Lithium ion capacitor and preparation method thereof

A technology of capacitors and lithium ions, which is applied in the field of capacitors and can solve problems such as harsh lithium-intercalation environment requirements, inability to promote industrial applications, uneven lithium-intercalation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The present invention provides a kind of preparation method of lithium ion capacitor described in above-mentioned technical scheme, comprises the following steps:

[0062] Mix the negative electrode active material, conductive carbon black and polyvinylidene fluoride, add N-methylpyrrolidone to adjust the viscosity, and then coat it on the copper foil current collector to obtain the negative electrode sheet; pre-prepare the negative electrode sheet in the aromatic lithium compound Lithiation to obtain a pre-lithiated negative electrode sheet;

[0063] Mix the positive electrode active material, conductive carbon black and sodium alginate, add water to adjust the viscosity, and then coat it on the aluminum foil current collector to obtain the positive electrode sheet;

[0064] The pre-lithiated negative electrode sheet and the positive electrode sheet are assembled to obtain a lithium ion capacitor.

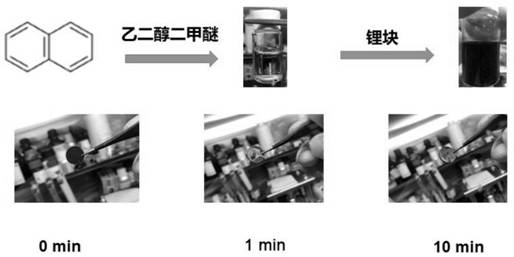

[0065] In the present invention, the aromatic lithium compound is pre...

Embodiment 1

[0078] The preparation steps of the rod-shaped magnesium oxide template are as follows:

[0079] Step (1) Na 2 CO 3 and MgCl 2 ·6H 2 O is configured as a 1mol / L solution;

[0080] Step (2) gets the Na of 100ml respectively 2 CO 3 solution and MgCl 2 solution, the Na 2 CO 3 The solution was slowly added to the MgCl 2 solution, and stirred evenly, and then it was left to stand for 6 hours to filter and collect the filter cake after the reaction was completed, washed with deionized water for 3-5 times, and dried in a blast drying oven;

[0081] Step (3) The collected product was calcined in air at a rate of 5° C. / min to 550° C. for 2 hours to obtain a rod-shaped magnesium oxide template.

Embodiment 2

[0083] The preparation steps of the hierarchical porous structure magnesium oxide template are as follows:

[0084] Take 2 g of the rod-shaped magnesium oxide template prepared in Preliminary Example 1, add it to 400 ml of deionized water and stir it evenly, leave it to stand for a period of time at room temperature, then filter, and dry the filter cake in a blast drying oven Dry;

[0085] The collected product was calcined in the air at a rate of 5° C. / min to 550° C. for 2 hours to obtain a magnesium oxide template with a hierarchical porous structure.

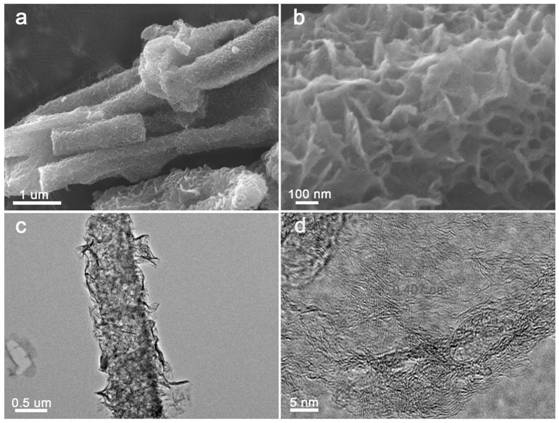

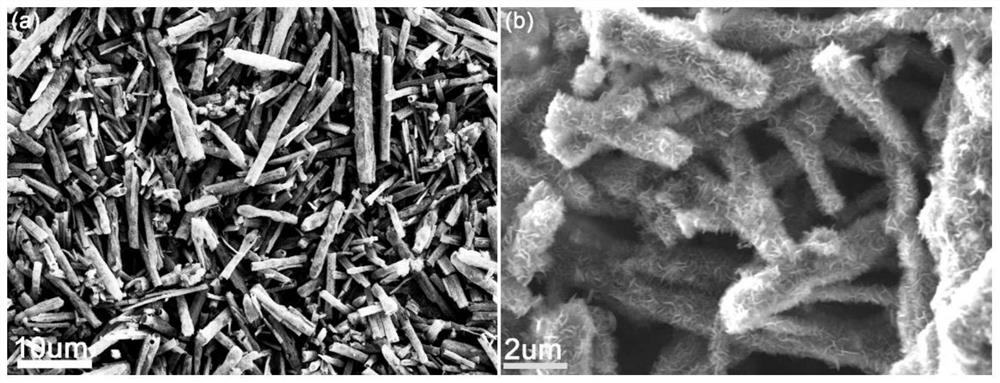

[0086] figure 1 For the SEM figure of the template prepared in preliminary example 1 and preliminary example 2, wherein, a is the SEM figure of the rod-shaped porous magnesium oxide template prepared in preliminary example 1; b is the SEM of the hierarchical porous magnesium oxide template prepared in preliminary example 2 figure; from figure 1 It can be seen from the figure that the magnesium oxide reacted in water presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com