Multi-layer mesh current collector of lithium ion battery and manufacturing method of multi-layer mesh current collector

A lithium ion battery and manufacturing method technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problem of low tensile strength of two-dimensional flat foils, easy to break the production efficiency of enterprises, limit lithium Electronic battery energy density and other issues, to achieve the effect of improving electrochemical performance, reducing internal resistance, and increasing the amount of dressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

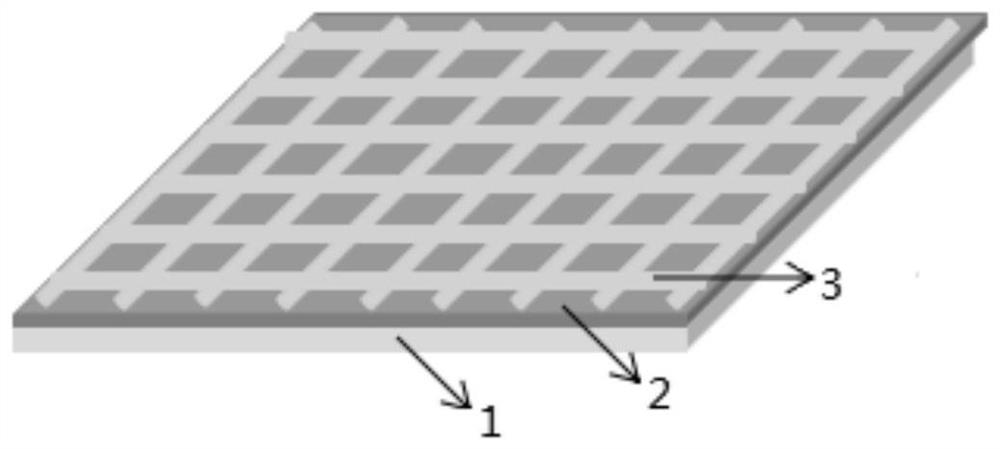

[0025] A multilayer mesh current collector for a lithium ion battery, comprising a substrate, an adhesive layer arranged on both sides of the substrate, and a mesh current collector layer connected to the surface of the adhesive layer, wherein the substrate is a PET film, the adhesive The adhesive layer is cured by PVDF adhesive. The mesh current collector layer is composed of mesh aluminum current collector with a mesh number of 50. The thickness of the substrate is 8 μm, the thickness of the adhesive layer is 1 μm, and the mesh current collector layer. The thickness is 20 μm.

[0026] The manufacturing method of the above-mentioned lithium-ion battery multilayer mesh current collector comprises:

[0027] S1. Apply the adhesive on both sides of the substrate by printing and coating with an anilox roller, dry and solidify in a suspension oven to form an adhesive layer, wherein the adhesive is composed of PVDF and solvent NMP in a mass ratio of 1:11.5;

[0028] S2. Hot-pressin...

Embodiment 2

[0031] A multilayer mesh current collector for a lithium ion battery, comprising a substrate, an adhesive layer arranged on both sides of the substrate, and a mesh current collector layer connected to the surface of the adhesive layer, wherein the substrate is a PET film, the adhesive The adhesive layer is cured by PVDF adhesive. The mesh current collector layer is composed of mesh copper current collector with a grid mesh number of 50. The thickness of the substrate is 8 μm, the thickness of the adhesive layer is 1 μm, and the mesh current collector layer The thickness is 20 μm.

[0032] The manufacturing method of the above-mentioned lithium-ion battery multilayer mesh current collector comprises:

[0033] S1. Apply the adhesive on both sides of the substrate by printing and coating with an anilox roller, dry and solidify in a suspension oven to form an adhesive layer, wherein the adhesive is composed of PVDF and solvent NMP in a mass ratio of 1:11.5;

[0034] S2. Hot-press...

Embodiment 3

[0037] A lithium-ion battery comprising a positive electrode sheet, a negative electrode sheet, a diaphragm, an electrolyte and a casing, wherein the positive electrode sheet includes the multilayer mesh current collector in Example 1 and the active positive electrode coated on the above-mentioned multilayer mesh collector Materials; the negative electrode sheet includes the multilayer mesh current collector in Example 2 and the negative electrode active material coated on the multilayer mesh current collector.

[0038] Among them, the positive electrode active material is composed of lithium iron phosphate, binder and conductive agent, wherein the binder is PVDF, and the conductive agent is composed of superconducting carbon black (SP) and graphene. According to the mass ratio, lithium iron phosphate: SP : Graphene: PVDF=96.8:0.7:0.5:2.0; Negative electrode active material is made up of artificial graphite, thickener, binding agent and conductive agent, and wherein thickener i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com