Long-fiber reinforced thermoplastic resin composite material forming device and technology

A technology of resin composite materials and enhanced thermoplasticity, applied in the field of long fiber reinforced thermoplastic resin composite materials, can solve the problems of low running speed, stress concentration, fiber breakage, etc., to improve reliability and stability, reduce stress concentration, and reduce stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

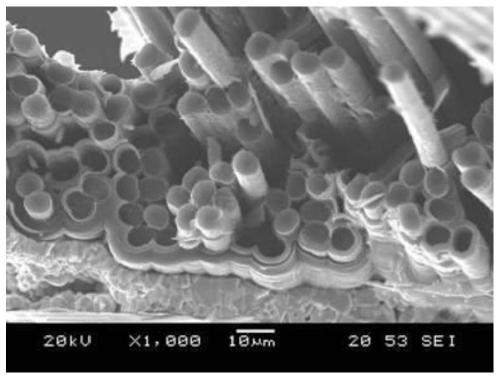

[0061] This embodiment provides a molding device for long-fiber reinforced thermoplastic resin composite materials, including: sequentially distributed fiber concave tube channels 2, air-flow fiber opening device 3, mechanical spreading roller 4, fiber infiltration molding device, cooling and shaping device 11 and cutting Cutting unit 12; wherein the fiber infiltration molding device includes a fiber inlet module 5, a molten resin impregnation mold 7 and a fiber outlet module 10, and the interior of the molten resin impregnation mold 7 includes a counter-pressure roller 6 and a tension roller 8 arranged in sequence, and the tension roller 8 The quantity is 3.

[0062] During implementation, the fiber bundle 1 enters the fiber concave tube channel 2 and then passes through the airflow opening device 3, then passes through the mechanical spreading roller 4, then passes through the fiber infiltration forming device, and after passing through the cooling and shaping device 11, ente...

Embodiment 2

[0070]This embodiment provides a molding device for long-fiber reinforced thermoplastic resin composite materials. The overall structure of the molding device is the same as that of the device in Embodiment 1, the difference is that:

[0071] There are concave channels arranged in parallel on the fiber concave tube channel 2, the number of concave channels is 20, and one concave channel passes through two 24K carbon fiber bundles; the gas velocity of the airflow fiber opening device 3 is 15m / s; the mechanical expansion The number of rollers 4 is 4, and the heating temperature is 280°C; the distance between the fiber feeding module 5 and the mechanical unfolding roller 4 is 0.15 meters; the distance between the two rollers of the pressure roller 6 is 0.8mm; the height of the tension roller 8 is 2 / 3 of the internal height of the resin impregnation mold 7; the screw extruder 9 is a twin-screw extruder, and the resin used is polyamide 66; the fiber outlet module 10 is distributed w...

Embodiment 3

[0078] This embodiment provides a molding device for long-fiber reinforced thermoplastic resin composite materials. The overall structure of the molding device is the same as that of the device in Embodiment 1, the difference is that:

[0079] Concave channels arranged in parallel are distributed on the fiber concave tube channel 2, the number of which is 20, and one concave channel passes through three 2400tex glass fiber bundles; the gas velocity of the airflow fiber opening device 3 is 15m / s; The number of mechanical spreading rollers 4 is 5, and the heating temperature is 220° C.; the distance between the fiber feeding module 5 and the mechanical spreading rollers 4 is 0.12 meters; the distance between the two rollers of the pressure roller 6 is 1 mm; the height of the tension roller 8 is 3 / 5 of the internal height of the molten resin impregnation mold 7; the screw extruder 9 is a single screw extruder, and the resin used is high-density polyethylene; the fiber outlet modul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com