Spherical covalent organic framework material as well as preparation method and application thereof

A covalent organic framework and spherical technology, applied in the field of chromatographic materials, can solve the problems of pure spherical COFs materials that have not been reported, and achieve good application prospects, expand the pH application range, and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

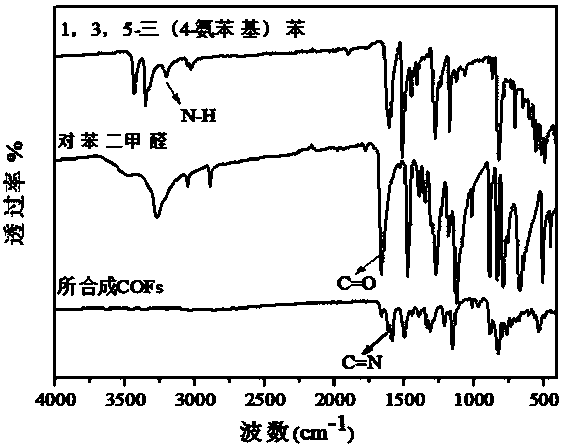

[0026] Disperse 32.4 mg (0.24 mmol) terephthalaldehyde (, 56.2 mg (0.16 mmol) 1,3,5-tris(4-aminophenylbenzene) homogeneously in 25 mL (0.43 mol) of absolute ethanol at room temperature Ultrasonic to make it uniformly dispersed, then quickly add 2 mL of 6mol / L acetic acid, and then ultrasonic for 3 minutes, then let stand at room temperature for 24 hours to obtain a spherical covalent organic framework material. The resulting material was added to a Soxhlet extractor and extracted with tetrahydrofuran After reflux washing for 24 hours, centrifugation and washing with ethanol for several times, they were dried in a vacuum oven at 120 °C for 24 hours.

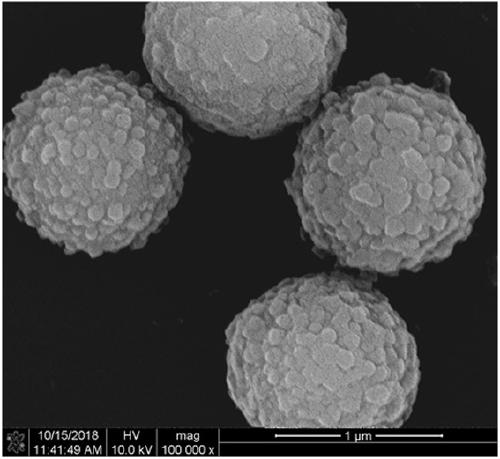

[0027] figure 1 It is a scanning electron micrograph of the spherical covalent organic framework material obtained in Example 1. It can be clearly seen from the figure that the particle size of the spherical covalent organic framework material is uniform, and the size is about 1 μm.

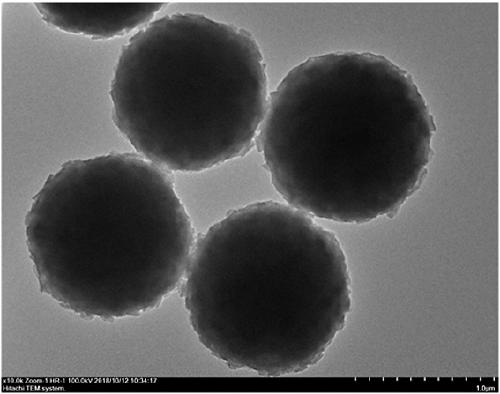

[0028] figure 2 It is a transmission elect...

Embodiment 2

[0033] The spherical covalent organic framework material prepared in Example 1 was used as a chromatographic stationary phase, and filled into an empty stainless steel short column with an inner diameter of 2.1 mm and a length of 50 mm by a dry filling method (stainless steel short columns need to be filled in sequence before filling). Ultrasonic cleaning several times with acetone and ethanol). When loading the column, one end of the empty column is tightened and connected to a vacuum source, and the other end is equipped with a funnel, and the dry spherical covalent organic framework material is slowly added to it, and the column wall is gently tapped from all directions to make the material fall into the column. After the filling is completed, the mobile phase (acetonitrile:water=90:10, v:v) with a flow rate of 0.5 mL / min is used to wash and balance for a long time on the high-performance liquid chromatograph to obtain a tightly packed and uniform chromatographic column. Fi...

Embodiment 3

[0036] In liquid chromatography (HPLC) mode, water was used as mobile phase A, acetonitrile was used as mobile phase B, and the chromatographic conditions were 55% B; the pump flow rate was 0.5 mL / min, and the detection wavelength was 214 nm; the determination of thiourea (10 ppm ) and toluene (50 ppm), ethylbenzene (50 ppm), propylbenzene (50 ppm) single sample and mixed sample on the chromatographic column prepared in embodiment 2 separation situation, its chromatographic separation diagram is as follows Figure 7 shown.

[0037] Depend on Figure 7 It can be seen that the chromatographic column prepared by adopting the spherical covalent organic framework material of the present invention can effectively separate thiourea from toluene, ethylbenzene and propylbenzene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com