Production technology of Mucuna Pruriens extract products

A production process and extract technology, which is applied in the production process of quinoa bean extract, can solve the problems of increased environmental protection pressure, short service life of filter membrane, low extraction rate, etc., to ensure product sales, increase product yield, The effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

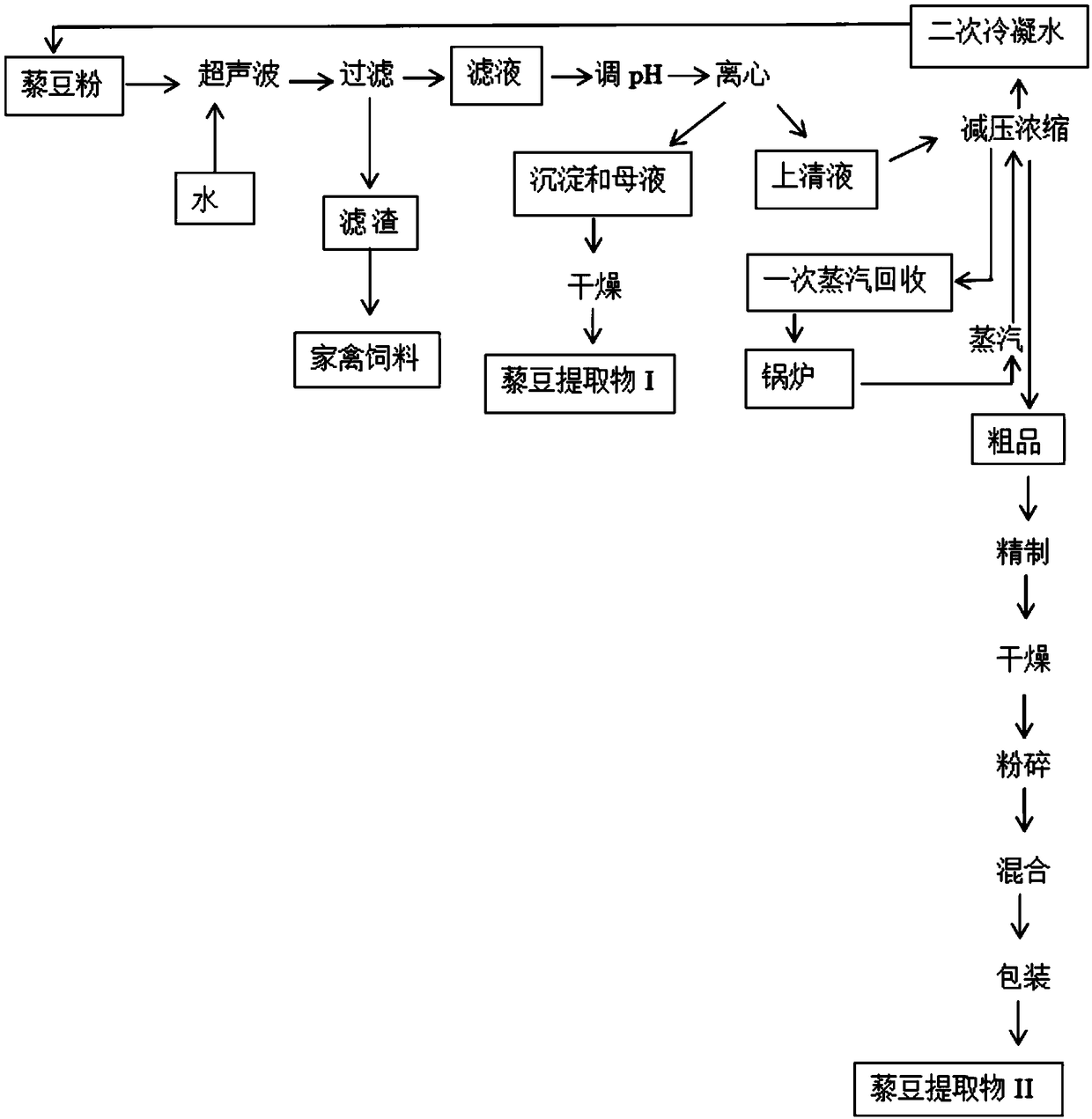

Image

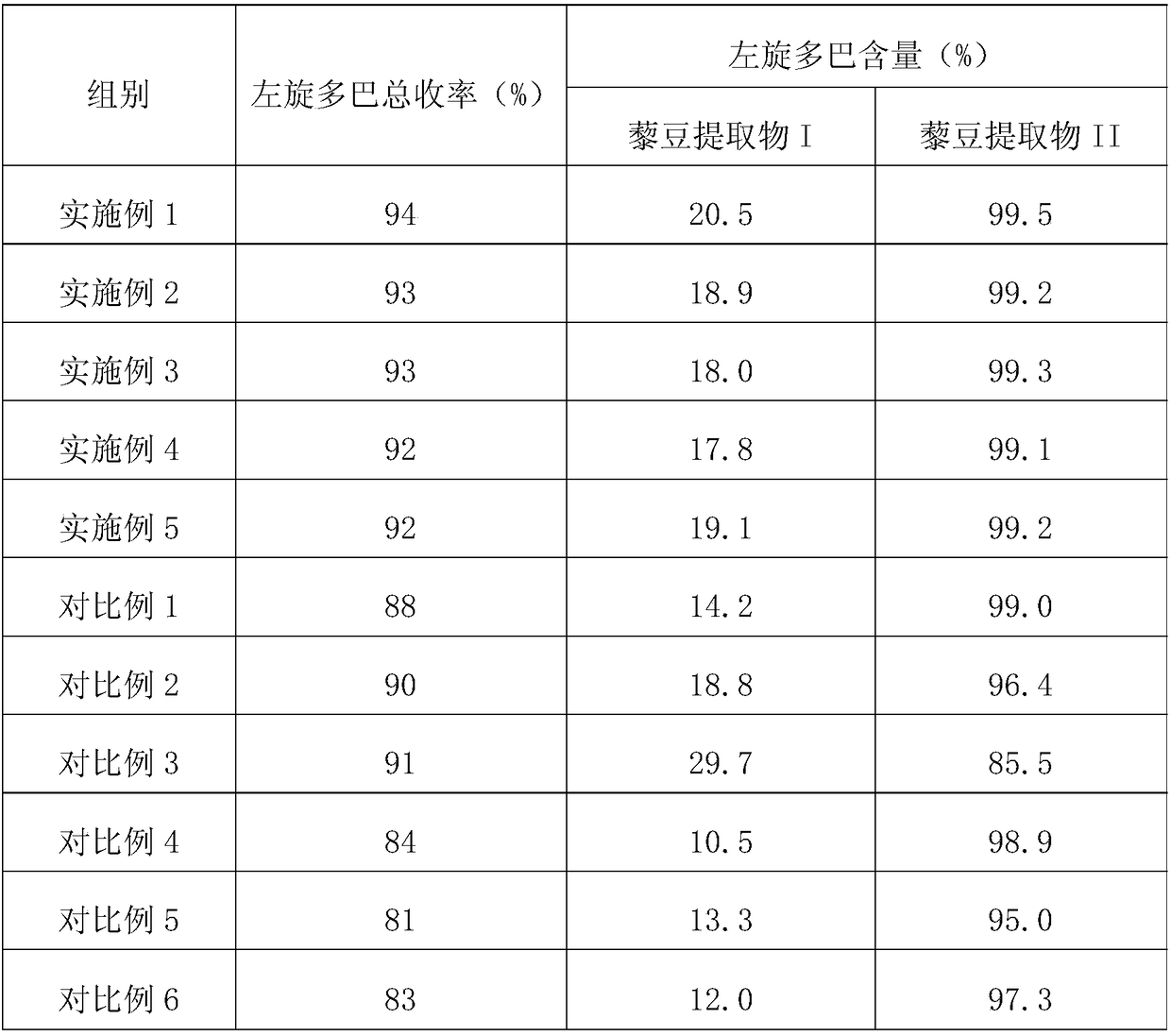

Examples

Embodiment 1

[0029] A kind of production technology of quinoa bean extract, comprises the steps:

[0030] (1) Treatment of quinoa beans: Clean the quinoa beans, grind them into powder, and pass through a 50-mesh sieve to obtain quinoa bean powder; vacuum-seal the quinoa bean powder, the thickness of the packed quinoa bean powder is 8mm, and transfer it to Zhongneng The irradiation treatment is carried out in the electron accelerator, the output energy of the electron beam is 1.5MeV, the output power is 80KW, and the transmission speed of the quinoa bean powder is 12m / min.

[0031] (2) Leaching: vitamin B3 and citric acid were added to dissolve in water, and sucrose ester was added simultaneously, and the addition amount of the sucrose ester was 0.05% of water weight; then, quinoa bean powder was added and mixed, ultrasonically extracted for 30min, ultrasonically The power is 900W, and the working temperature is 55°C; then reflux extraction for 18 hours, filter, the extraction solution is f...

Embodiment 2

[0037] A kind of production technology of quinoa bean extract, comprises the steps:

[0038](1) Treatment of quinoa beans: Clean the quinoa beans, grind them into powder, and pass through a 50-mesh sieve to obtain quinoa bean powder; vacuum-seal the quinoa bean powder, the thickness of the packed quinoa bean powder is 6mm, and transfer it to Zhongneng The irradiation treatment is carried out in the electron accelerator, the output energy of the electron beam is 1.0MeV, the output power is 60KW, and the transmission speed of the quinoa bean powder is 11m / min.

[0039] (2) Leaching: vitamin B3 and citric acid were added to dissolve in water, and sucrose ester was added simultaneously, and the addition of said sucrose ester was 0.04% of water weight; then, quinoa bean powder was added and mixed, ultrasonically extracted for 40min, ultrasonically The power is 850W, and the working temperature is 55°C; then reflux extraction for 16 hours, filter, and the extract is used for standby...

Embodiment 3

[0045] A kind of production technology of quinoa bean extract, comprises the steps:

[0046] (1) Treatment of quinoa beans: Clean the quinoa beans, grind them into powder, and pass through a 50-mesh sieve to obtain quinoa bean powder; vacuum-seal the quinoa bean powder, the thickness of the packed quinoa bean powder is 8mm, and transfer it to Zhongneng The irradiation treatment is carried out in the electron accelerator, the output energy of the electron beam is 2.0MeV, the output power is 90KW, and the transmission speed of the quinoa bean powder is 14m / min.

[0047] (2) Leaching: vitamin B3 and citric acid were added to dissolve in water, and sucrose ester was added simultaneously, and the addition amount of the sucrose ester was 0.07% of water weight; then, quinoa bean powder was added and mixed, ultrasonically extracted for 25min, ultrasonically The power is 950W, and the working temperature is 55°C; then reflux extraction for 19 hours, filter, and the extract is used for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com