Method for preparing metal cladding high-temperature phase change heat storage microcapsule and heat storage microcapsule obtained by method

A technology of high-temperature phase change and metal phase change, which is applied in the field of heat storage microcapsules and the preparation of metal-shelled high-temperature phase change heat storage microcapsules, can solve the problems of single application and unrealization, and achieve good thermal cycle performance and high yield High, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

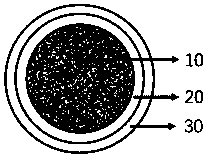

[0023] This embodiment provides a metal-clad high-temperature phase-change heat storage microcapsule, the structure of which is as follows: figure 1 As shown, it includes an iron ball core 10, zirconium as the inner cladding 20, and tungsten as the outer cladding 30, and the specific preparation steps include:

[0024] S1, core preparation: select an iron ball with a diameter of 500 μm as the core. After ultrasonic cleaning with acetone, deionized water and ethanol, the iron ball core 10 is obtained by drying in a drying oven.

[0025] S2, put a certain number of iron ball cores 10 into the reaction tube of the high-temperature fluidized bed chemical vapor deposition device, use argon as the carrier gas, and raise the temperature to a set temperature of 1500°C.

[0026] S3, inner layer (zirconium layer) preparation: switch fluidization gas to argon, hydrogen and zirconium chloride (ZrCl 4 ) steam, and continue to coat for one hour to obtain the inner layer cladding 20 of zir...

Embodiment 2

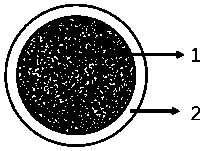

[0030] This embodiment provides another metal-clad high-temperature phase-change heat storage microcapsule, the structure of which is as follows: figure 2 As shown, it includes a copper ball core 1 and a niobium cladding 2 . Concrete preparation steps include:

[0031] S1, core preparation: a copper ball with a diameter of 500 μm is selected as the core. After being ultrasonically cleaned with acetone, deionized water and ethanol, the copper ball core 1 was obtained by drying in a drying oven.

[0032] S2, put a certain number of copper ball cores 1 into the reaction tube of the high-temperature fluidized bed chemical vapor deposition device, use argon as the carrier gas, and raise the temperature to a set temperature of 850°C-1000°C.

[0033] S3, preparation of niobium layer: switch fluidization gas to argon, hydrogen and niobium chloride (NbCl 5 ) steam, and continue coating to obtain the niobium cladding 2 coated on the copper ball core 1.

[0034] S4, cooling and unload...

Embodiment 3

[0037] This embodiment provides yet another metal-shelled high-temperature phase-change heat storage microcapsule, and the specific preparation steps include:

[0038] S1, core preparation: a copper ball with a diameter of 500 μm is selected as the core. After ultrasonic cleaning with acetone, deionized water and ethanol, the copper ball core was obtained by drying in a drying oven.

[0039] S2, put a certain number of copper ball cores into the reaction tube of the high-temperature fluidized bed chemical vapor deposition device, use argon as the carrier gas, and raise the temperature to a set temperature of 400°C.

[0040] S3, preparation of tungsten layer: switch fluidization gas to argon, hydrogen and tungsten carbonyl W(CO) 6 , and continued to deposit for two hours.

[0041] S4, cooling and unloading: switch the gas of the high-temperature fluidized bed chemical vapor deposition device to argon, cool down to room temperature, and unload.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com