Device for preheating and softening automobile leather hose

A leather tube and tube groove technology, which is applied in the field of auto parts processing equipment, can solve the problems of excessive hardness and insufficient softness, inconvenient processing and assembly, etc., and achieves the effect of avoiding cross-flow of water stains and saving water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

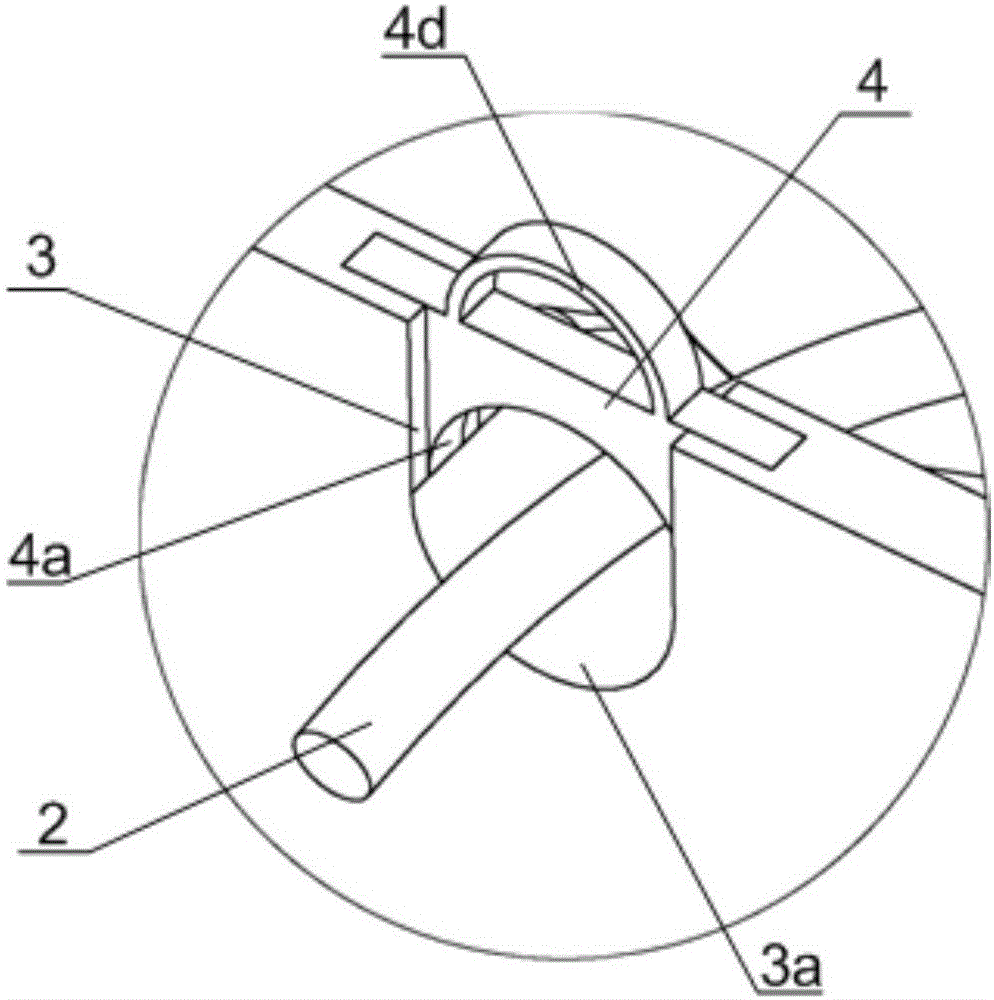

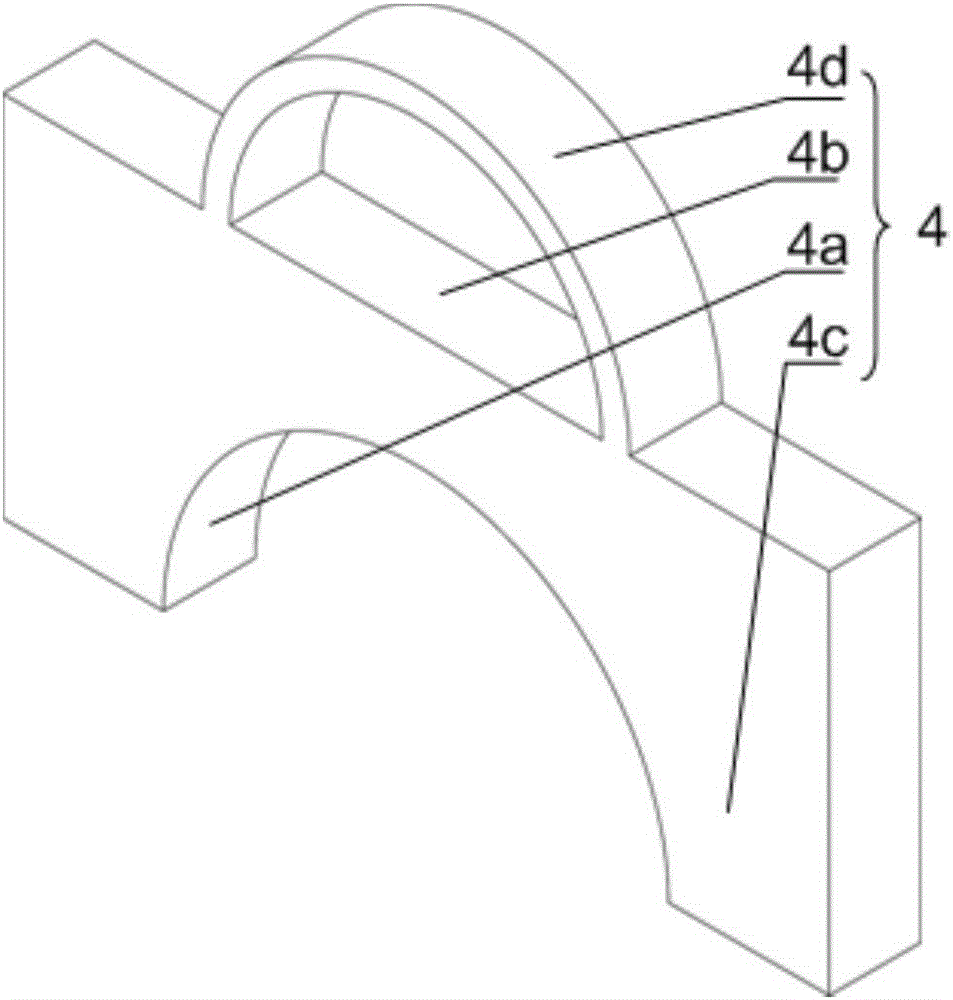

[0031] see Figure 1 to Figure 6 As shown, the present invention provides a device for preheating and softening leather tubes for vehicles, including a water storage tank 1 and a stop assembly arranged in the water storage tank 1 for limiting the leather tube 2 in water , wherein, the water storage tank 1 includes a rectangular bottom plate 1a, two lateral side plates 1b vertically fixed on the shorter side of the bottom plate 1a, and two lateral side plates 1b vertically fixed on the longer side of the bottom plate 1a. Two longitudinal side plates 1c; the tops of the two lateral side plates 1b are provided with a pipe running groove 3, and a side plate limit block 4 is inserted on the pipe running groove 3, and the bottom of the pipe running groove 3 and The lower end of the side plate limiting block 4 is respectively provided with a first se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com