Battery cathode plate, method of manufacturing same, lithium ion battery, and method of manufacturing same

A technology of battery positive electrode and battery negative electrode, which is applied in the manufacture of electrolyte batteries, battery electrodes, electrode carriers/current collectors, etc., can solve the problems of small capacity of lithium ion batteries, and achieve outstanding rate performance, reliable safety performance, and increase the amount of dressing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] The preparation of the battery negative plate 3: first mix the suspending agent CMC dry powder and deionized water with a weight percentage of 1.5%wt to make a suspension agent glue with a solid content of 1.5%, and add 94.8% graphite powder, 1.5% by weight % conductive graphite and 2.2% SBR were mixed, then deionized water was added and mixed evenly to prepare negative electrode slurry with a solid content of 50%. The negative electrode slurry is gap-coated on a metal copper foil with a thickness of 8 μm. After drying at a temperature of 100-130° C., it is rolled into a second sheet with a thickness of about 111 μm. The design compaction density of the second sheet is Not higher than 1.7g / cm 3 , cut into long strips, the width of the cut piece is 66.5mm, and the negative electrode tab 31 is welded at the gap foil to make the negative electrode sheet 3 of the battery.

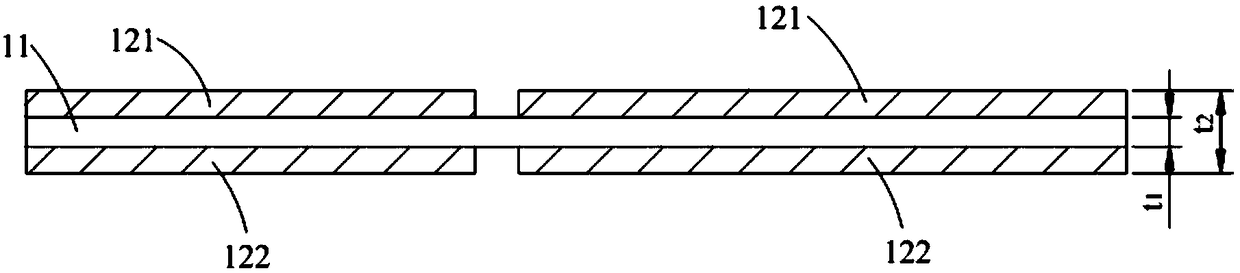

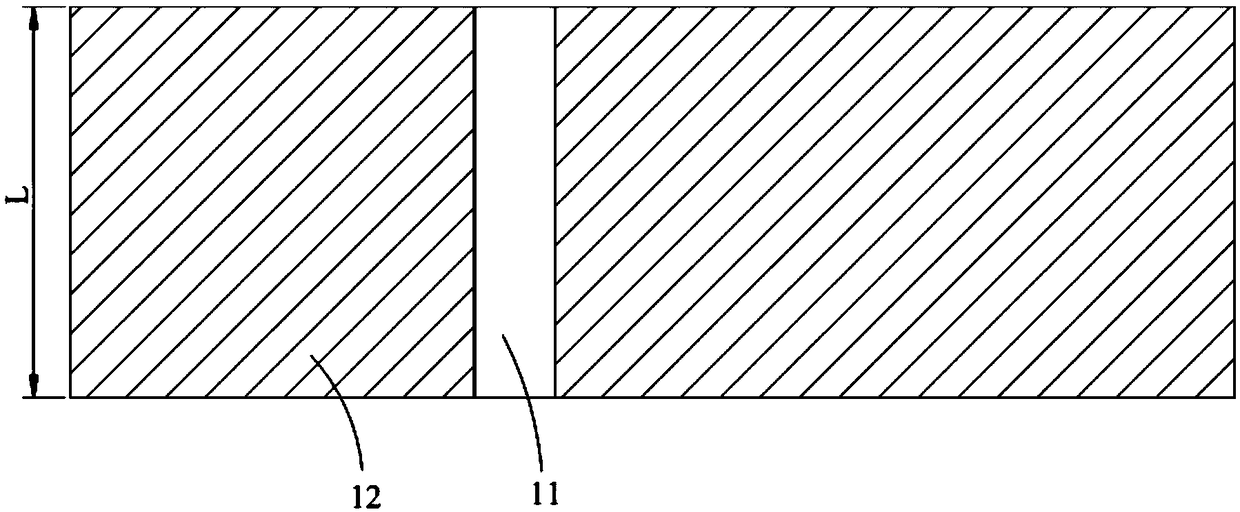

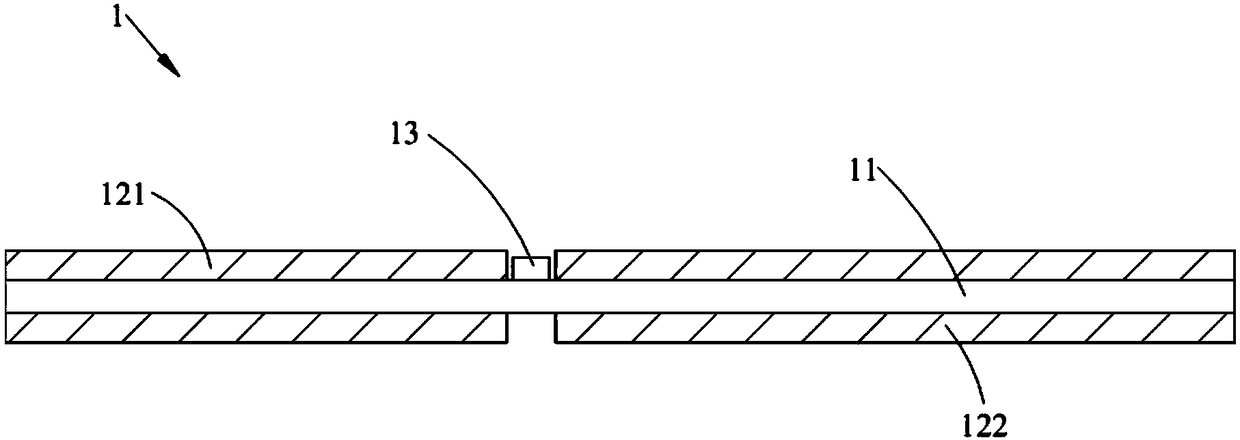

[0129] The preparation of battery positive sheet 1: first mix the binder PVDF dry powder of 3.0%wt b...

Embodiment 2

[0133] The preparation of the battery negative plate 3: first mix the suspending agent CMC dry powder and deionized water with a weight percentage of 1.8%wt to make a suspension agent glue with a solid content of 1.5%, and add a weight percentage of 95.2% graphite powder, 1.0 % conductive graphite and 2.0% SBR were mixed, then deionized water was added and mixed evenly to prepare a negative electrode slurry with a solid content of 48%. The negative electrode slurry is gap-coated on a metal copper foil with a thickness of 8 μm, dried at a temperature of 100-130° C., and then rolled into a second sheet with a thickness of about 115 μm. The design compaction density of the second sheet is not Higher than 1.7g / cm 3 . The second sheet was cut into long strips with a width of 66.5 mm, and the negative tab 31 was welded to the gap foil to make the battery negative sheet 3 .

[0134] The preparation of battery positive sheet 1: first mix the binder PVDF dry powder of 2.8%wt by weigh...

Embodiment 3

[0138] The preparation of the battery negative plate 3: first mix the suspending agent CMC dry powder and deionized water with a weight percentage of 2.0%wt to make a suspending agent glue with a solid content of 1.5%, and add a weight percentage of 95.4% graphite powder, 0.8 % conductive graphite and 1.8% SBR were mixed, then deionized water was added and mixed evenly to prepare a negative electrode slurry with a solid content of 49%. The negative electrode slurry is gap-coated on a metal copper foil with a thickness of 8 μm, dried at a temperature of 100-130° C., and then rolled into a second sheet with a thickness of about 116 μm. The design compaction density of the second sheet is not Higher than 1.7g / cm 3 . The second sheet was cut into long strips with a width of 66.5 mm, and the negative tab 31 was welded to the gap foil to make the battery negative sheet 3 .

[0139] The preparation of battery positive electrode sheet 1: first mix the binder PVDF dry powder of 2.8%w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com