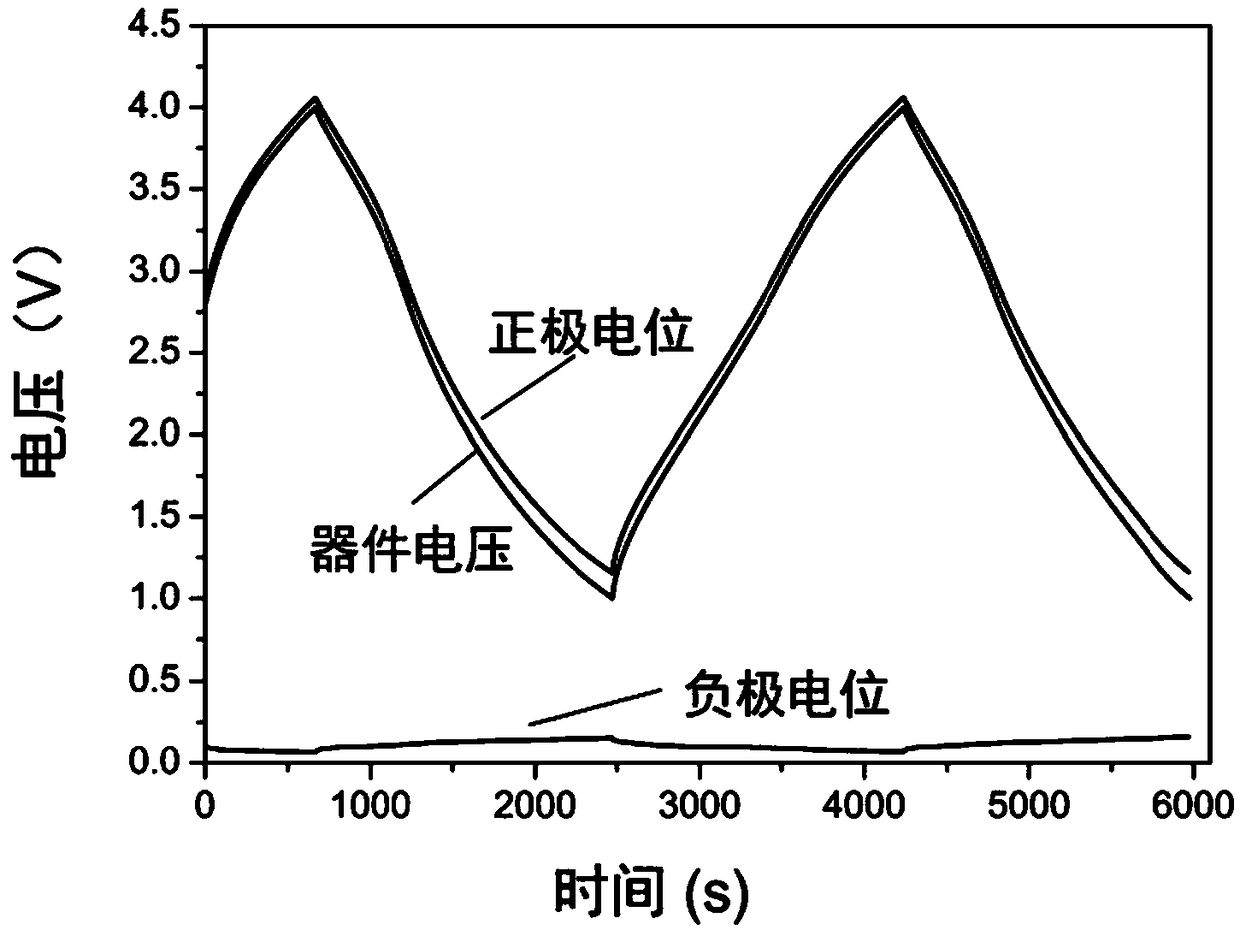

A Li-ion Capacitor with High Energy Density

A high-energy density, lithium-ion technology, applied in capacitors, electrolytic capacitors, hybrid capacitors, etc., can solve the problems of low specific capacity of negative electrode materials, narrow voltage window of lithium-ion capacitors, and high voltage of lithium titanate charging and discharging platforms, so as to improve Effects of energy density and cycle life, reduction of negative electrode potential, and reduction of transmission resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 positive electrode sheet

[0028] Take 5 parts by mass of sodium carboxymethylcellulose and dissolve it in 2000 parts by mass of deionized water, then add 30 parts by mass of styrene-butadiene rubber and mix evenly, then add 50 parts by mass of conductive carbon black and 500 parts by mass of activated carbon , mixed evenly to make a slurry. The slurry is coated on an aluminum foil with a porosity of 5%, and a positive electrode sheet is made through processes such as drying, rolling, and slitting.

Embodiment 2

[0029] Example 2 Preparation of Positive Electrode Sheet

[0030] Take 30 parts by mass of LA135 binder and 5 parts by mass of polytetrafluoroethylene binder and dissolve them in 2000 parts by mass of deionized water, add 40 parts by mass of conductive carbon black, 10 parts by mass of conductive graphite and 400 parts by mass of The activated carbon of 100 parts, the activated carbon fiber of 100 parts by mass, mix uniformly, make slurry. The slurry is coated on an aluminum foil with a porosity of 20%, and a positive electrode sheet is made through processes such as drying, rolling, and slitting.

Embodiment 3

[0031] Embodiment 3 Preparation of positive electrode sheet

[0032] Take 20 mass parts of LA135 binder and 15 mass parts of polytetrafluoroethylene binder and dissolve it in 2000 mass parts of deionized water, add 40 mass parts of conductive carbon black, 10 mass parts of conductive graphite and 400 mass parts The activated carbon of 100 parts, the graphene of 100 parts by mass, mix uniformly, make slurry. The slurry is coated on an aluminum foil with a porosity of 30%, and a positive electrode sheet is made through processes such as drying, rolling, and slitting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com