Straw-wood chip honeycomb fuel and preparation method thereof

A technology of sawdust and straw, applied in the field of straw sawdust honeycomb fuel and its preparation, can solve the problems of many ingredients, high failure rate, low output and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

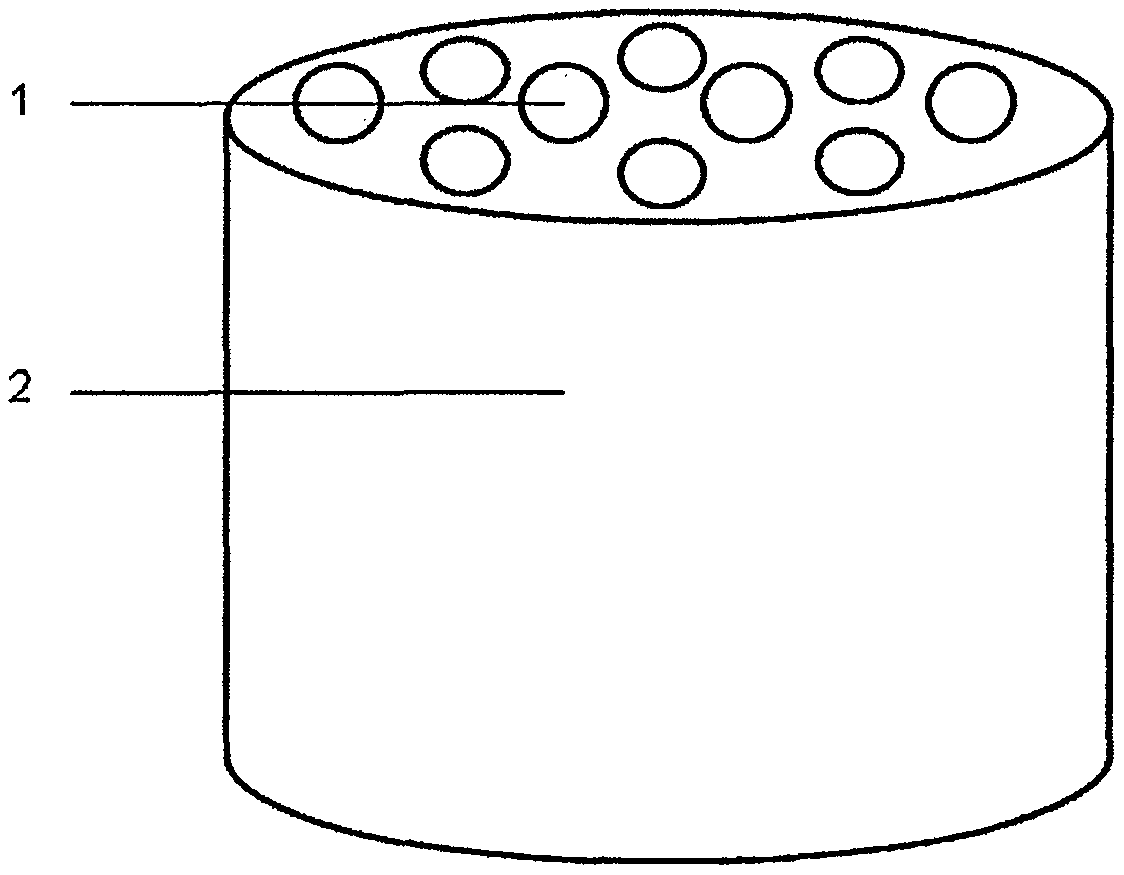

[0011] A kind of straw sawdust honeycomb fuel and its preparation method are implemented according to the following steps:

[0012] (1) Crush the straw sawdust into fragments with a particle size ≤ 5mm; (2) Mix CaO and straw sawdust at a weight ratio of 3:4-5, stir evenly, add an appropriate amount of water and stir to form a cohesive shape; (3) mix The bondable mixture is fed into a briquette machine to be pressed into straw and sawdust honeycomb balls; (4) the straw and sawdust honeycomb balls are dried; (5) placed in a closed room and baked at a temperature below 290 degrees to make carbonization. (6) Before leaving the factory, spray a solution of potassium permanganate with a concentration of 0.5% to 1% on the dried straw sawdust honeycomb balls and the inside of the honeycomb holes, and dry them in the air.

Embodiment 2

[0014] A kind of straw sawdust honeycomb fuel and its preparation method are implemented according to the following steps:

[0015] (1) Crush the straw sawdust into fragments with a particle size ≤ 5mm; (2) Mix CaO and straw sawdust in a weight ratio of 3:4, stir evenly, add water and stir to form a sticky shape; (3) mix the sticky (4) Dry the straw and sawdust honeycomb balls; (5) Put them in a closed room and bake them at a temperature below 300 degrees to make carbonization; (6) Before leaving the factory, use a concentration Spray 0.5% to 1% potassium permanganate solution on the dried straw sawdust honeycomb balls and inside the honeycomb holes, and let it dry.

[0016] What is described above is only an implementation example of the present invention, and common knowledge such as specific structures and characteristics known in the scheme are not described here too much. For those skilled in the art, under the premise of not departing from the structure of the present i...

specific Embodiment 2

[0018] It is basically the same as the specific implementation example 1, but there are two differences. The first is that the shape of the culture medium becomes a cuboid. 2 is that the transplanting groove becomes a cylinder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com