Adhesive for clay print drawing and clay print drawing method

An adhesive and clay print technology, which is applied in special decorative structures, specialized techniques of artistic painting, decorative arts, etc., can solve the problems of thick and heavy mud layer, unsatisfactory effect, and easy falling off of mud, so as to avoid visual pollution. , the effect of increasing artistry and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] As a preferred embodiment, the binder is prepared from raw materials including the following components in parts by weight: 20 parts of polymer emulsion, 15 parts of active chemical substances, 10 parts of fine aggregate, and 5 parts of additives, 93 parts of muddy cement.

[0031] As a preferred embodiment, the binder is prepared from raw materials including the following components in parts by weight: 15 parts of polymer emulsion, 13 parts of active chemical substances, 8 parts of fine aggregate, and 5 parts of additives, 95 parts of muddy cement.

[0032] As a preferred embodiment, the polymer emulsion is one or more mixtures of VAE emulsion, polyacrylate copolymer emulsion or neoprene emulsion.

[0033] A clay print drawing method, comprising the following steps:

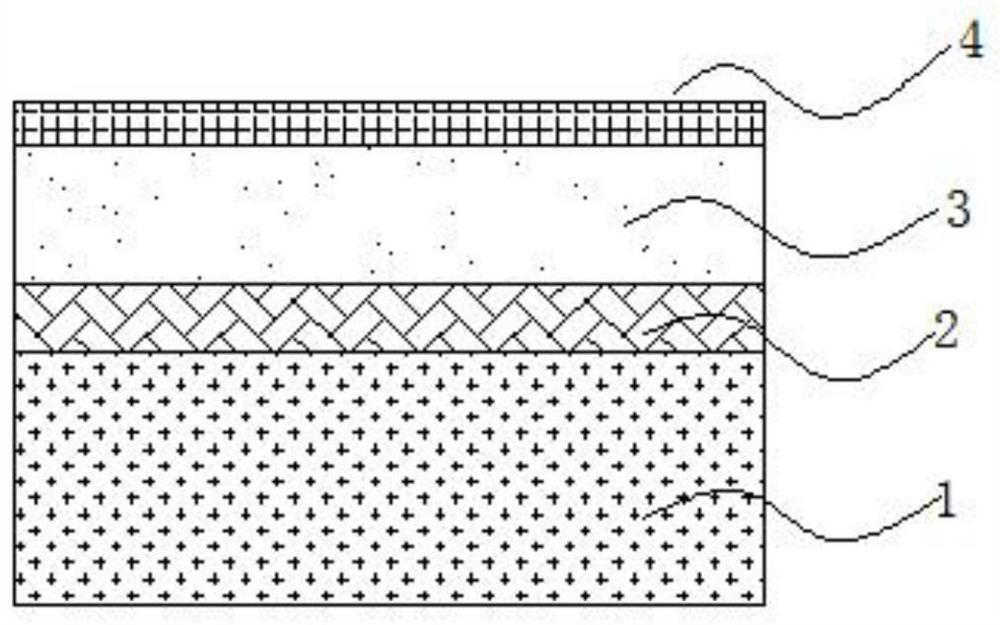

[0034] Step 1: Select the base surface 1, which is a smooth surface of a wooden board or a porcelain plate;

[0035] Step 2: Spread the adhesive evenly on the base surface and let it air dry;

[0036]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com