Sealant applied to sealing of underwater optical electronic equipment and preparation method thereof

A technology for electronic equipment and sealant, applied in the direction of adhesives, natural rubber adhesives, polymer adhesive additives, etc., can solve the problems of low volatility, affecting the data transmission of optical and electronic equipment, and not considering the low radioactivity of optical equipment. , to achieve the effects of low cold flow, high rheological resistance, and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of described sealing strip, its preparation method is:

[0029] (1) Mix butyl rubber, natural rubber, low-radioactive filler, active agent, and coupling agent in an internal mixer to form a masterbatch.

[0030] (2) Heat up the kneader to 100°C-120°C, put the masterbatch into the kneader, add other fillers, and then knead under vacuum for 1h-2h, mix the sealant evenly, and discharge.

[0031] (3) After the sealant is placed for 24 hours, it is extruded into a sheet with a thickness of less than 1mm through an extruder, and the sheets are separated with silicone release paper.

[0032] The low radioactivity filler can be added in step (1) and step (2) respectively, the step (1) adds 50-70% of the total amount, and the remaining part is added in step (2).

Embodiment example 1

[0034] Sealant formulation:

[0035] The mass points of each component in the formula are: 50 parts of butyl rubber, 30 parts of natural rubber, 30 parts of low molecular polyisobutylene, 5 parts of medium molecular polyisobutylene, 10 parts of silicon dioxide, and 5 parts of polymer microspheres , 5 parts of carbon black, 5 parts of zinc oxide, 5 parts of TMTD accelerator, 2 parts of salicylanilide, 0.5 part of glycidoxypropyltrimethoxysilane.

[0036] Mix butyl rubber, natural rubber, low-radioactive filler, active agent, and coupling agent in an internal mixer to form a masterbatch. Raise the temperature of the kneader to 100°C-120°C, put the masterbatch into the kneader, add other fillers, then knead under vacuum for 1h-2h, and discharge the sealant after mixing evenly. After the sealant is placed for 24 hours, it is extruded into a sheet with a thickness of less than 1mm through an extruder, and the sheets are separated by silicone release paper.

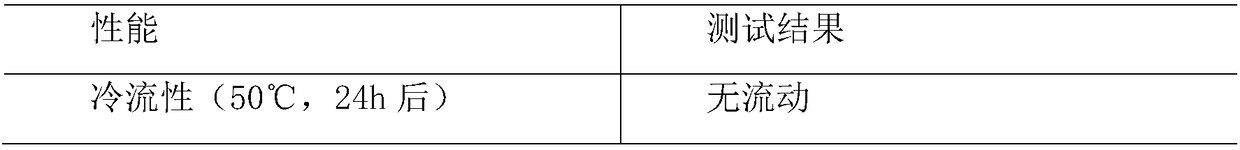

[0037] The performanc...

Embodiment example 2

[0041] Sealant formulation:

[0042] The mass points of each component in the formula are: 50 parts of butyl rubber, 10 parts of natural rubber, 10 parts of low molecular polyisobutylene, 15 parts of medium molecular polyisobutylene, 20 parts of silicon dioxide, and 5 parts of polymer microspheres , 20 parts of carbon black, 5 parts of zinc oxide, 5 parts of accelerator BZ, 2 parts of salicylanilide, and 1 part of methyltriethoxysilane.

[0043] Mix butyl rubber, natural rubber, 1 / 2 low-radioactive filler, active agent, and silane coupling agent in an internal mixer to form a masterbatch. Heat the kneader to 100°C~120°C, put the masterbatch into the kneader, add 1 / 2 of the low-radioactive filler and other fillers, then knead under vacuum for 1h~2h, after the sealant is mixed evenly, discharge . After the sealant is placed for 24 hours, it is extruded into a sheet with a thickness of less than 1mm through an extruder, and the sheets are separated by silicone release paper.

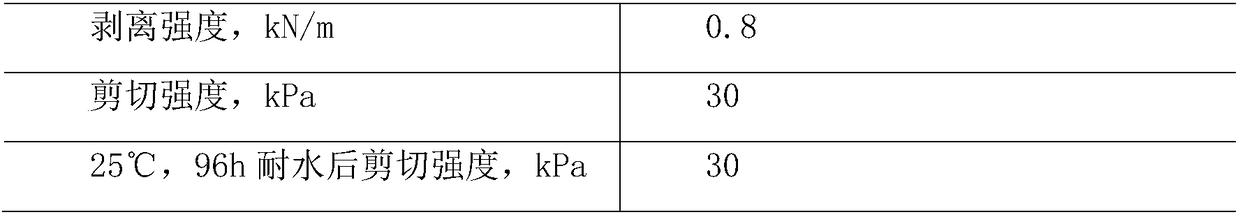

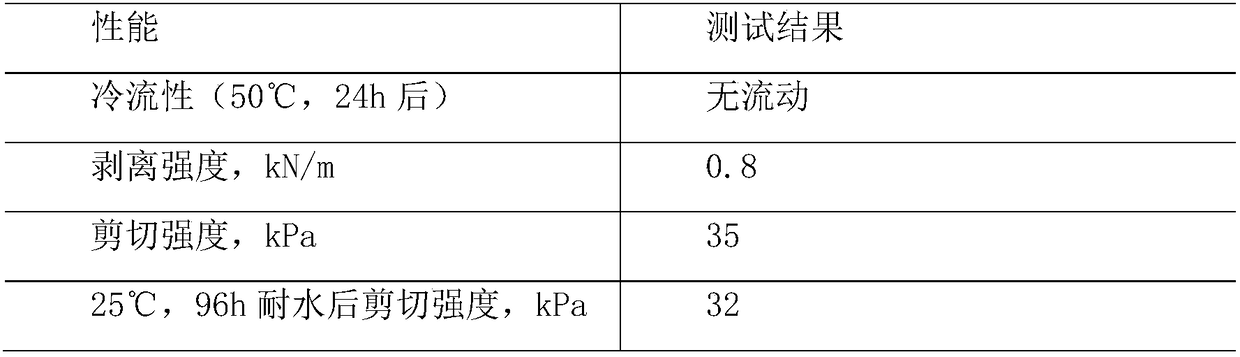

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com