Battery positive sheet, manufacturing method of battery positive sheet, lithium ion battery, and manufacturing method of lithium ion battery

A battery positive and negative electrode technology, applied in the direction of battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problems of small capacity of lithium-ion batteries, and achieve the effects of reducing resistance, increasing the amount of dressing, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] Preparation of battery negative electrode sheet 3: mix 1.5%wt of suspending agent dry powder, 94.5%wt of graphite powder, 2.0%wt of negative electrode conductive agent, and 2.0%wt of negative electrode binder, then add deionized water and mix evenly to make a solid Negative electrode slurry with a content of 50% is intermittently coated on a metal copper foil with a thickness of 8 μm, dried at a temperature of 100°C-130°C, rolled into a second sheet with a thickness of about 130 μm, and cut into long strips shape, the width of the cut sheet is 66.5mm, and the negative electrode tab 31 is welded at the gap foil to make the negative electrode sheet 3 of the battery.

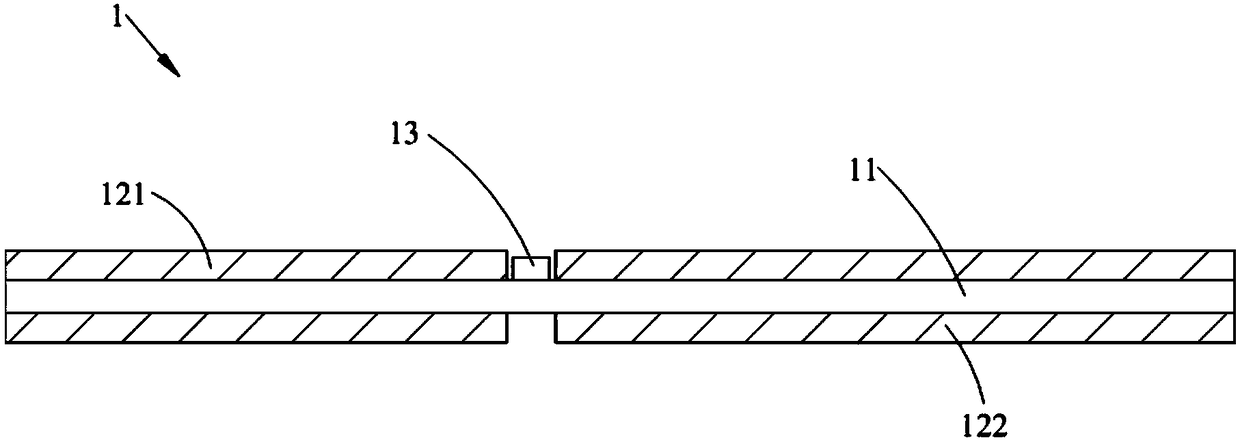

[0135] Preparation of battery positive sheet 1: 2.0%wt of positive electrode binder dry powder, 3.0%wt of positive electrode conductive agent (wherein, 1.0%wt of granular positive electrode conductive agent, 2.0%wt of fibrous positive electrode conductive agent), 95.0% of positive electrode active material w...

Embodiment 2

[0139]Preparation of battery negative electrode sheet 3: mix suspending agent dry powder 1.4%wt, graphite powder 94.6%wt, conductive agent 2.1%wt, negative electrode binder 1.9%wt, add deionized water and mix evenly to make solid content It is a 48% negative electrode slurry, which is intermittently coated on a metal copper foil with a thickness of 8 μm. After drying at a temperature of 100°C-130°C, it is rolled into a second electrode sheet with a thickness of about 125 μm and cut into long strips. , the width of the cut sheet is 66.5mm, and the negative tab 31 is welded at the gap foil to make the negative electrode sheet 3 of the battery.

[0140] The preparation of positive electrode sheet 1 of the battery: dry powder of positive electrode binder 1.8%wt, positive electrode conductive agent 2.5%wt (wherein, granular positive electrode conductive agent 1.0%wt, fibrous positive electrode conductive agent 1.5%wt), positive electrode active material 95.7% Wt and an appropriate ...

Embodiment 3

[0144] The preparation of battery negative plate 3: mix 1.6%wt of suspending agent dry powder, 94.2%wt of graphite powder, 2.2%wt of negative electrode conductive agent, 2.0%wt of negative electrode binder, then add deionized water and mix evenly to make a solid The negative electrode slurry with a content of 52% is intermittently coated on a metal copper foil with a thickness of 8 μm. After drying at a temperature of 100°C-130°C, it is rolled into a second sheet with a thickness of about 135 μm and cut into strips shape, the width of the sheet body cut out is 66.5 mm, and the negative electrode tab 31 is welded at the gap foil to make the negative electrode sheet 3 of the battery.

[0145] The preparation of positive electrode sheet 1 of the battery: dry powder of positive electrode binder 2.2%wt, positive electrode conductive agent 2.5%wt (wherein, granular positive electrode conductive agent 0.8%wt, fibrous positive electrode conductive agent 1.7%wt), positive electrode acti...

PUM

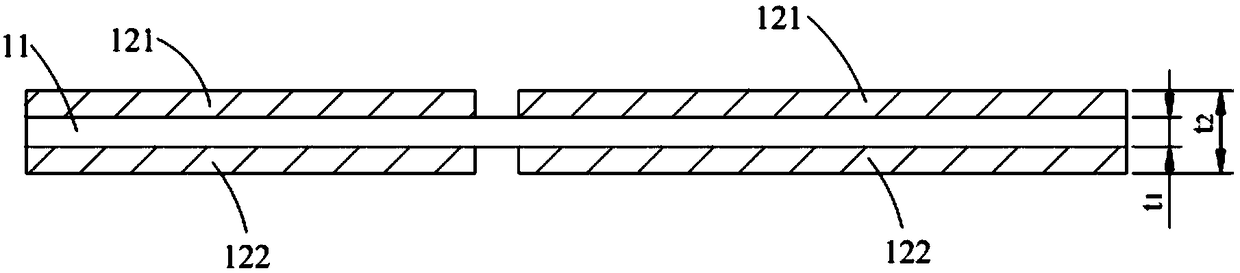

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com