Hydrogen evolution reaction catalyst with layered mesoporous structure and preparation method of hydrogen evolution reaction catalyst

A technology of mesoporous structure and hydrogen evolution reaction, applied in the field of nanomaterials, can solve the problems of easy sample and reduced HER catalytic performance, and achieve the effects of low production cost, abundant electrochemical active sites, and broad industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 5.04g of oxalic acid, 2.52g of melamine, 0.6g of ammonium heptamolybdate tetrahydrate and 80ml of deionized water into a 150ml beaker, stir at 65°C for 6 hours in a water bath, then cool naturally to room temperature and add 20ml of deionized water to continue Stir for 12 hours, centrifuge to take the precipitate, wash the obtained precipitate repeatedly with absolute ethanol and deionized water, place it in a tube furnace, heat it up to 900°C at a rate of 2°C / min in a nitrogen atmosphere and keep it warm for 2 hours to obtain Carbon Nanomaterials A.

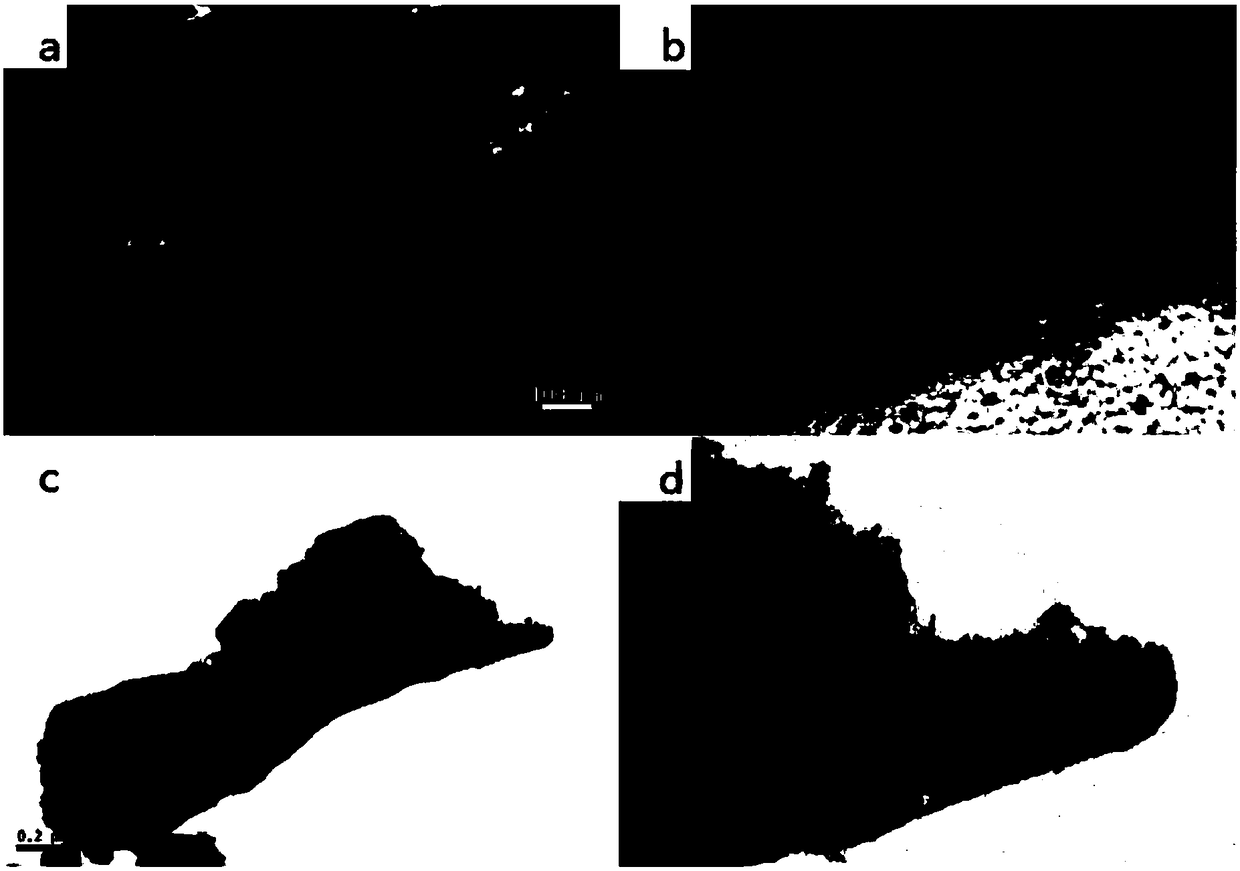

[0027] The obtained carbon nanomaterial A is observed with a scanning electron microscope and a transmission electron microscope, and the results are as follows figure 1 shown by figure 1 It can be seen that the microstructure of carbon nanomaterial A presents hierarchical mesopores.

Embodiment 2

[0038] Conduct electrocatalytic performance tests on carbon nanomaterials A-D and platinum carbon electrodes (pt / c), the test results are as follows Figure 5 As shown, carbon nanomaterial A has the best catalytic performance compared to platinum carbon electrode (pt / c) and carbon nanomaterials B, C and D.

[0039] After the carbon nanomaterial A was subjected to 2000 CV cycles, the electrocatalytic performance test was carried out, and the results were as follows: Figure 6 shown, from Figure 6 It can be seen that the sample still has high durability after 2000 CV cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com