Method for disposing water containing massive algae on basis of calcium-peroxide-enhanced coagulation

A technology of calcium peroxide and high-algae water, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, flocculation/sedimentation water/sewage treatment, etc., and can solve the problem of chemical types, complex steps of chemical pretreatment process, and algae fragmentation and death , increase dissolved oxygen and other issues, to achieve the effect of improving coagulation effect, reducing dosage and promoting hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

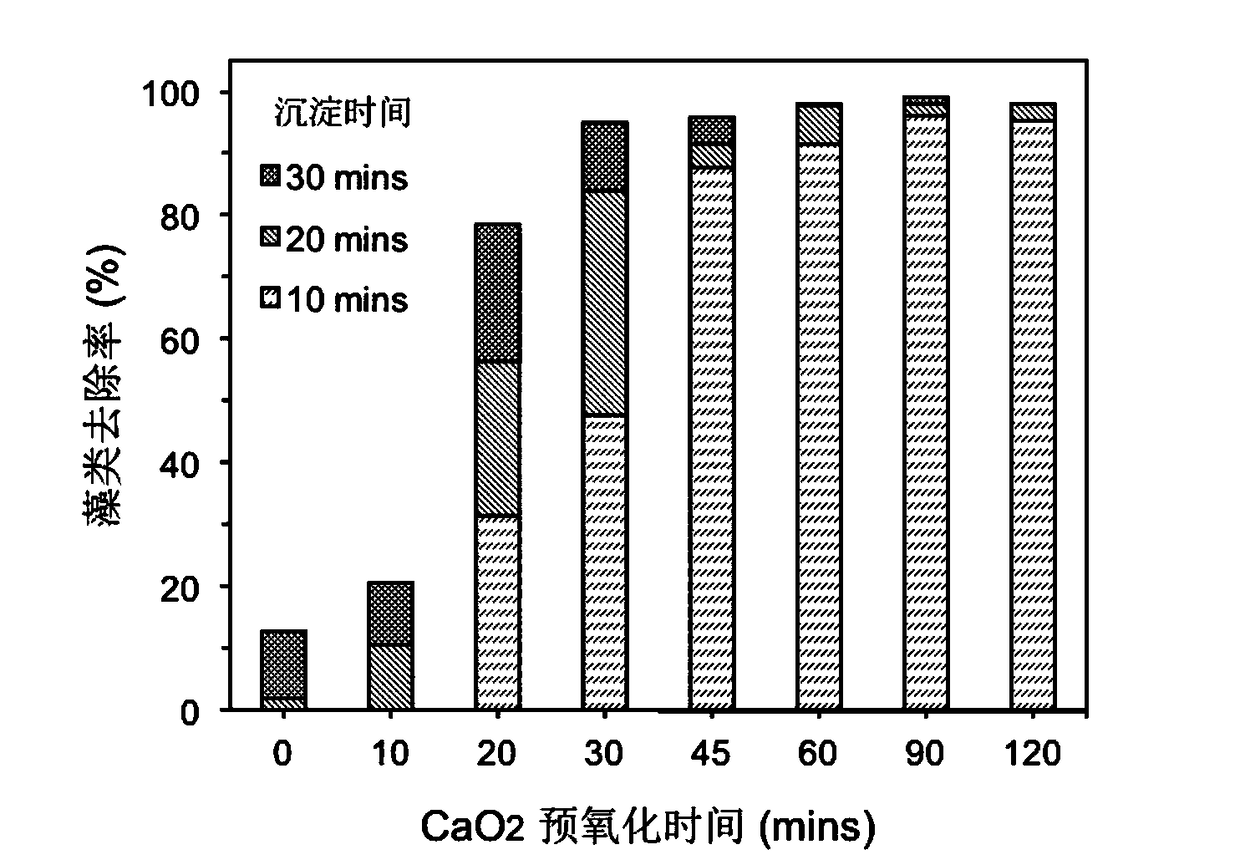

[0029] Comparison of the effects of different calcium peroxide preoxidation times on strengthening coagulation and sedimentation.

[0030] 1) Dilute Microcystis aeruginosa to about 2×10 with tap water 6 Algae / mL, respectively put into beakers to prepare for the experiment.

[0031] 2) The configured CaO 2 The solution is added to the algae water at a concentration of 0.5mmol / , fully stirred, and pre-oxidized for 0-120mins.

[0032] 3) Then add 0.1mmol / L ferrous sulfate coagulant (15.2mg / L FeSO 4 ) for coagulation, first rapid coagulation under the condition of 200r / min for 2mins, then coagulation under the condition of 50r / min for 15mins, and finally settling for 10, 20, 30mins, sampling and testing.

[0033] the result shows( figure 1 ), with CaO 2 The removal rate of algae gradually increased with the increase of preoxidation time. When the pre-oxidation time=30mins, the removal rate of algae measured after 30mins of coagulation and sedimentation can be as high as 94.9...

Embodiment 2

[0035] Comparison of the effects of different calcium peroxide oxidant dosing sequences on strengthening coagulation and sedimentation.

[0036] 1) Dilute Microcystis aeruginosa to about 2×10 with tap water 6 Algae / mL, respectively put into beakers to prepare for the experiment.

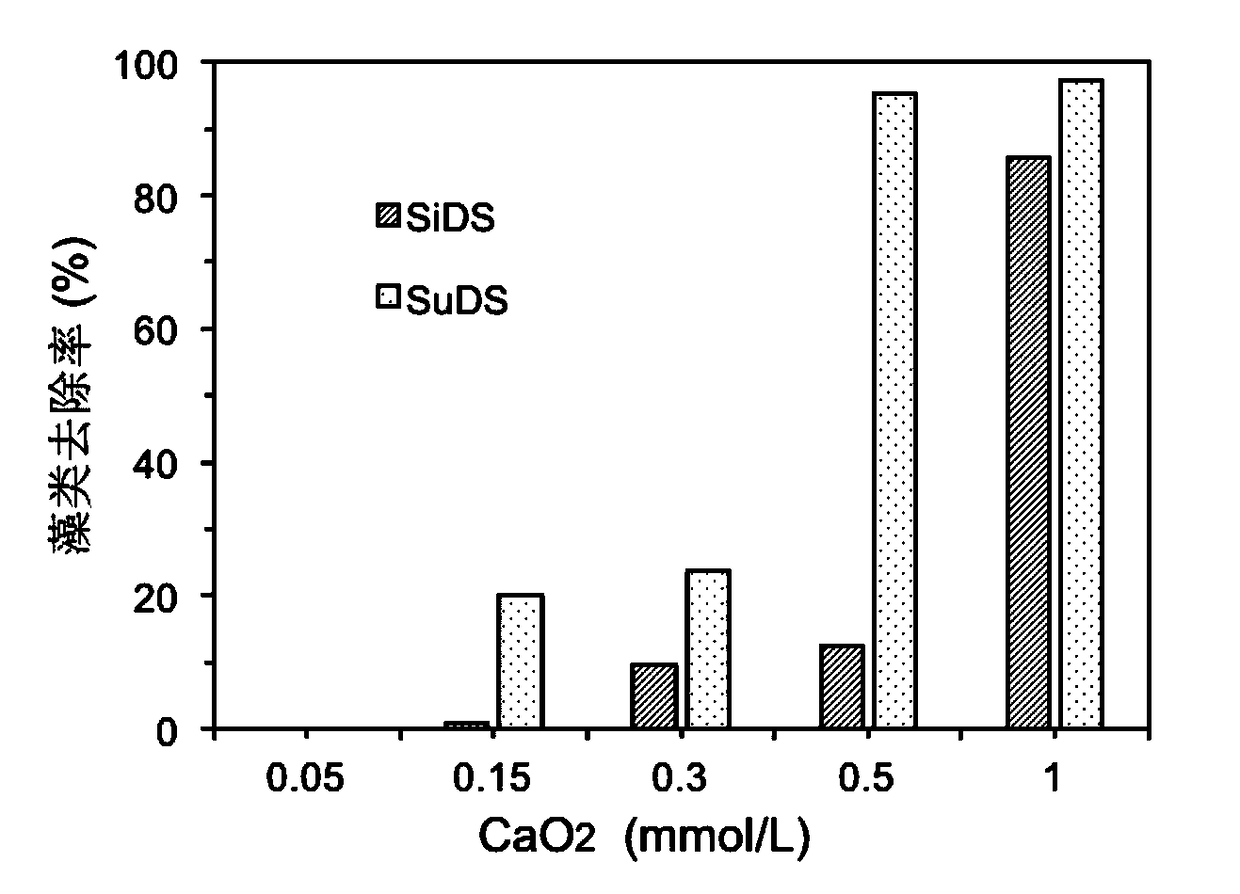

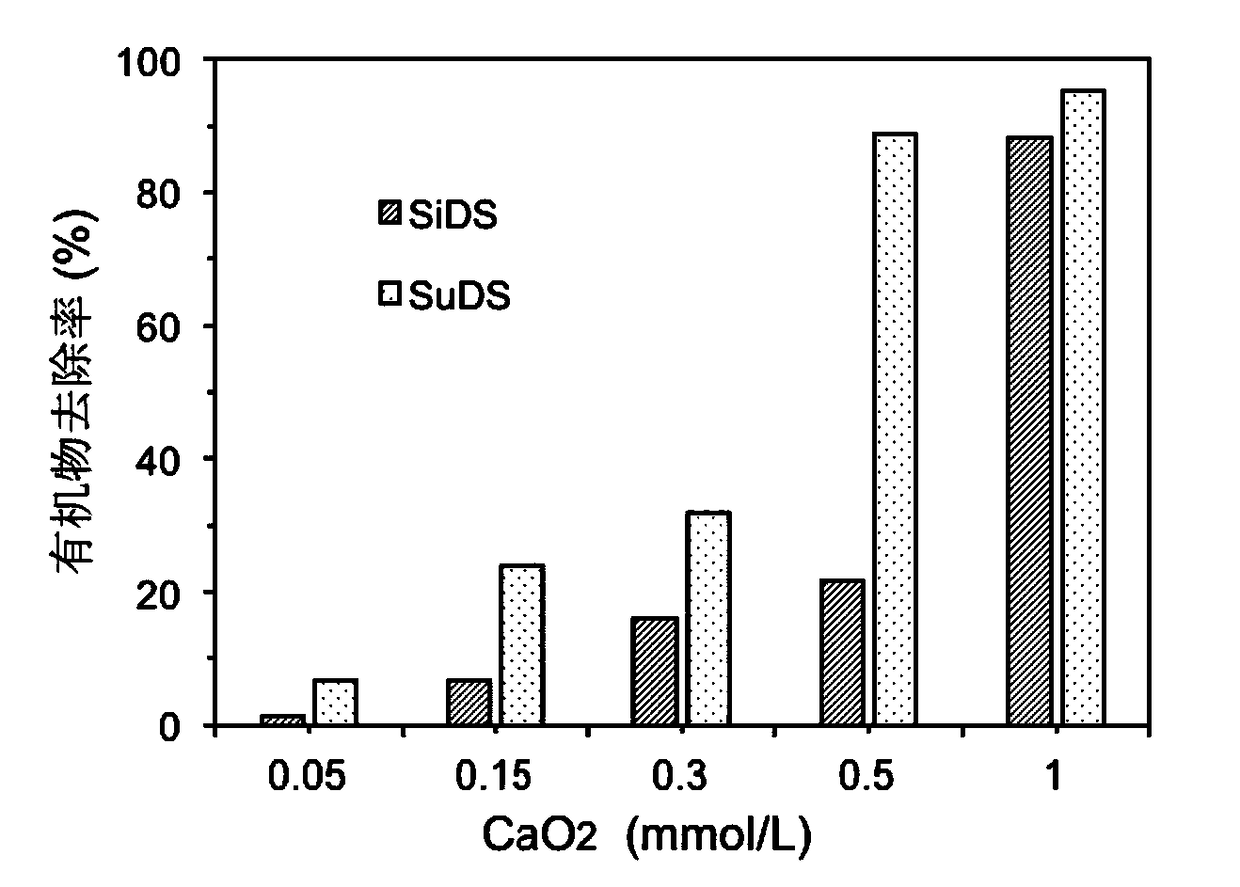

[0037] 2) Simultaneous addition of oxidant and coagulant experiment (SiDS): the configured CaO 2 The solution was added to the algae water according to the concentration gradient of 0.05, 0.15, 0.3, 0.5, 1.0mmol / L, and then immediately added 0.1mmol / L ferrous sulfate coagulant (15.2mg / L FeSO 4 ), simultaneously oxidizing and coagulating. First, stir rapidly under the condition of 200r / min for 2mins, then stir slowly under the condition of 50r / min for 15mins, and finally let it settle for 30mins, and take samples for testing.

[0038]3) Dosing the oxidant first and then adding the coagulant experiment (SuDS): the prepared CaO 2 The solution was added into the algae water according to the concentra...

Embodiment 3

[0041] Effect of calcium peroxide preoxidation enhanced coagulation on the integrity of algae cells

[0042] 1) Dilute Microcystis aeruginosa to about 2×10 with tap water 6 Algae / mL, respectively put into beakers to prepare for the experiment.

[0043] 2) The configured CaO 2 The solution was added into the algae water according to the concentration gradient of 0, 0.05, 0.15, 0.3, 0.5, 1.0mmol / L, fully stirred, and pre-oxidized for 30mins.

[0044] 3) Then add 0.1mmol / L ferrous sulfate coagulant (15.2mg / L FeSO 4 ) Coagulation. Firstly, coagulate quickly for 2mins under the condition of 200r / min, then coagulate for 15mins under the condition of 50r / min, and finally let it settle for 30mins, and take samples to measure K + .

[0045] the result shows( Figure 4 ), with CaO 2 Concentration increases, K + The concentration change is very small, indicating that calcium peroxide is a mild oxidant, which has little or no damage to the integrity of algae cells and will not cau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com