Block grinding head and application of high-strength aluminum alloy in preparation of block grinding head

A high-strength, aluminum alloy technology, applied in metal processing equipment, abrasives, manufacturing tools, etc., can solve problems affecting alloy processability, material toughness, and plastic deterioration, etc., to reduce equipment costs, reduce rigidity requirements, and simplify installation and the effect of replacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

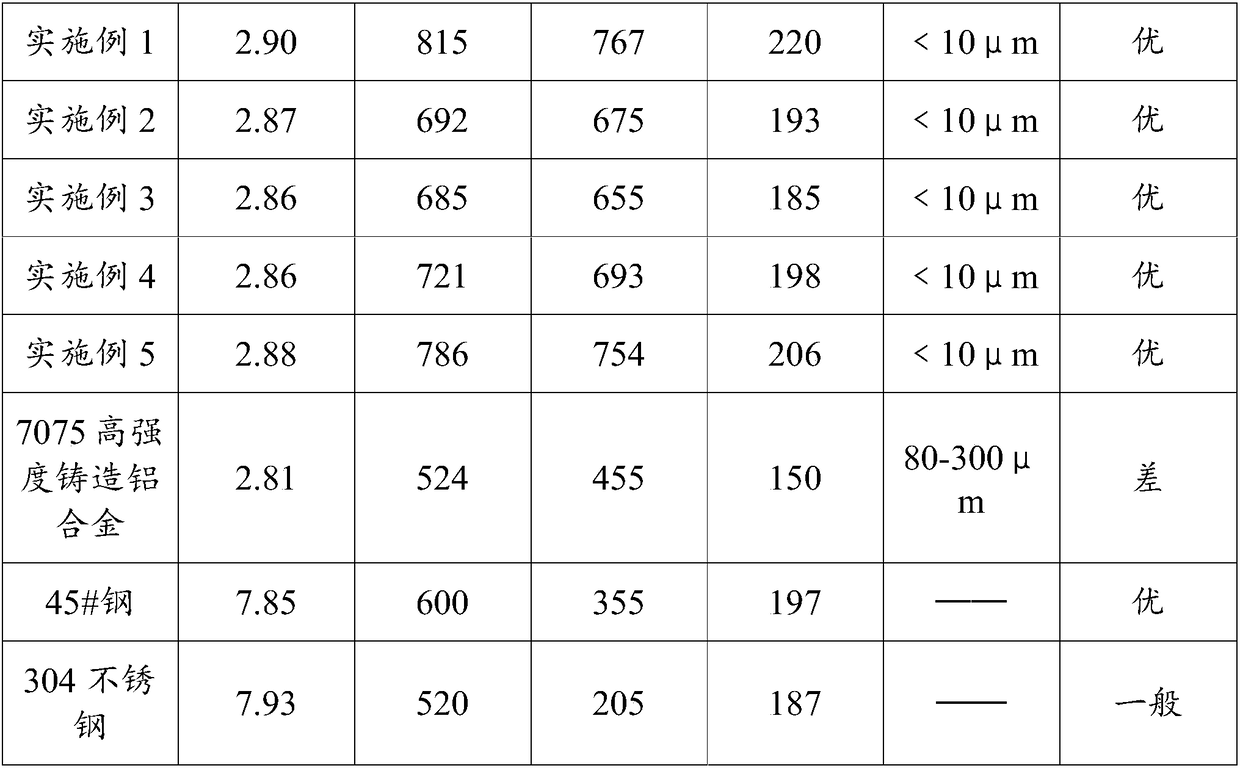

Embodiment 1

[0025] This embodiment provides a cloth grinding head, which is made of high-strength aluminum alloy as the main material. The preparation method of the cloth grinding head is as follows:

[0026] (1) 12% zinc, 2.3% copper, 2% magnesium, 0.12% zirconium, the rest are aluminum and unavoidable impurities mixed and heated to 900°C to obtain an alloy melt;

[0027] (2) The alloy melt described in step (1) is poured into the tundish, so that the melt flows out from the small hole of Φ5mm at the bottom of the tundish to become an alloy stream and enters an oxygen-free atomization chamber of an argon atmosphere, and the control The flow rate of the alloy stream is 1kg / min;

[0028] (3) In an oxygen-free atomization chamber with an argon atmosphere, spray the alloy stream described in step (2) with 0.2MPa high-pressure argon to obtain liquid droplets;

[0029] (4) The droplet described in step (3) is mixed with 10 5 The cooling rate of K / sec is rapidly cooled to deposit on the colle...

Embodiment 2

[0032] This embodiment provides a cloth grinding head, which is made of high-strength aluminum alloy as the main material. The preparation method of the cloth grinding head is as follows:

[0033] (1) 12% zinc, 2.5% copper, 2.2% magnesium, 0.14% zirconium, the rest are aluminum and unavoidable impurities mixed and heated to 750°C to obtain an alloy melt;

[0034] (2) The alloy melt described in step (1) is poured into the tundish, so that the melt flows out from the small hole of Φ5mm at the bottom of the tundish to become an alloy stream and enters an oxygen-free atomization chamber of an argon atmosphere, and the control The flow rate of the alloy stream is 4kg / min;

[0035] (3) In an oxygen-free atomization chamber with an argon atmosphere, spray the alloy stream described in step (2) with 2MPa high-pressure argon to obtain liquid droplets;

[0036] (4) The droplet described in step (3) is mixed with 10 3 The cooling rate of K / sec is rapidly cooled to deposit on the colle...

Embodiment 3

[0039] This embodiment provides a cloth grinding head, which is made of high-strength aluminum alloy as the main material. The preparation method of the cloth grinding head is as follows:

[0040] (1) 8% zinc, 2% copper, 1.8% magnesium, 0.1% zirconium, the rest are aluminum and unavoidable impurities mixed and heated to 1000°C to obtain an alloy melt;

[0041] (2) The alloy melt described in step (1) is poured into the tundish, so that the melt flows out from the small hole of Φ5mm at the bottom of the tundish to become an alloy stream and enters an oxygen-free atomization chamber of an argon atmosphere, and the control The flow rate of the alloy stream is 3kg / min;

[0042] (3) In an oxygen-free atomization chamber with an argon atmosphere, spray the alloy stream described in step (2) with 1MPa high-pressure argon to obtain liquid droplets;

[0043] (4) The droplet described in step (3) is mixed with 10 3 The cooling rate of K / sec is rapidly cooled to deposit on the collecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com