Non-woven fabric capable of enabling liquid to quickly underflow and inhibiting backflow and preparation method of non-woven fabric

A non-woven fabric and liquid technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve problems such as the influence of human body comfort, the surface cannot be kept dry, and the liquid seepage speed is slow, so as to achieve flexible adjustment and prevent back seepage , the effect of inhibiting rewet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

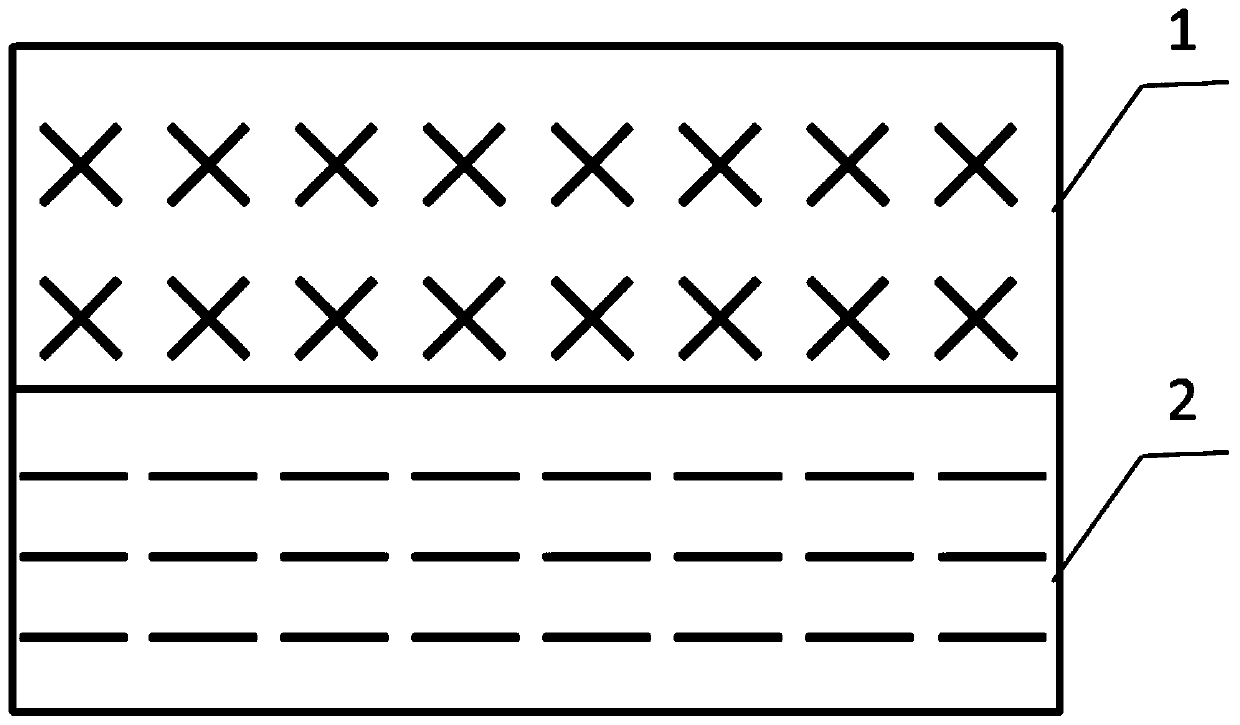

[0021] Such as figure 1 As shown, it is the non-woven fabric of this embodiment that can make the liquid permeate quickly and inhibit the rewetting. It is composed of the upper layer non-woven fabric 1 and the lower layer non-woven fabric 2. The non-woven fabric is prepared by carding and cross-lapping. The upper non-woven fabric 1 has a high degree of randomness, and the liquid can infiltrate in all directions along the surface of the non-woven fabric, and the infiltration speed is fast. The lower non-woven fabric 2 is prepared by ES polyphilic fibers through a non-woven direct laying process, and then stretched by a stretching machine to obtain the lower non-woven fabric 2, wherein the fibers are oriented and arranged along the machine direction to form a fixed Guide the water, the liquid reaches the lower layer and flows along the direction of the machine on the horizontal plane, which helps to guide and disperse better.

[0022] The preparation method of the above-mention...

Embodiment 2

[0028] A method for preparing a non-woven fabric that can quickly infiltrate liquid and inhibit rewetting:

[0029] Step 1: Prepare ES monophilic fibers, weigh ES monophilic fibers of the required quality, and make them with an area density of 40g / m through non-woven carding and cross-lapping processes 2 fiber web A;

[0030] Step 2: Prepare ES multiphile fibers, weigh the ES multiphile fibers of the required quality, and then stretch the fiber web B under the condition of a pressure of 5N through the non-woven direct laying process to improve the fiber in the machine direction. Degree of orientation; after stretching, the fiber web is elongated to 1.3 times the original length; the surface density is 30g / m 2 fiber web B;

[0031] Step 3: Composite fiber web A and fiber web B by parallel laying, and place fiber web A above fiber web B to obtain a composite fiber web;

[0032] Step 4: Carry out hot rolling bonding and strengthening of the composite fiber web, feed the compos...

Embodiment 3

[0034] A preparation method of a non-woven fabric that can make liquid permeate quickly and inhibit rewetting:

[0035] Step 1: Prepare ES monophilic fibers, weigh ES monophilic fibers of the required quality, and make them with an area density of 40g / m through non-woven carding and cross-lapping processes 2 fiber web A;

[0036] The second step: prepare the ES multiphile fiber, weigh the ES multiphile fiber of the required quality, through the non-woven direct laying process, and then stretch the fiber web B under the condition of a pressure of 5N, and improve the machine The degree of fiber orientation in the direction; after stretching, the fiber web is elongated to 1.3 times the original length; the surface density is 30g / m 2 fiber web B;

[0037] Step 3: Acupuncture and reinforce the fiber web A to endow the fiber web A with a certain strength, and adopt one pre-acupuncture, one front acupuncture and one reverse acupuncture to obtain the upper non-woven fabric 1;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com