Preparation method of bio-based composite adsorption material for sewage treatment

A composite adsorption material and sewage treatment technology, applied in the direction of adsorption of water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of excessive heavy metals in sludge, achieve improved hydrophobicity and good removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

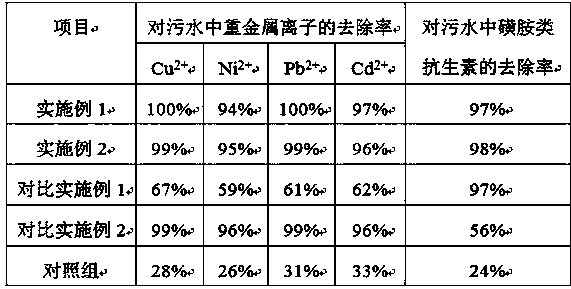

Examples

Embodiment 1

[0030] A method for preparing a bio-based composite adsorption material for sewage treatment, characterized in that it comprises the following steps:

[0031] (1) Organic modification of attapulgite:

[0032] Add hexadecyltrimethylammonium bromide to 5 parts of attapulgite according to the mass ratio of 1:20 and mix, then add 90 parts of absolute ethanol, ultrasonically vibrate for 1 hour, centrifuge and wash until there is no bromide ion, put in 100- Dry in an oven at 110°C, grind through a 200-mesh sieve, and obtain organically modified attapulgite;

[0033] (2) Preparation of calcium alginate cross-linked attapulgite-zeolite microspheres:

[0034] Add sodium alginate solution at a ratio of 1:10 to 15 parts of pretreated zeolite powder, then add organically modified attapulgite obtained in (1), mix and stir in a water bath stirrer at 35-45°C for 1 hour, and add calcium chloride solution dropwise , after continuing to stir for 8 hours, take it out to obtain calcium alginate...

Embodiment 2

[0046] A method for preparing a bio-based composite adsorption material for sewage treatment, characterized in that it comprises the following steps:

[0047] (1) Organic modification of attapulgite:

[0048]Add cetyltrimethylammonium bromide to 10 parts of attapulgite at a mass ratio of 1:20 and mix, then add 100 parts of absolute ethanol, ultrasonically vibrate for 2 hours, centrifuge and wash until there is no bromide ion, put in 100- Dry in an oven at 110°C, grind through a 200-mesh sieve, and obtain organically modified attapulgite;

[0049] (2) Preparation of calcium alginate cross-linked attapulgite-zeolite microspheres:

[0050] Add sodium alginate solution at a ratio of 1:10 to 20 parts of pretreated zeolite powder, then add organically modified attapulgite obtained in (1), mix and stir in a water bath stirrer at 35-45°C for 2 hours, and add calcium chloride solution dropwise , after continuing to stir for 10 hours, take it out to obtain calcium alginate cross-linke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com