Anode sheet, a secondary battery and a manufacturing method of the anode sheet

A manufacturing method and technology of anode sheets, which are applied in the direction of secondary batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of reducing the lithium utilization rate of LPD silicon anode, uneven lithium intercalation amount of silicon anode, and uneven lithium intercalation amount, etc., to achieve Uniform lithium intercalation, reduced contact area, and high lithium utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

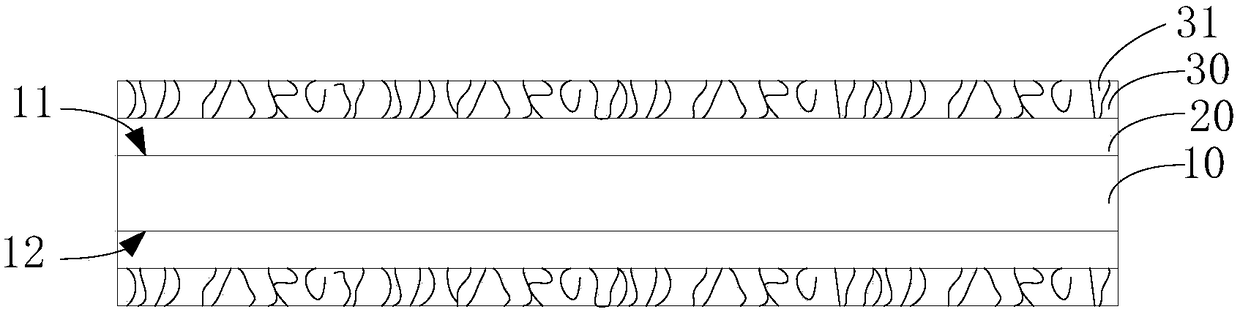

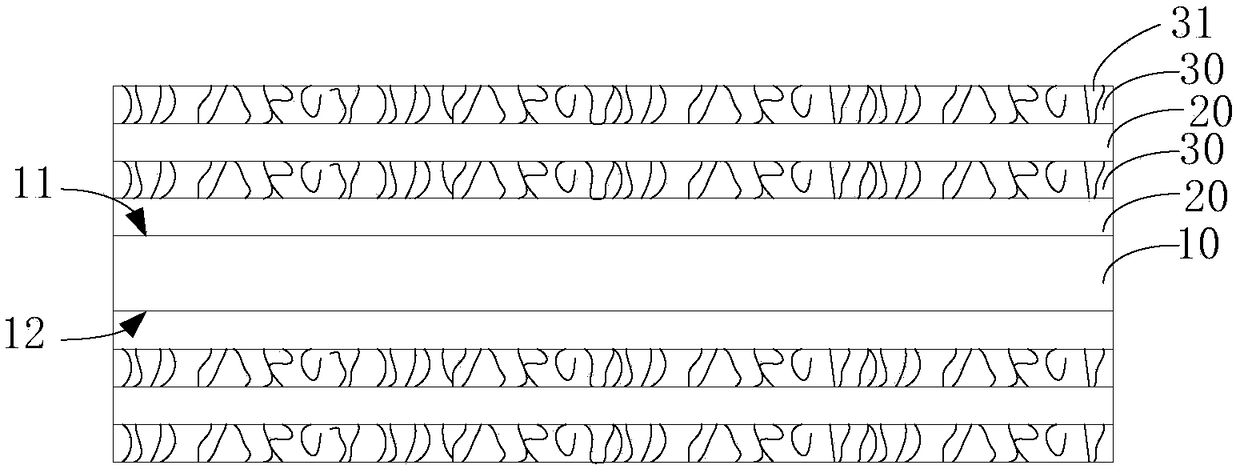

Image

Examples

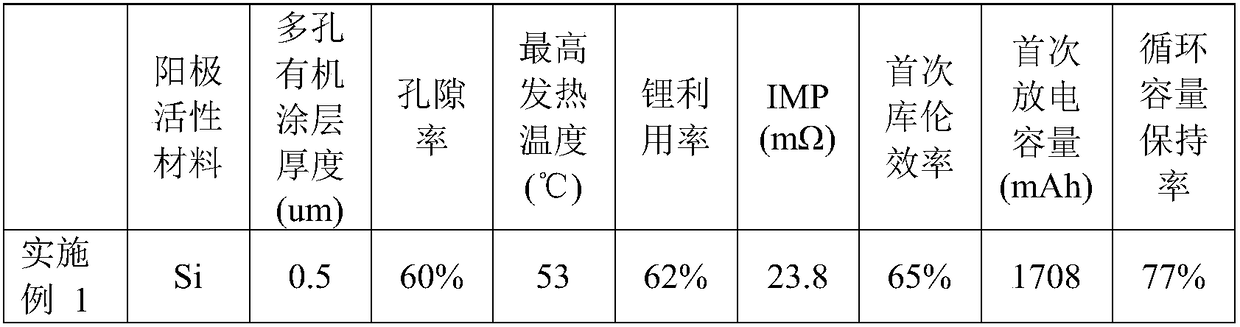

Embodiment 1

[0062] Anode Sheet Manufacturing:

[0063] Mix the mixture of anode active material Si, anode binder styrene-butadiene rubber, anode conductive agent conductive carbon black SuperP, and deionized water in a mass ratio of 90:5:5 to make an anode slurry;

[0064] According to 102mg / 1540mm 2 The coating weight of the anode slurry is evenly coated on the front and back surfaces of the anode current collector copper foil, and the initial anode sheet is manufactured after drying in a 100°C oven;

[0065] Mix PANI, Pyy and PEDOT / PSS according to the mass ratio a:b:c=1:0:0, and then stir it with deionized water according to the mass ratio of 1:9 to form a conductive polymer slurry, and use dimple coating The conductive polymer slurry is coated on the two opposite surfaces of the initial anode sheet by means of cloth, and a porous conductive polymer layer is formed after drying, wherein the thickness of the conductive polymer layer is 0.5um, and the porosity is 60%;

[0066] The meta...

Embodiment 2

[0068] Anode Sheet Manufacturing:

[0069] The manufacturing method of the anode sheet in this example is the same as that in Example 1, the difference is that the anode active material is SiOx, where x<2, the mass ratio of PANI, Pyy and PEDOT / PSS is a:b:c=0:1:0, conductive polymerization The thickness of the material layer is 2um, and the porosity is 47%.

Embodiment 3

[0071] Anode Sheet Manufacturing:

[0072] The manufacturing method of the anode sheet in this example is the same as in Example 1, the difference is that the anode active material is a mixture of Si-C, the mass ratio of PANI, Pyy and PEDOT / PSS is a:b:c=0.5:0.25:0.25, and the conductive polymer The layer thickness is 5um and the porosity is 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com