Negative electrode unit of a lithium ion capacitor and preparation method thereof, lithium ion capacitor

A capacitor and lithium ion technology, which is applied in the field of lithium ion capacitors, can solve the problems that the gas of the negative electrode sheet cannot be discharged in time, and the electrolyte cannot be fully contacted with the lithium sheet, so as to achieve good product consistency, reduce the probability of self-discharge, and improve utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]The negative electrode unit of the lithium ion capacitor of the present embodiment includes a negative electrode sheet, and the negative electrode sheet includes a negative electrode current collector copper foil and a negative electrode active material layer coated on both surfaces of the negative electrode current collector. The agent Super P and the binder polyvinylidene fluoride (PVDF) are evenly mixed according to the mass ratio of 90:3:7. The thickness of the negative electrode sheet is 200 μm, and the surface of the negative electrode active material layer on both sides of the negative electrode sheet is covered with lithium mesh. The porosity of the net is 25%, the mass ratio of the lithium net to the negative active material is 0.05:1, and the overall laying area of the lithium net is greater than the area of the negative active material layer on the surface of the negative plate to completely cover the negative active material layer.

[0037] The preparation...

Embodiment 2

[0045] The negative electrode unit of the lithium ion capacitor of the present embodiment includes a negative electrode sheet, and the negative electrode sheet includes a negative electrode current collector copper foil and a negative electrode active material layer coated on both surfaces of the negative electrode current collector. The agent Super P and the binder polytetrafluoroethylene (PTFE) are evenly mixed according to the mass ratio of 86:5:9. The thickness of the negative electrode sheet is 200 μm, and the negative electrode active material layer on both sides of the negative electrode sheet is covered with lithium mesh. The porosity of the net is 50%, the mass ratio of the lithium net to the negative active material is 0.08:1, and the overall laying area of the lithium net is greater than the area of the negative active material layer on the surface of the negative plate to completely cover the negative active material layer.

[0046] The preparation method of the...

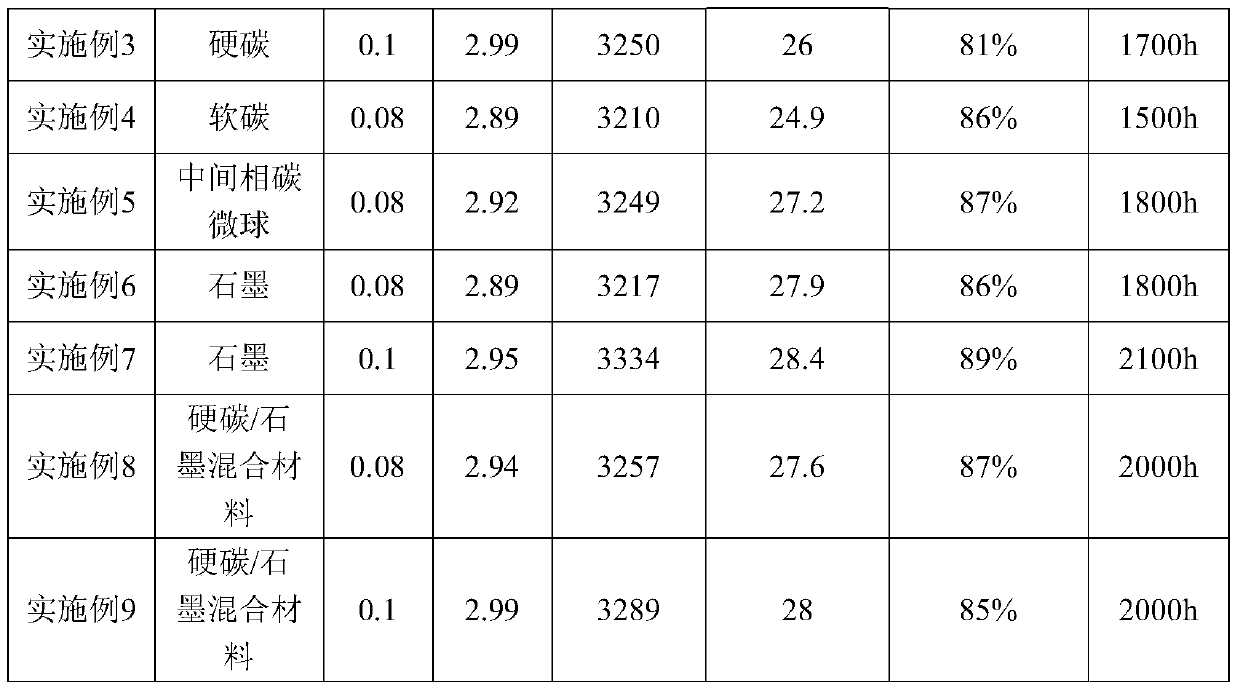

Embodiment 3

[0054] The negative electrode unit of the lithium ion capacitor of the present embodiment includes a negative electrode sheet, and the negative electrode sheet includes a negative electrode current collector copper foil and a negative electrode active material layer coated on both surfaces of the negative electrode current collector. Super P and mixed binder are evenly mixed according to the mass ratio of 90:3:7, and the mixed binder is made of styrene-butadiene rubber (SBR) and carboxymethyl cellulose (CMC) according to the mass ratio of 5:3 , the thickness of the negative electrode sheet is 200 μm, and the surface of the negative electrode active material layer on both sides of the negative electrode sheet is covered with a lithium mesh, the porosity of the lithium mesh is 70%, and the mass ratio of the lithium mesh to the negative electrode active material is 0.1:1. The laying area is larger than the area of the negative electrode active material layer on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com