Battery positive plate and manufacturing method thereof, and lithium ion battery and manufacturing method thereof

A battery positive electrode and battery negative electrode technology, which is applied in the manufacture of lithium-ion batteries and in the field of lithium-ion batteries, can solve the problems of small capacity of lithium-ion batteries, and achieve the effects of outstanding rate performance, improved adhesion, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] The preparation of the battery negative plate 3: first mix the suspending agent CMC dry powder and deionized water with a weight percentage of 2.0%wt to make a suspension agent glue with a solid content of 2.0%, and add graphite powder, 1.0% graphite powder, 1.0% by weight % conductive graphite and 2.0% SBR were mixed, then deionized water was added and mixed evenly to prepare a negative electrode slurry with a solid content of 50%. The negative electrode slurry is gap-coated on a metal copper foil with a thickness of 8 μm, dried at a temperature of 100-130 ° C, and then rolled into a second sheet with a thickness of about 130 μm. The design compaction density of the second sheet is Not higher than 1.7g / cm 3 , cut into long strips, the width of the cut piece is 96 mm, and the negative electrode tab 31 is welded at the gap foil to make the negative electrode sheet 3 of the battery.

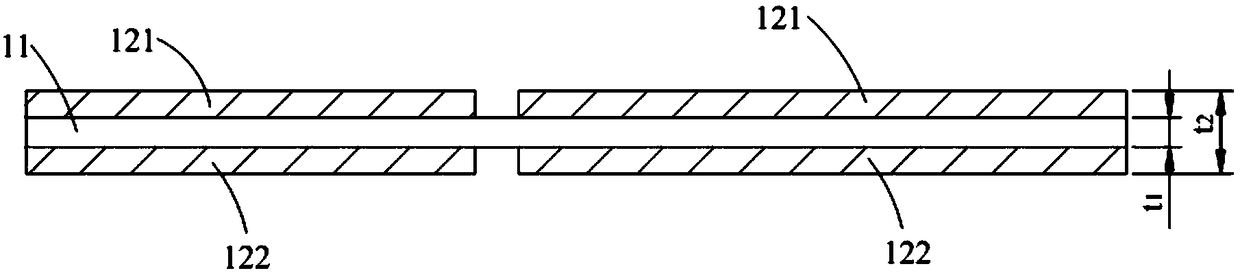

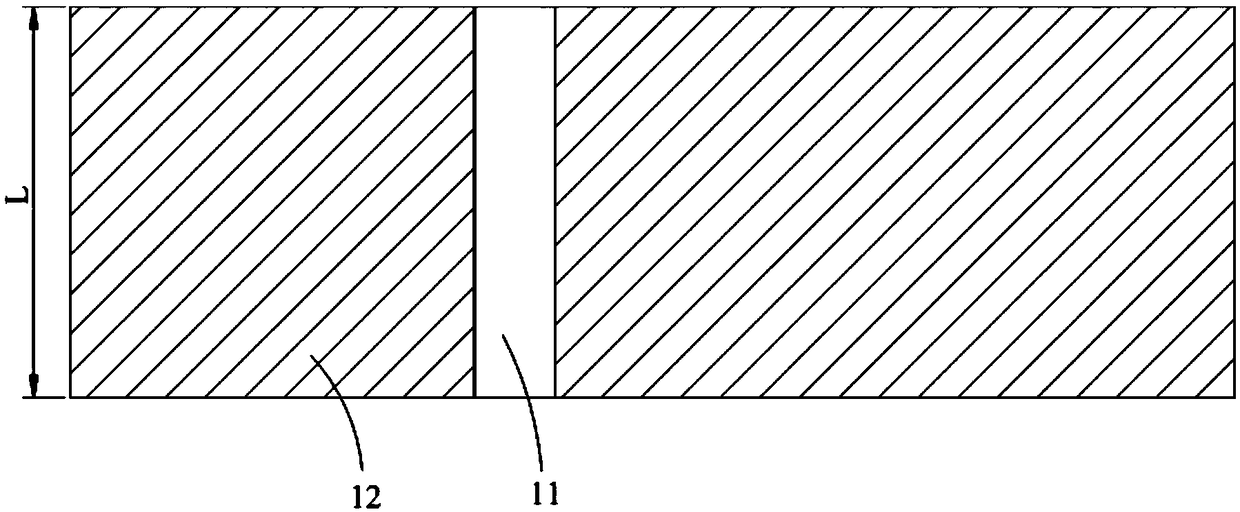

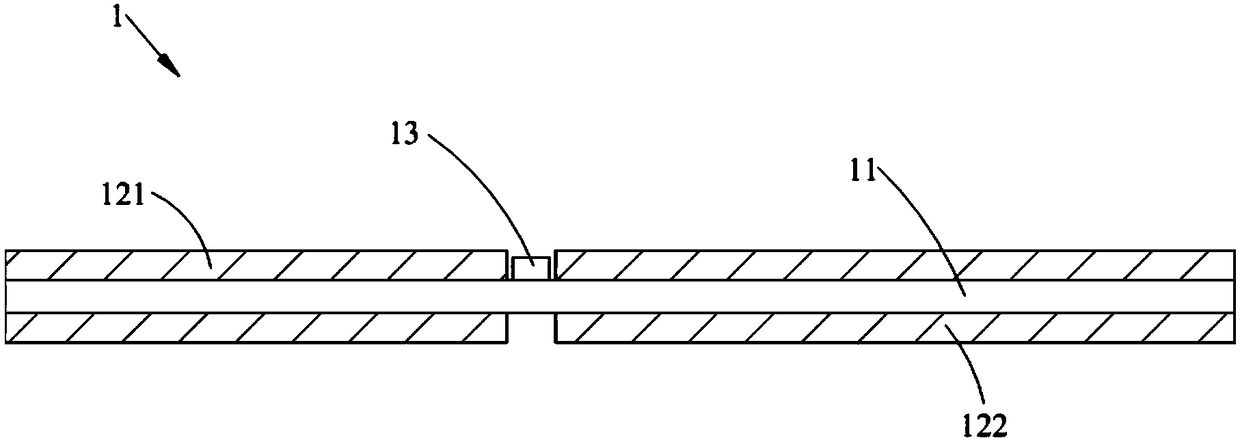

[0129] The preparation of battery positive electrode sheet 1: first mix the binder PVDF...

Embodiment 2

[0133] The preparation of the battery negative plate 3: first mix the suspending agent CMC dry powder and deionized water with a weight percentage of 2.2%wt to make a suspending agent glue with a solid content of 2.0%, and add a weight percentage of 94.8% graphite powder, 0.8 % conductive graphite and 2.2% SBR were mixed, then deionized water was added and mixed evenly to prepare negative electrode slurry with a solid content of 50%. The negative electrode slurry is gap-coated on a metal copper foil with a thickness of 8 μm. After drying at a temperature of 100-130° C., it is rolled into a second sheet with a thickness of about 126 μm. The design compaction density of the second sheet is not Higher than 1.7g / cm 3 . The second sheet was cut into long strips with a width of 96 mm, and the negative tab 31 was welded to the gap foil to make the battery negative sheet 3 .

[0134] The preparation of battery positive electrode sheet 1: first mix the binder PVDF dry powder of 2.1%w...

Embodiment 3

[0138] The preparation of the battery negative plate 3: first mix the suspending agent CMC dry powder and deionized water with a weight percentage of 2.4%wt to make a suspending agent glue with a solid content of 2.0%, and add a weight percentage of 94.5% graphite powder, 0.9 % conductive graphite and 2.2% SBR were mixed, then deionized water was added and mixed evenly to prepare negative electrode slurry with a solid content of 50%. The negative electrode slurry is gap-coated on a metal copper foil with a thickness of 8 μm. After drying at a temperature of 100-130° C., it is rolled into a second sheet with a thickness of about 123 μm. The design compaction density of the second sheet is not Higher than 1.7g / cm 3 . The second sheet was cut into long strips with a width of 96 mm, and the negative tab 31 was welded to the gap foil to make the battery negative sheet 3 .

[0139] The preparation of battery positive sheet 1: first mix the binder PVDF dry powder of 2.3%wt by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com