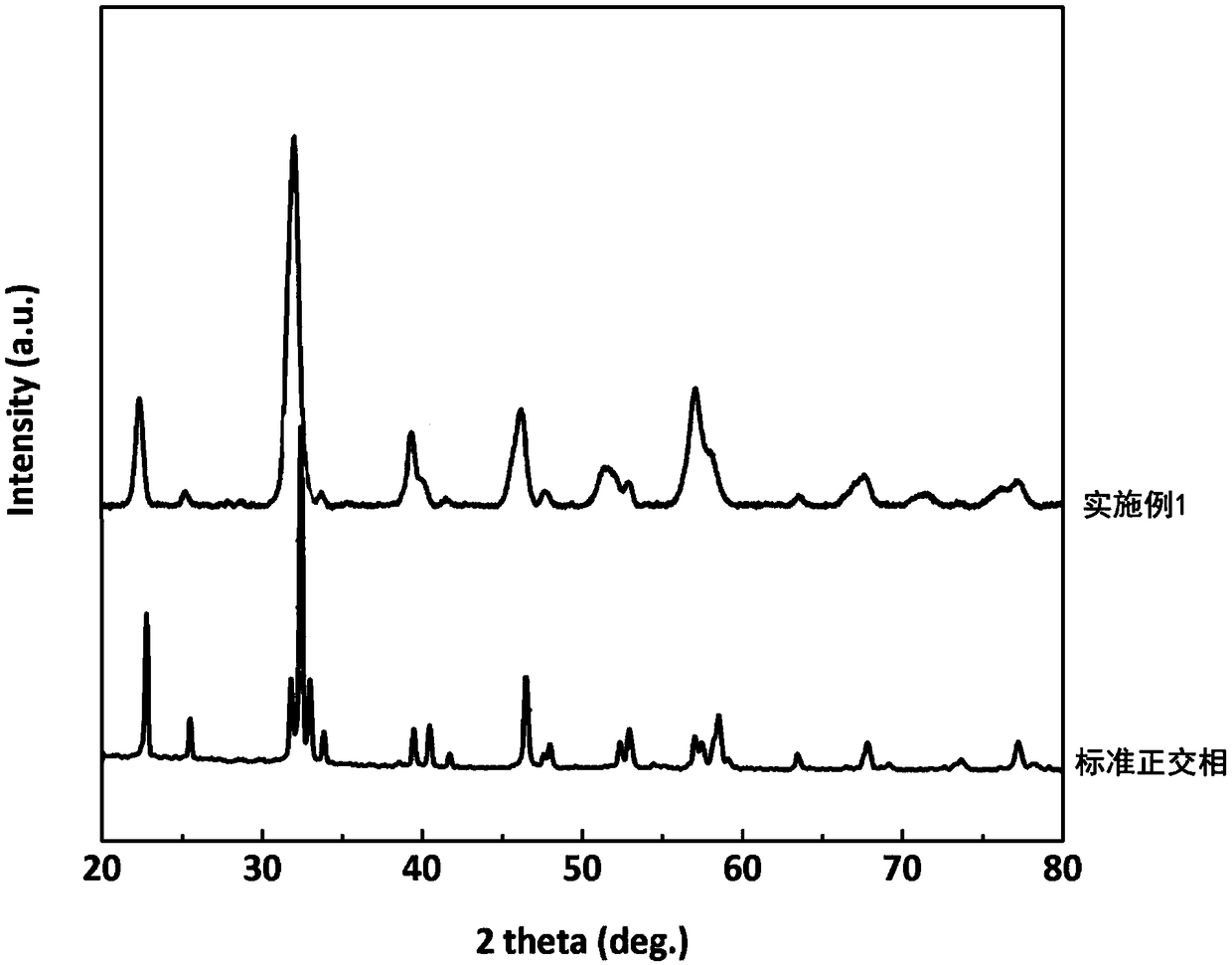

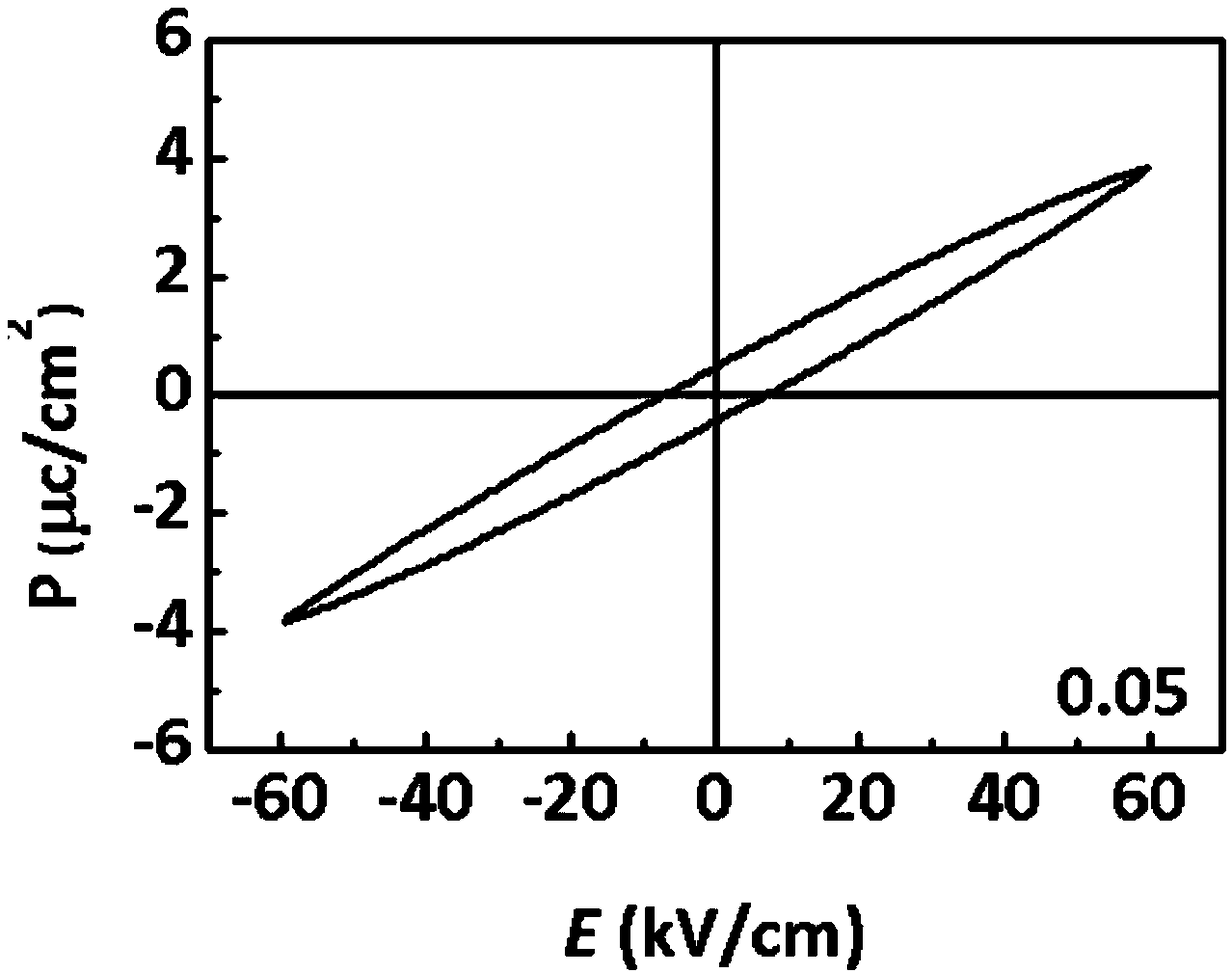

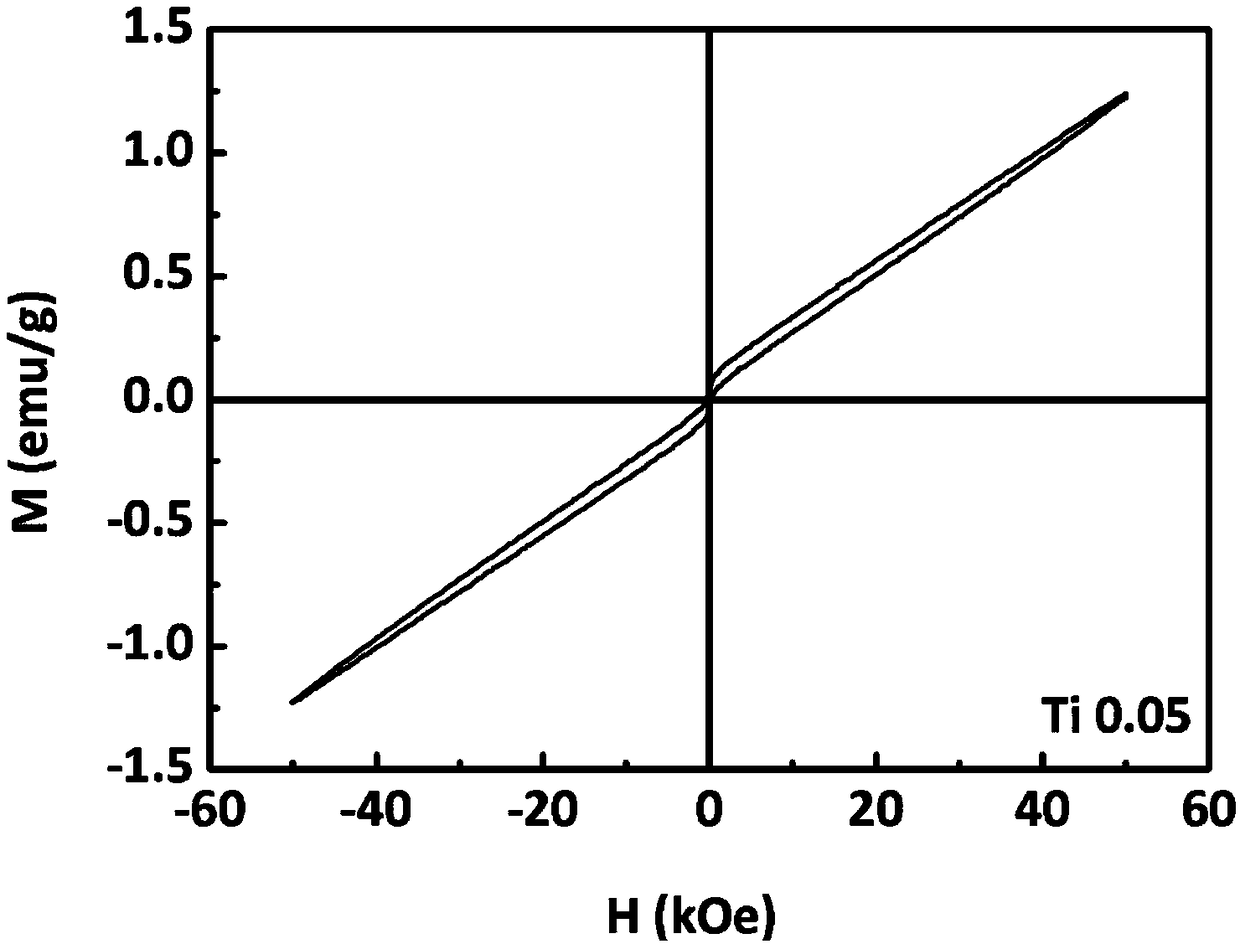

[0033] This embodiment proposes bismuth ferrite-based nano-ceramic, the chemical formula of its main component is Bi 0.8 Gd 0.2 Fe 1- x Ti x o 3 , where the value of x is Ti 4+ The doping ratio of x=0.05, Bi 0.8 Gd 0.2 Fe 1-x Ti x o 3 The phase of matter is orthorhombic.

[0034] The preparation method of the above-mentioned bismuth ferrite-based nano ceramics comprises the following steps:

[0035] (1) Weigh the bismuth source, iron source, gadolinium source and titanium source according to the molar ratio of the doping elements, mix and dissolve them in an organic solvent, and configure a mixed solution with a concentration of 0.1mol / L;

[0036] (2) Add additives to the mixed solution, the mol ratio of the additives to the mixed solution is 1:1, stir for 4 hours to obtain a sol;

[0037] (3) Drying the sol for 12 hours at a drying temperature of 120° C., finely grinding it to obtain a nanopowder;

[0038] (4) Filling the nano-powder into the graphite mold, perfo...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1, except that x=0.01, and the ratio of the orthorhombic phase generated by the lattice mutation is 67.9%.

Embodiment 3

[0055] This embodiment is basically the same as Embodiment 1, except that x=0.1, and the ratio of the orthorhombic phase generated by the lattice mutation is 76.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com