Super-strong chemical reaction type high-molecular self-adhesive rubber water-stop belt and manufacturing method thereof

A chemically reactive, self-adhesive rubber technology, used in polymer adhesive additives, non-polymer adhesive additives, adhesives, etc. Water-stopping effect, improving cohesion, and enhancing the effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

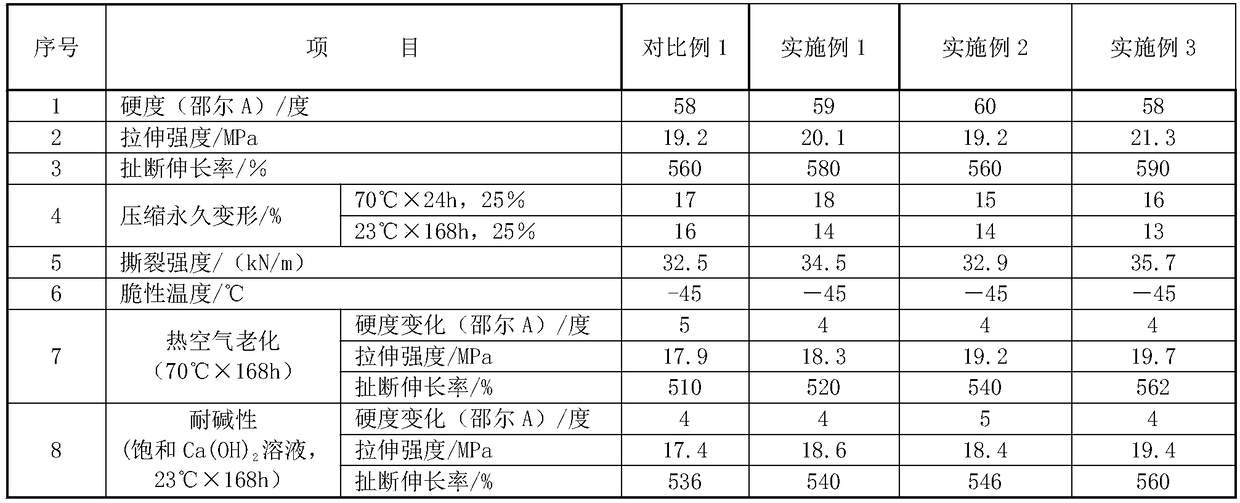

Examples

preparation example Construction

[0059] The present invention provides a preparation method of the super-strong chemical reaction type polymer self-adhesive rubber waterstop provided by the above scheme, including:

[0060] (1) first mixing and melting the softening oil, tackifying resin, antioxidant and filler to obtain the primary mixed melt;

[0061] Carrying out the second mixing and melting of the primary mixed molten material with maleic anhydride grafted SEBS and N-hexadecylpropylenediamine diammonium chloride to obtain a melted rubber mixture;

[0062] Mix and stir the melted mixture at 160-200°C for 1.5-4.5 hours to obtain self-adhesive;

[0063] (2) masticating the diene rubber, and then performing one-stage mixing of the masticated diene rubber with an active agent, an anti-aging agent, a reinforcing agent, an operating oil, and a functional filler to obtain a masterbatch;

[0064] After performing two-stage mixing of the masterbatch and the vulcanization system, the next step is performed to obta...

Embodiment 1

[0083] Preparation of self-adhesive:

[0084] (1) Add 5 parts of naphthenic oil KN4010, 30 parts of C5 petroleum resin, 2 parts of rutile titanium dioxide, and 0.2 parts of antioxidant 1010 into the reaction kettle, start heating, control the temperature at 170 ° C, and start the stirrer at the same time; ( 2) After all the above materials are melted, add 35 parts of SIS, 5 parts of maleic anhydride grafted SEBS and 0.1 part of N-hexadecylpropylenediamine bisammonium chloride, and keep the temperature at 170°C for mixing and melting; ( 3) After all the materials are melted, keep warm at 160°C and continue to stir for 1.5 hours to form a self-adhesive glue for super-strong chemical reaction polymer self-adhesive rubber waterstop.

[0085] Extrusion process of rubber substrate:

[0086] (1) Pretreatment of hydrotalcite: calcining the hydrotalcite raw material at a high temperature of 450° C. for 20 minutes.

[0087] (2) Add natural rubber into the internal mixer, and masticate...

Embodiment 2

[0095] Preparation of self-adhesive:

[0096] (1) Add 20 parts of naphthenic oil KN4010, 60 parts of C5 petroleum resin, 5 parts of nano-calcium powder, and 1 part of antioxidant 168 into the reaction kettle, start heating, control the temperature at 170 ° C, and start the stirrer at the same time; (2 ) After the above materials are all melted, add 60 parts of SIS, 15 parts of maleic anhydride grafted SEBS and 5 parts of N-hexadecylpropylenediamine bisammonium chloride, and keep the temperature at 190°C for mixing and melting; (3 ) After all the materials are melted, keep warm at 160-200°C and continue to stir for 4.5 hours to form a self-adhesive for super-strong chemical reaction polymer self-adhesive rubber waterstop.

[0097] Extrusion process of rubber substrate:

[0098] (1) Pretreatment of hydrotalcite: Calcining the montmorillonite for 80 minutes at a high temperature of 450°C.

[0099] (2) Add natural rubber into the internal mixer, and masticate for 5 minutes at an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com