Self-expanding foot locking anchor pipe

A lock-foot anchor pipe and self-expanding technology, which is applied in the installation of anchor rods, wellbore linings, tunnel linings, etc., can solve problems such as early excavation and early support of tunnels, unclear force transmission effects, and air quality impacts. Achieve the effect of low installation technical threshold, improved installation tolerance and pre-tightening, and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

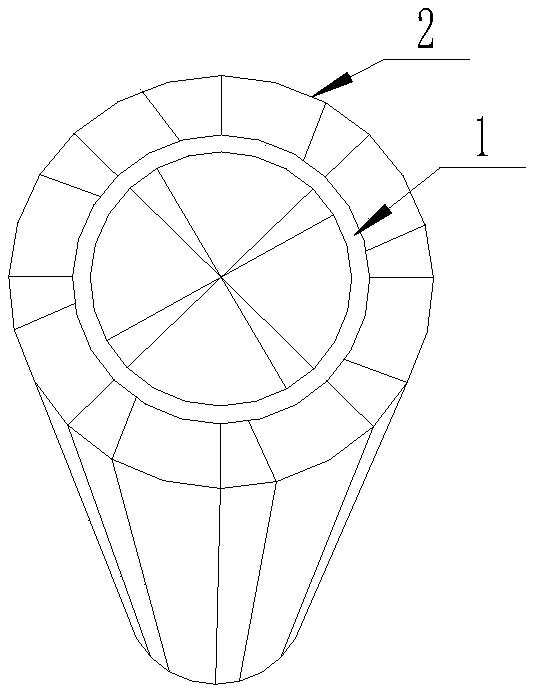

[0036] Such as Figure 1-5 The shown self-expanding locking foot anchor tube, a self-expanding locking foot anchor tube, is characterized in that it includes:

[0037] anchor pipe 1;

[0038] The storage bag 2, the storage bag 2 is in contact with the anchor tube 1;

[0039] The storage bag breaking mechanism is used to break the storage bag 2 .

[0040] In actual use, according to the design dimensions of different anchor pipes 1, a hole slightly larger than the diameter of the anchor pipe is drilled on the surrounding rock by wind or water, and a storage bag is installed on the prefabricated anchor pipe with a storage bag damage mechanism. After the storage bag is installed, insert the self-expanding anchor tube into the formed hole, use the storage bag damage mechanism to break the storage bag 2, stimulate the self-expanding concrete to mix with the expansion activator, and fix the locking tube on the surrounding rock In the drill hole, the anchor pipe is fixedly connect...

Embodiment 2

[0043] Such as Figure 1-5 The self-expanding locking foot anchor tube shown is different from the first embodiment in that: the outer wall of the anchor tube 1 is covered with a storage bag 2; between the storage bag 2 and the anchor tube 1 is The storage bag damage mechanism, the end of the anchor tube 1 is provided with a storage bag damage mechanism driver.

[0044] Preferably, the storage bag damage mechanism is a cutting piece 8, and the cutting piece 8 is fixedly connected on the outer wall of the anchor pipe 1; the described cutting pieces 8 are in multiple groups, and each cutting piece 8 is evenly spaced and fixedly connected to the outer wall of the anchor pipe 1 Above; the sheet-like lower bottom edge of the cut sheet 8 is fixedly connected with the outer wall of the anchor pipe 1, the sheet-shaped upper bottom edge of the cut sheet 8 is a blunt edge, the two sides of the cut sheet 8 are sharp edges, and the cut sheet 8 The ratio of the thickness to the diameter o...

Embodiment 3

[0049] Such as Figure 1-5 The self-expanding locking foot anchor pipe shown is different from the second embodiment in that: the screw part is a threaded sleeve 4; one end of the threaded sleeve 4 is connected to the other end of the first threaded rod 3 One end is connected through a matching thread; the other end of the threaded sleeve 4 is connected with one end of the second threaded rod 5 through a matching thread, and the other end of the second threaded rod 5 is fixedly connected with one end of the connecting rod 9 through a universal joint 6 , the other end of the connecting rod 9 is connected with an arch fixed connection end plate 7; the arch fixed connection end plate 7 is a rectangular steel plate; four corners of the rectangular arch fixed connection end plate 7 are provided with bolts connected vias.

[0050] In actual use, after the prefabricated anchor pipe with the storage bag damage mechanism and the surrounding rock are fixed and installed, the arch frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com