Velvet matte lip glaze and preparation method thereof

A matte and lip gloss technology, which is applied in pharmaceutical formulas, cosmetic preparations, dressing preparations, etc., can solve problems such as unnatural makeup, affecting product quality, and product instability, achieving a good soft-focus effect and reducing Good skin feeling and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

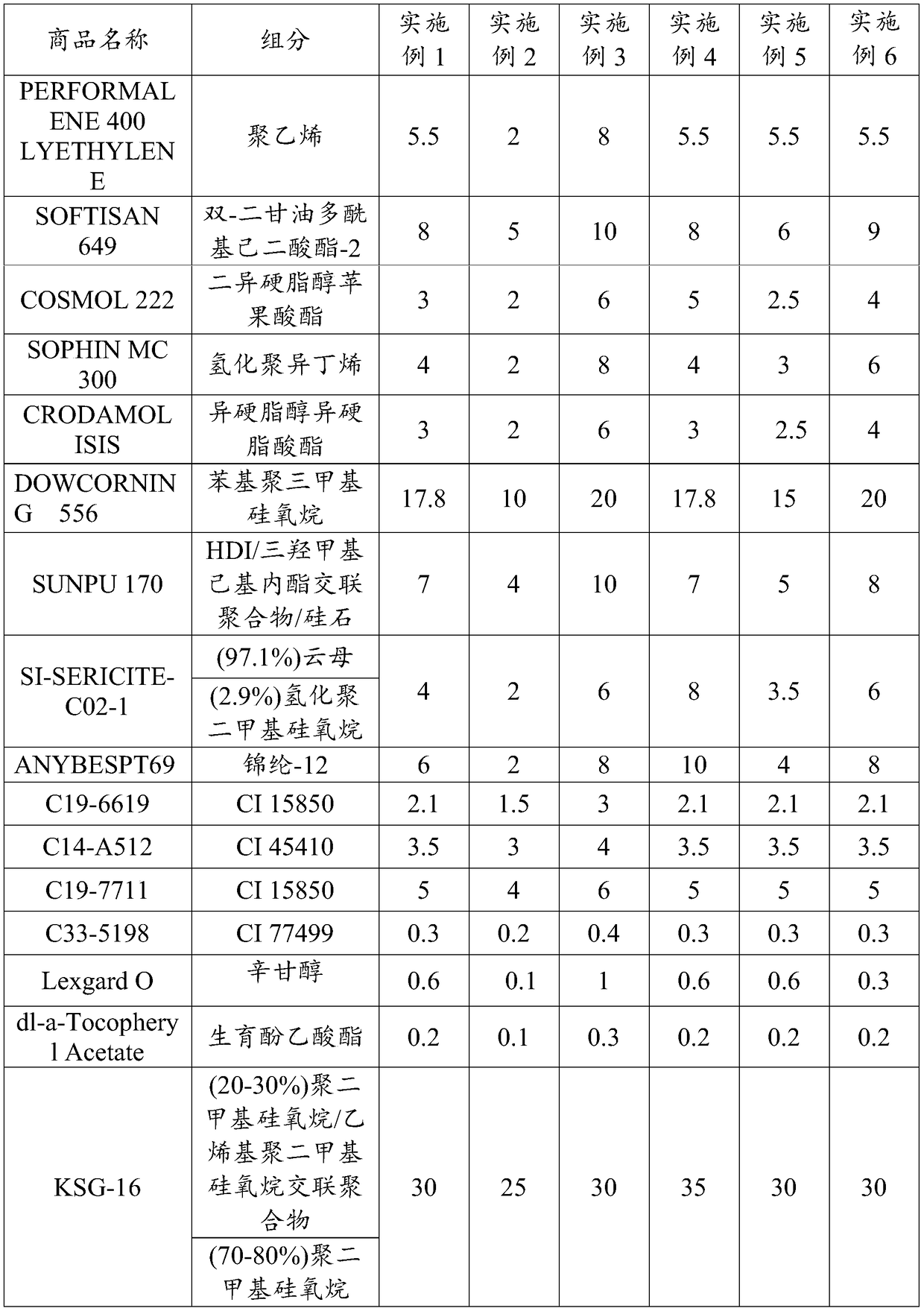

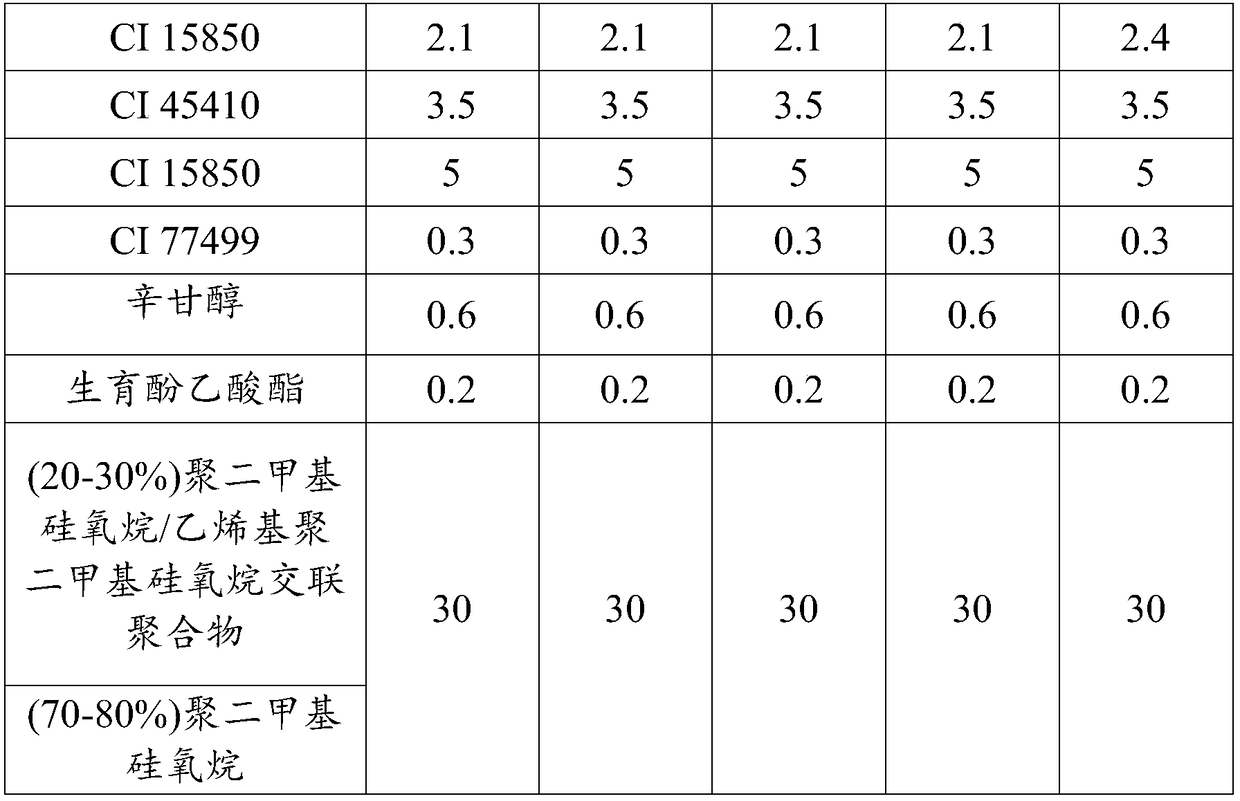

[0021] Embodiments 1 to 6 are examples of the velvet matte lip glaze of the present invention, and the weight content formula of the velvet matte lip glaze of embodiments 1 to 6 is shown in Table 1:

[0022] Table 1 embodiment 1~6 the weight content formula of velvet matte lip glaze

[0023]

[0024] The preparation method of the velvet matte lip glaze of the present invention comprises the following steps: 1) mixing polyethylene, bis-diglycerol polyacyl adipate-2, diisostearyl malate, hydrogenated polyisobutylene, and isohard Add aliphatic alcohol isostearate into the heating mixing barrel, start stirring at 50-100 rpm, and heat up to 90-95 degrees; 2) After the material body is completely dissolved, cool down to 70-75 degrees, add KSG-16, benzene base polytrimethicone, adjust and stir to 100-150 rpm; 3) add caprylyl glycol and tocopheryl acetate after the dispersion is complete, and stir for 5-10 minutes; 4) mix HDI / trimethylol Caprylactone Crosspolymer / Silica, 97.1% Mic...

Embodiment 7

[0030] Example 7 Velvet Matte Lip Glaze Effect Test

[0031] The velvet matte lip glaze prepared by Examples 1-6 of the present invention, Comparative Examples 1-5, and commercially available products was tested for glossiness

[0032] Test samples: samples of Examples 1-6 and samples of Comparative Examples 1-5.

[0033] Test instrument: Linshang LS192 gloss meter, used to test the gloss of the sample.

[0034] Test method: The test sample is evenly coated in an opaque smooth flat cardboard. The coated area is 10 cm x 10 cm.

[0035] The number of tests: each group was tested 5 times in the coating area (four end points and the central position), and the average value was taken.

[0036] Evaluation method: By measuring the coated areas of different samples and comparing the difference in gloss, the lower the gloss, the stronger the matte effect.

[0037] The test results are shown in Table 3:

[0038] Gloss test of table 3 embodiment 1~6 and comparative examples 1~5 and ...

Embodiment 8

[0042] The smearability, smoothness, and dryness of the lip glazes of Examples 1-6 and Comparative Examples 1-5 were evaluated.

[0043] Evaluation method: 330 people, 10 professional evaluators for each embodiment, conducted the use test. Each evaluator applied each sample to the lips, and scored according to the absolute evaluation of the following grades. The scores of all the evaluators were summed up, the average value was calculated, and judgment was made according to the following grade judgment criteria. It should be noted that, for the evaluation items of makeup effect applicability, smoothness, and drying degree, the sample is applied to the lips. After the evaluators go through normal life, after using it for 8 hours, try it twice a day for 1 week Then evaluate.

[0044] Evaluation items: spreadability, smoothness, and dryness.

[0045] Grade Absolute Evaluation Rating:

[0046] Very good: 10 points; Good: 8 points; Slightly better: 6 points; Fair: 4 points; Poor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com