Method for separating and purifying antioxidant substance from wisteria

A technology for separation and purification of antioxidant substances, applied in the field of separation and purification, can solve problems such as unclear targets, large sample loss, and cumbersome steps, and achieve good separation effects, no sample loss, and large preparation volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

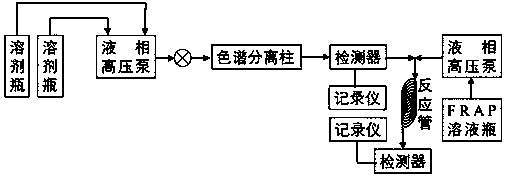

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Take 50.00 g of wisteria flowers that have been dried and crushed to 20 meshes, add 400 mL of ethanol with a volume concentration of 50% as the extraction solvent, and extract in an ultrasonic-microwave extractor for 30 minutes. The ultrasonic power is 400W and the microwave power is 400W. Ultrasonic-microwave extraction After filtration, the filter residue was repeatedly extracted 4 times, and the filtrate was combined and concentrated in vacuo at 60°C to obtain the wisteria flower extract;

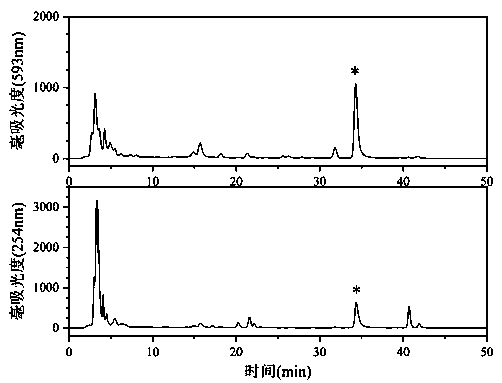

[0035]Step 2: Set the conditions of high performance liquid chromatography, the wavelength is 254nm, Megres C18 column (4.6mm×250mm, 5μm), mobile A phase: water, mobile B phase: acetonitrile; column temperature: 30°C, flow rate 0.8mL / min, injection volume 10μL, gradient elution conditions: 0-5min, 20% B; 5-25min, 20%-30% B; 25-35min, 30%-40% B; 35-40min, 40% B; 40-45min, 40%-20% B; 45-50min, 20% B, under this condition, carry out chromatographic analysis on the extract of...

Embodiment 2

[0042] Step 1: Take 10.00 g of wisteria flowers that have been dried and crushed to 20 meshes, add 60 mL of ethanol with a volume concentration of 70% as the extraction solvent, and extract in an ultrasonic-microwave extractor for 10 minutes. The ultrasonic power is 180W, and the microwave power is 30W. After the completion of filtration, the filter residue was repeatedly extracted 3 times, and the filtrate was combined and concentrated in vacuum at 60°C to obtain the wisteria flower extract;

[0043] Step 2: the implementation mode is the same as step 2 of Example 1;

[0044] Step 3: the implementation mode is the same as Step 3 of Example 1;

[0045] Step 4: Use a solvent system of n-hexane-ethyl acetate-ethanol-water with a volume ratio of 3:5:3:5, the upper phase is the stationary phase, the lower phase is the mobile phase, and the flow rate of the mobile phase is 2 mL / min. The column rotation speed was 900 rpm, and the Wisteria flower extract was separated by high-speed ...

Embodiment 3

[0047] Step 1: Take 100.00 g of wisteria flowers that have been dried and crushed to 20 meshes, add 600 mL of ethanol with a volume concentration of 90% as the extraction solvent, and extract in an ultrasonic-microwave extractor for 30 minutes. The ultrasonic power is 900W, and the microwave power is 900W. Ultrasonic-microwave extraction After filtration, the filter residue was repeatedly extracted 3 times, and the filtrates were combined and concentrated in vacuo at 60°C to obtain the wisteria flower extract.

[0048] Step 2: the implementation mode is the same as step 2 of Example 1;

[0049] Step 3: the implementation mode is the same as Step 3 of Example 1;

[0050] Step 4: using a solvent system of n-hexane-ethyl acetate-ethanol-water with a volume ratio of 4:5:3:5, the upper phase is the stationary phase, the lower phase is the mobile phase, and the flow rate of the mobile phase is 1.5 mL / min. The rotation speed of the separation column was 900 rpm, and the Wisteria flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com