A liquid polymer shrinkage reducing and compacting agent for concrete

A polymer and concrete technology, applied in the field of liquid polymer shrinkage reducing and compacting agent for concrete, can solve the problems of difficult promotion and high price, achieve good social and economic benefits, low cost, and improve the effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

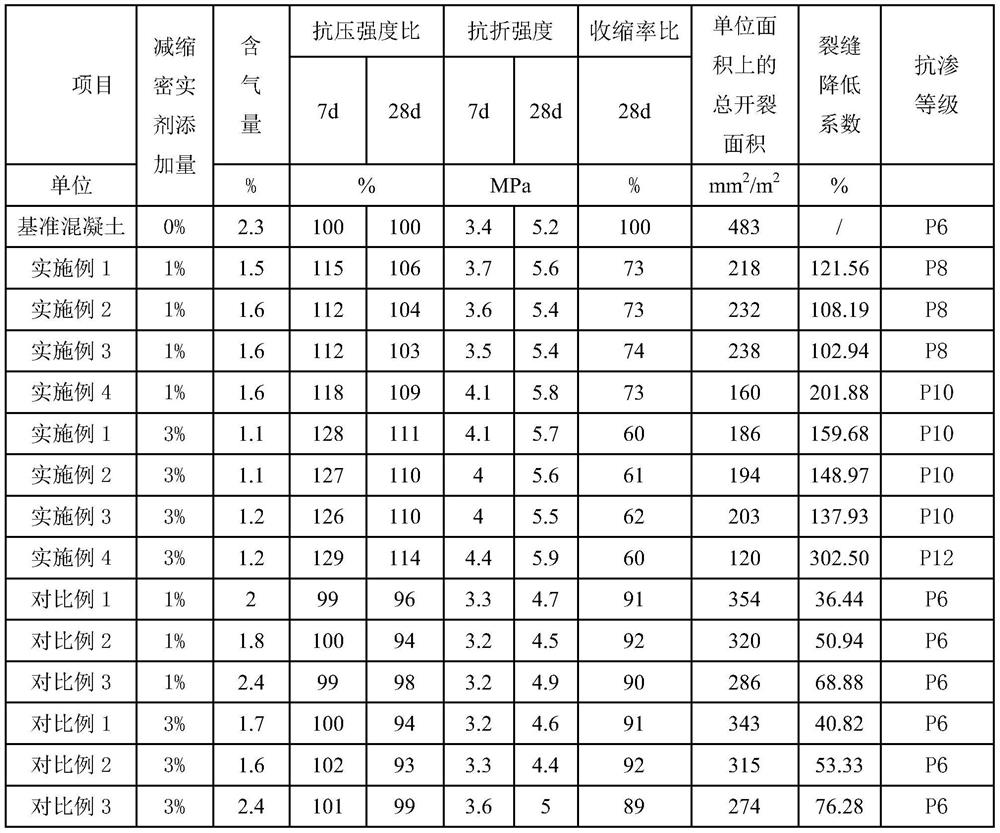

Examples

Embodiment 1

[0038] The liquid macromolecule shrinkage reducing and compacting agent for concrete of the present embodiment is composed of the following raw materials in terms of mass percentage: a concentration of 99% triethanolamine 1.2%, a concentration of 85% triisopropanolamine 1.5%, anhydrous sodium sulfate 3%, sodium tripolyphosphate 2%, polysiloxane 0.2%, polyether 0.3%, tert-butanol 0.1%, and the rest is water. The preparation method is firstly dissolving the solid components in water, then adding other components and stirring evenly to obtain a clear liquid polymer shrinkage reducing and compacting agent.

Embodiment 2

[0040] The liquid macromolecule shrinkage-reducing compacting agent of the present embodiment, by mass percent, is made up of following raw material: 85% triethanolamine 1.5, 85% triisopropanolamine 1.2, anhydrous sodium sulfate 4.5, sodium tripolyphosphate 4.0, Polysiloxane 0.4, polyether 0.2, tert-butanol 0.3, and the rest is water. The preparation method is firstly dissolving the solid components in water, then adding other components and stirring evenly to obtain a clear liquid polymer shrinkage reducing and compacting agent.

Embodiment 3

[0042] The liquid macromolecule shrinkage reducing and compacting agent for concrete of the present embodiment is composed of the following raw materials in terms of mass percentage: a concentration of 85% triethanolamine 1.5%, a concentration of 85% triisopropanolamine 1.2%, anhydrous sodium sulfate 3%, sodium tripolyphosphate 2%, polysiloxane 0.2%, polyether 0.2%, tert-butanol 0.2%, and the rest is water. The preparation method is firstly dissolving the solid components in water, then adding other components and stirring evenly to obtain a clear liquid polymer shrinkage reducing and compacting agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com